Method using spent grains of white liquor for preparing active carbon

A technology for preparing activated carbon and liquor, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of polluting the surrounding environment, affecting normal production, wasting resources, etc., and achieve environmental pollution reduction, excellent adsorption performance, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1. The desiliconization step of waste

[0017] Add 500mL of 2mol / L NaOH solution to 100g of waste grains, heat on an electric heating mantle, condense and reflux for 1 hour, then filter, wash the filter residue until neutral, and dry to obtain 32.6g of desiliconized waste grains. The yield of desiliconization of dregs is 32.6%

[0018] 2. Desiliconization and carbonization and activation steps:

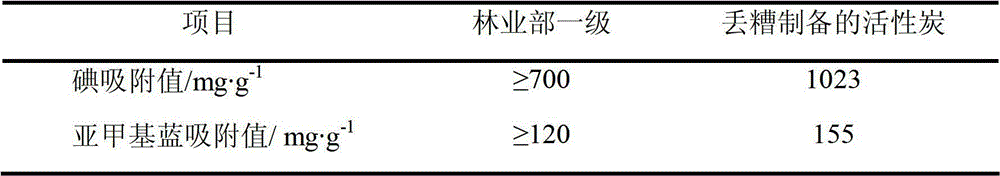

[0019] Add 25mL of zinc chloride solution with a mass concentration of 50% to 5g of desiliconized grains (the ratio of solid to liquid is 1:5), place it in a muffle furnace for carbonization and activation at 500°C for 40 minutes, and then successively pass through a mass concentration of 5-10 % dilute hydrochloric acid, washed to neutrality, filtered, dried and ground to obtain 1.39g of activated carbon finished product. The finished product yield of activated carbon prepared by desiliconization and waste was 27.9%. The finished product yield of activated carbon prepared by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com