Preparation process of conductive halogen-free flame-retardant PA/PE(polyamide/polyethylene) alloy material

A technology of alloy materials and metals, applied in the field of polymer material preparation, to achieve the effects of improving preparation efficiency, eliminating static electricity, and less process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

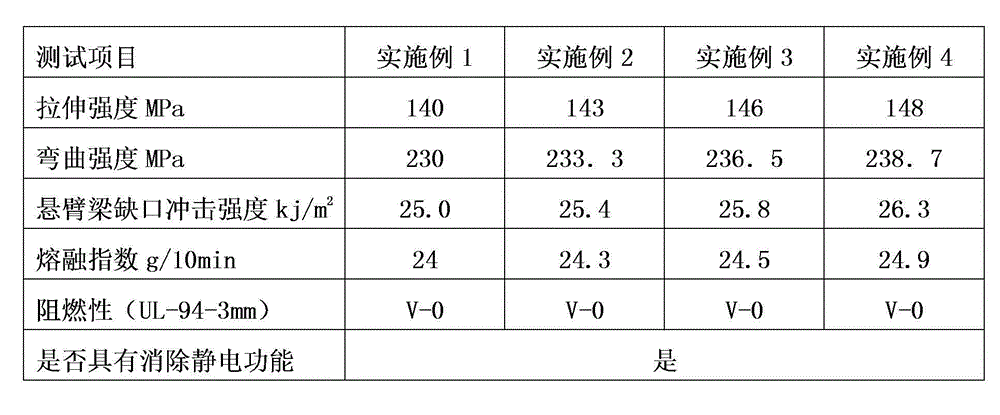

Examples

Embodiment 1

[0018] A) To prepare granulation materials, first weigh 180 parts of nylon 6 (PA) resin, 70 parts of medium density polyethylene resin (PE), and the coupling agent is isopropyl 2 parts of triethoxysilane, 20 parts of surface-treated aluminum hydroxide as metal oxide, 50 parts of melamine urate as solid phosphate, and 20 parts of conductive carbon fiber as carbon nanotubes were put into a high-speed mixer and mixed for 20 minutes. The rotating speed of the machine is 600n / min, and then drop into the antioxidant that weighs by parts by weight namely tetrakis [methyl-β- (3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.7 90 parts of alkali-free chopped glass fibers with a length of 3 mm and 1.2 parts of monostearic acid amide as a surface modifier, continue mixing for 5 min to obtain granulated material;

[0019] B) Granulation, put the granulated material obtained in step A) into a twin-screw extruder for melt extrusion, the temperature zones of the screws ...

Embodiment 2

[0021] A) To prepare granulation materials, first weigh 190 parts of nylon 6 (PA) resin, 55 parts of medium density polyethylene resin (PE) and 55 parts of medium density polyethylene resin (PE), and the coupling agent is isopropyl 1.5 parts of triethoxysilane, 24 parts of surface-treated aluminum hydroxide as metal oxide, 40 parts of melamine urate as solid phosphate, and 15 parts of conductive carbon fiber as carbon nanotubes were put into a high-speed mixer and mixed for 10 minutes. The rotating speed of the machine is 1000n / min, and then drop into the antioxidant that takes by weight parts namely tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.9 80 parts of alkali-free chopped glass fibers with a length of 3 mm and 1.6 parts of monostearic acid amide as a surface modifier, and continue mixing for 10 minutes to obtain granules. All the other are the same as the description to embodiment 1.

Embodiment 3

[0023] A) To prepare pellets, first weigh 200 parts of nylon 6 (PA) resin, 60 parts of medium-density polyethylene resin (PE), and the coupling agent is isopropyl 2.5 parts of triethoxysilane, 27 parts of surface-treated aluminum hydroxide as metal oxide, 45 parts of melamine urate as solid phosphate, and 20 parts of conductive carbon fiber as carbon nanotubes were put into a high-speed mixer and mixed for 15 minutes. The rotating speed of the machine is 1500n / min, and then drop into the antioxidant that is weighed by parts by weight i.e. tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 1.5 95 parts of alkali-free chopped glass fibers with a length of 3 mm and 2 parts of monostearic acid amide as a surface modifier, and continue mixing for 7 minutes to obtain granules. All the other are the same as the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com