Dedicated clamp for abrasive buff stick

A special fixture and grinding rod technology, applied in the direction of the work carrier, can solve the problems of low processing production efficiency, scrapped internal materials, low work efficiency, etc., and achieve the effects of high work efficiency, easy clamping, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

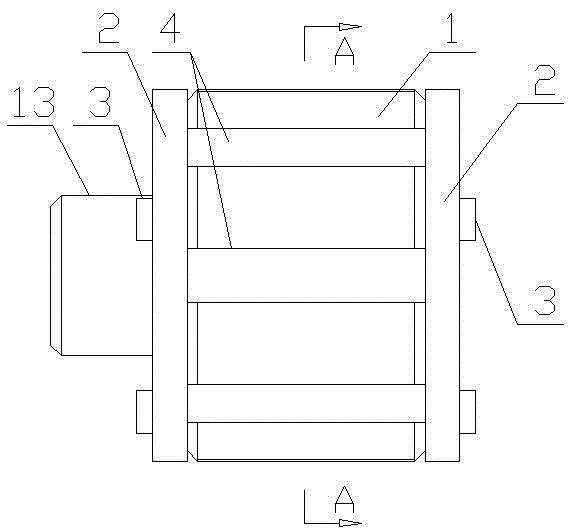

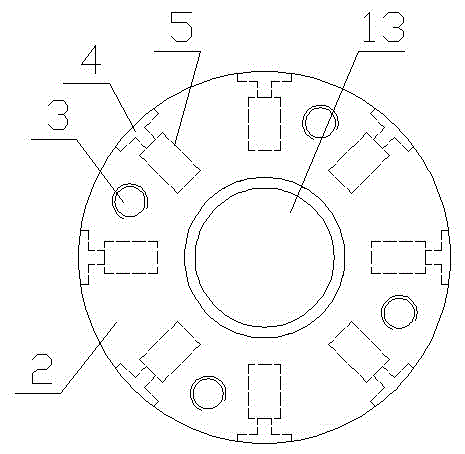

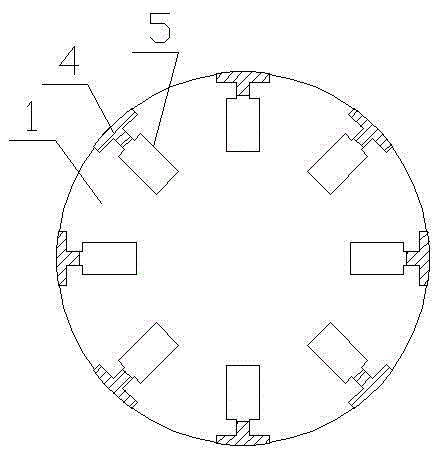

[0025] Example 1, such as Figure 1-7 The special fixture for grinding bars shown includes a fixture body 1, one end of the fixture body 1 is provided with a cylindrical step 13, and eight connected grinding bar installation grooves 11 and magnet installation grooves are evenly distributed on the circumferential surface of the fixture body 1. 12. The bottom of the grinding rod installation groove 11 is in communication with the top of the magnet installation groove 12, the grinding rod installation groove 11 is T-shaped, and the magnet installation groove 12 is square. A magnet 5 is arranged in the magnet mounting groove 12, a grinding rod 4 is installed in the grinding rod installation groove 11, and the bottom of the grinding rod 4 is adsorbed together with the magnet 5, and the magnet 5 plays a radial positioning effect on the grinding rod 4, and the grinding rod 4 is connected to the magnet 5. The shape of the grinding bar installation groove 11 is adapted, and the outer s...

Embodiment 2

[0028] Example 2, such as Figure 8-10 The special clamp for grinding bars shown is different from Embodiment 1 in that: the circumferential surface of the clamp body 6 is evenly provided with twelve connected grinding rod installation grooves 61 and magnet installation grooves 62, and the clamp body 6 A cylindrical step 63 is provided at one end.

[0029] Not limited to the above-mentioned embodiments, the maximum outer diameter of the fixture body and the number of the grinding bar installation slots and magnet installation slots in the present invention depend on the arc outer diameter of the grinding bar 4 and the width of the grinding bar 4, and can also be processed according to customer needs Fixture body with 4 or 16 grinding rod installation slots and magnet installation slots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com