Preparation process for producing tobacco organic compound fertilizer by utilizing animal manure

A livestock and poultry manure and preparation technology, which is applied to the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts, can solve the problems of late start in the production and application of compound fertilizers, save manpower and fertilization costs, and improve utilization rate, and the effect of preventing and controlling tobacco diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

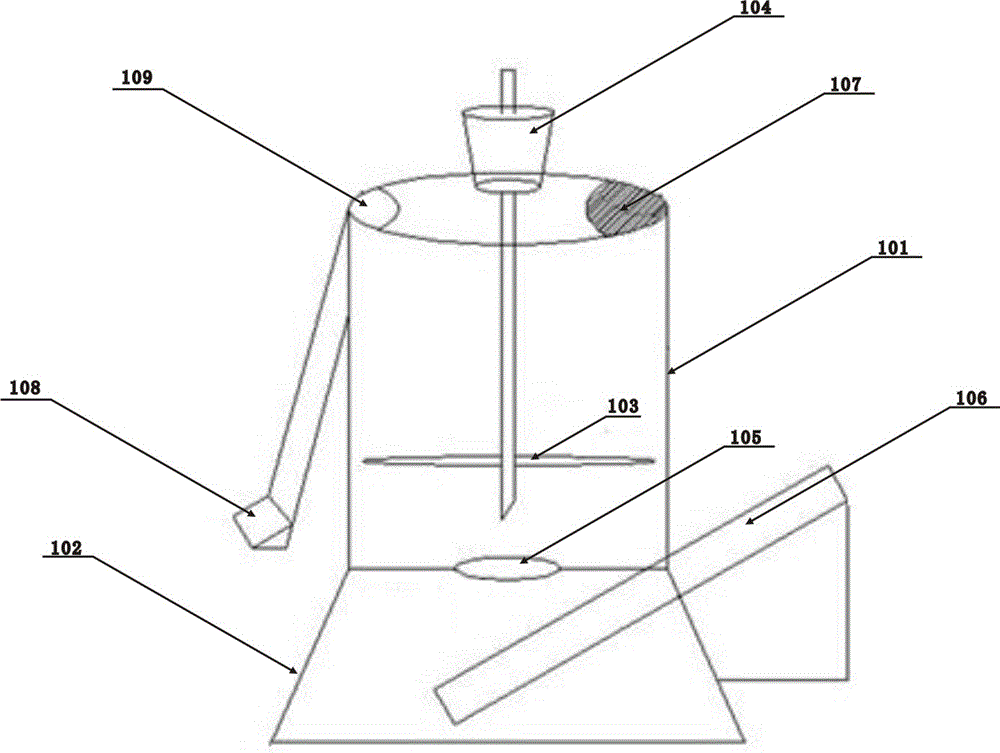

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

[0022] The present invention hereby provides a preparation process for making tobacco organic compound fertilizer by utilizing livestock and poultry manure,

[0023] The first stage of fermentation process: fresh pig manure is mixed with straw or fungus residue, and then put into a stainless steel fermenter for fermentation operation, heated to 70-90 degrees in the fermenter, stirring operation is carried out at the same time during the heating process, stirring makes The temperature of the contents is uniform, killing harmful bacteria and insect eggs. After heating for a certain period of time, the power is cut off, and the heat energy of fermentation organisms is used to maintain 70-90 degrees, and the tank will be released after 12-24 hours;

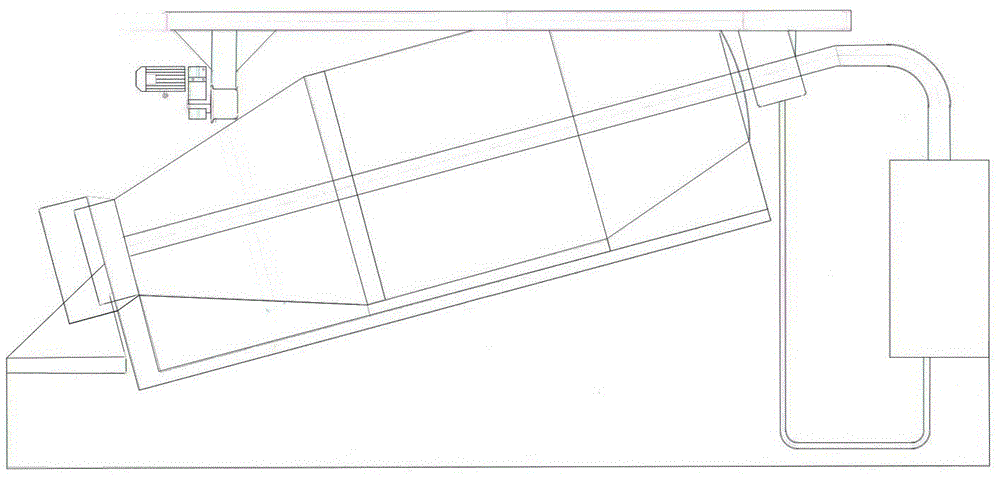

[0024] In the second stage, an air pump and an air pipeline are used for high-pressure aerated accumulation fermentation to further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com