Elevator without engine room

A machine room-less elevator and elevator technology, which is applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of high energy consumption, large transmission loss and high cost, achieve convenient installation and use, reduce energy consumption, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

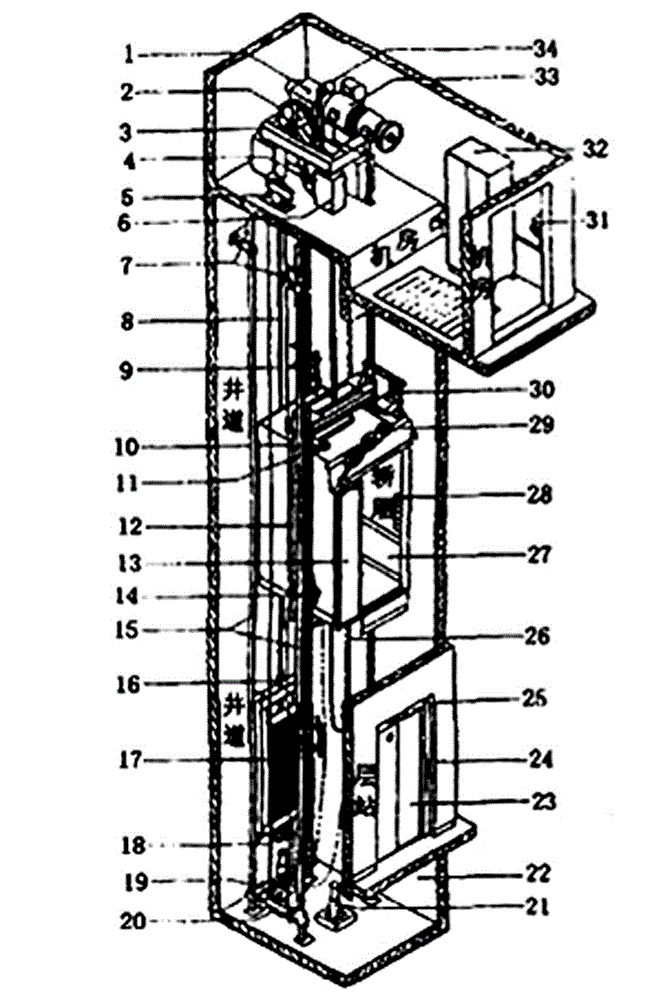

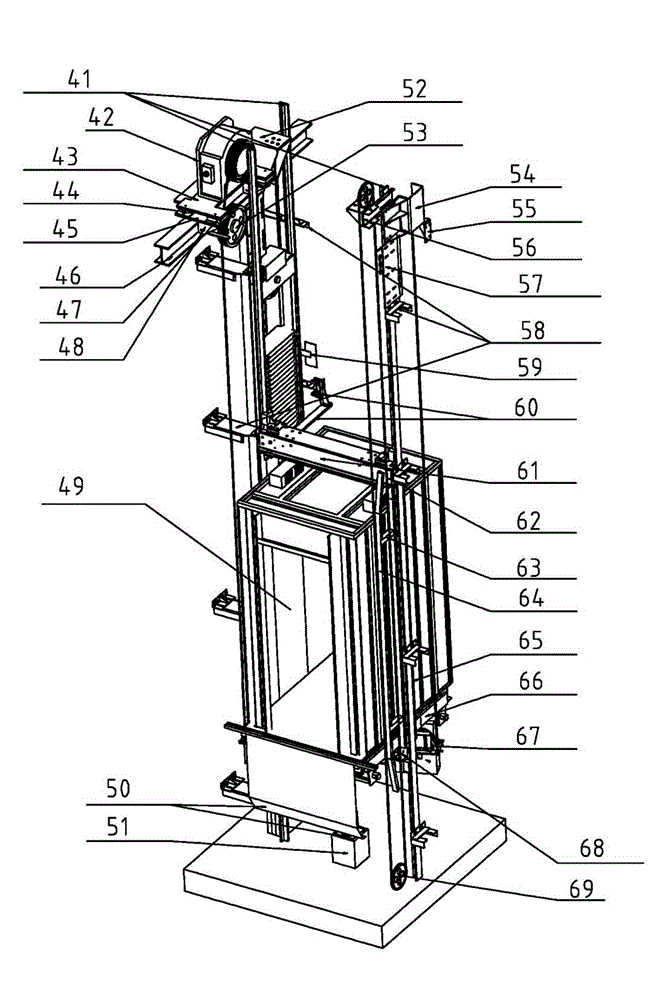

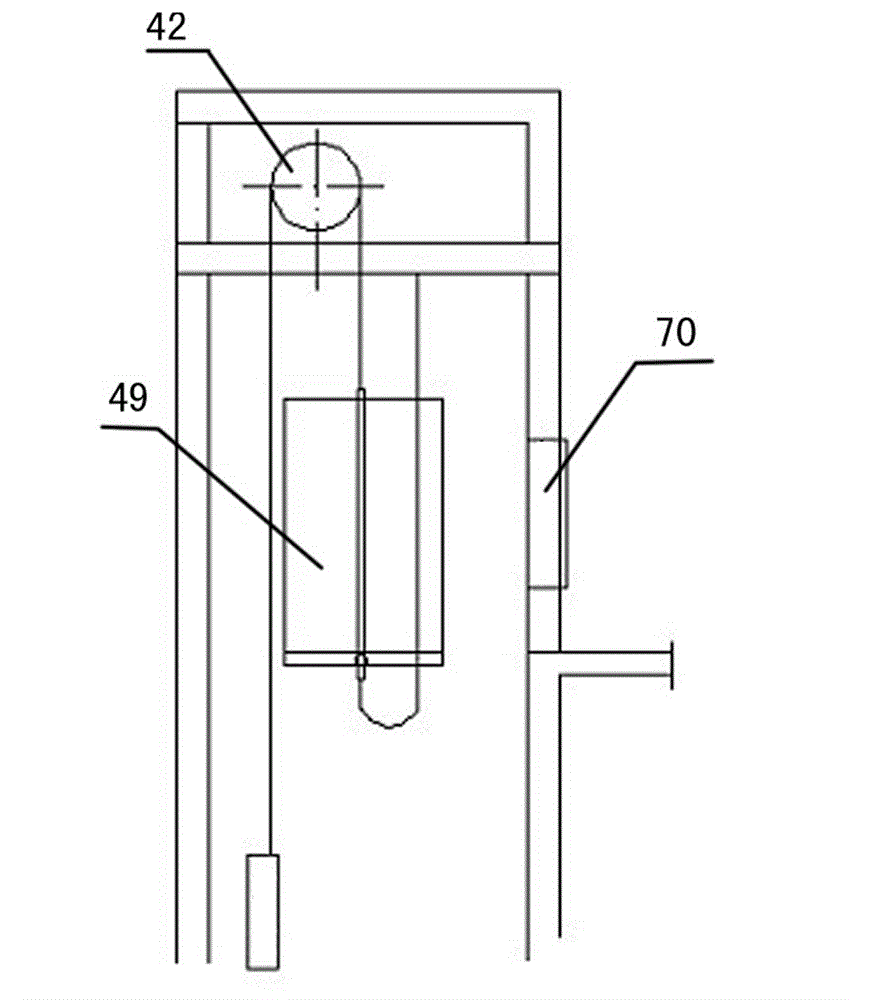

[0037] The machine-roomless elevator of the present invention is a new type of elevator produced with the development of traction technology and the requirements of energy saving and environmental protection. It is to install the traction machine and speed limiter among the elevator components in the elevator shaft to control The cabinet is installed beside the door of the top floor of the elevator, thus compressing the machine room in the elevator shaft.

[0038] The improvement of the installation structure of machine room-less elevators is different from that of machine-room elevators. In the case of machine-room-less elevators with higher transmission ratio, 2:1 rewind wheels are installed on the two corners of the lower middle of the car to save the space on the top of the hoistway and reduce the height of the top floor.

[0039] Because the conservative coefficient of the traction machine of the machine-roomless elevator is small, the moment of inertia of the entir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com