Hot blast heater realizing preheated combustion of horizontal spraying heat accumulator of premixed air flow of gas and air

A technology of air premixing and horizontal injection, applied in the direction of brick blast furnaces, etc., can solve the problems of uneven mixing, uneven air distribution, complex burner structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

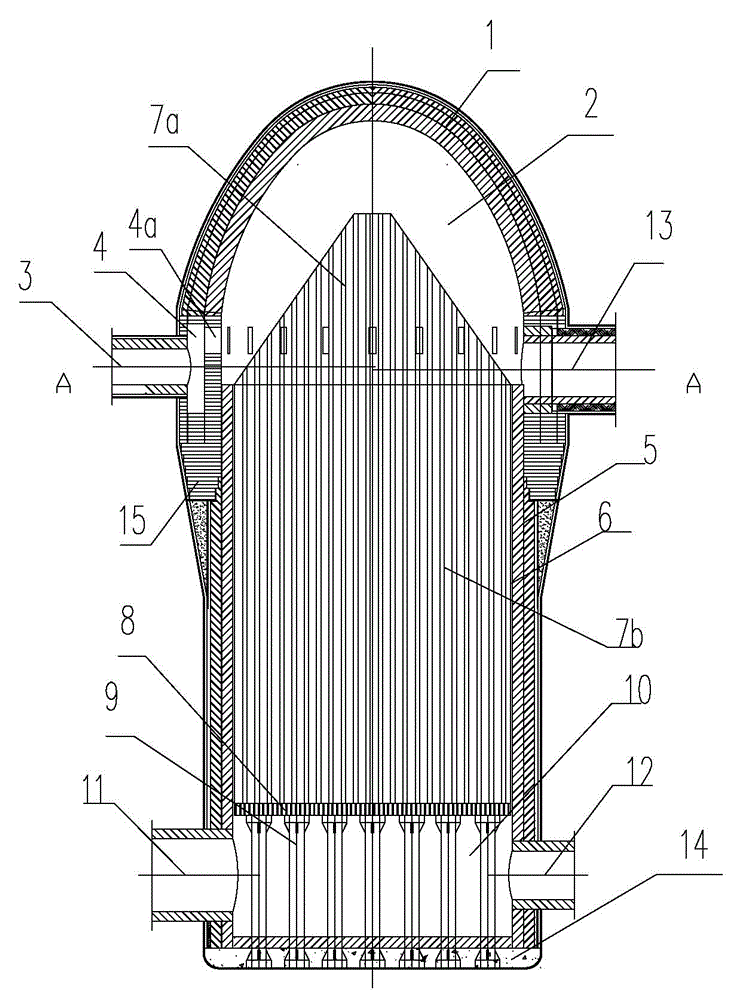

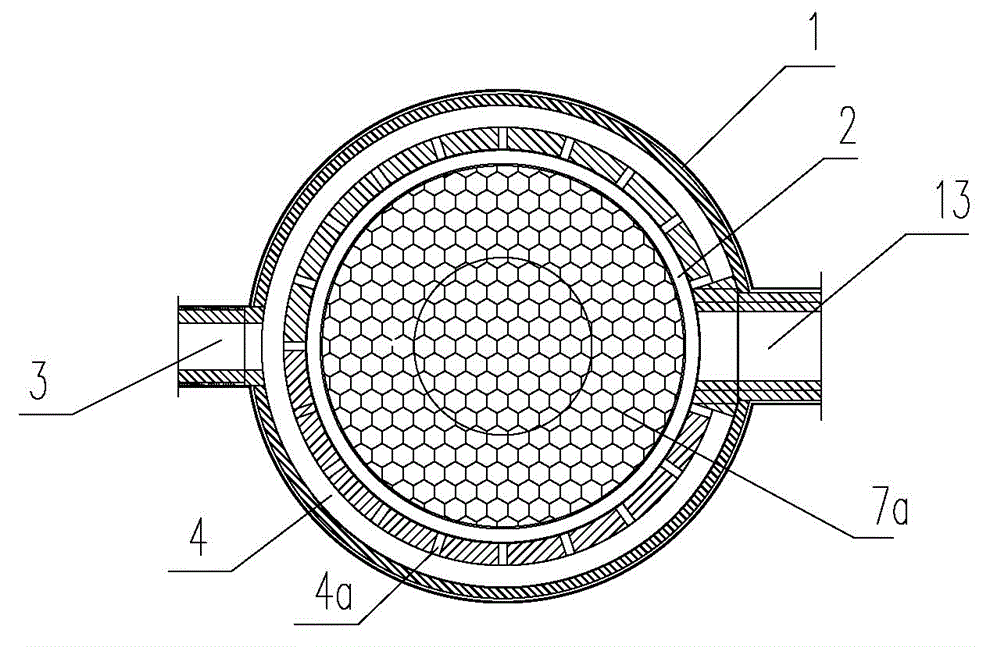

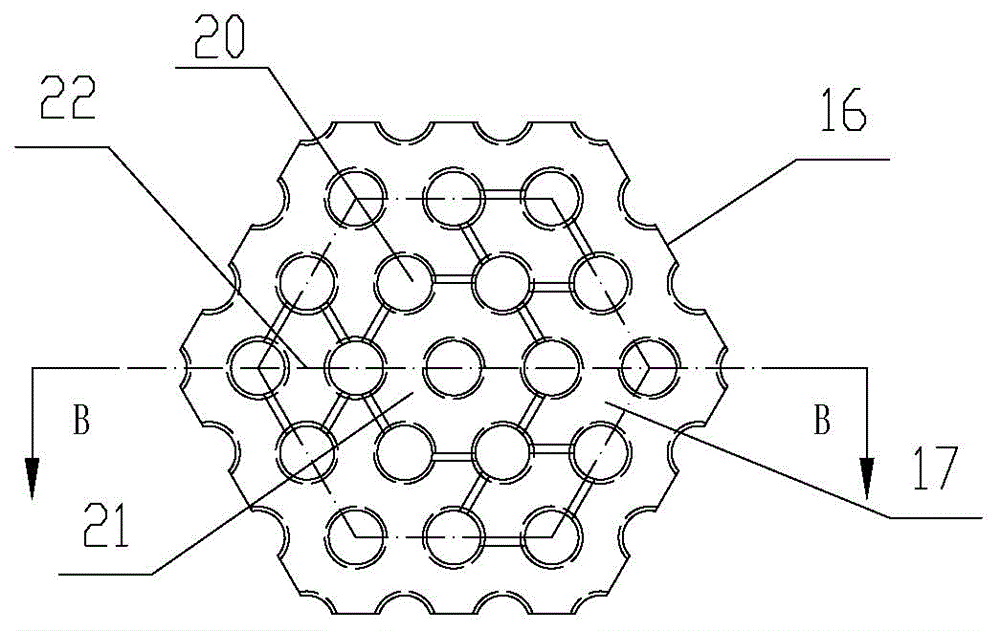

[0012] Depend on Figure 1-Figure 5 Given, the present invention includes a combustion chamber wall 1, a combustion chamber 2, a regenerator, a mixed air intake pipe 3, a mixed air distribution ring 4, a mixed air horizontal nozzle 4a, a hot blast stove wall 5, a regenerator 6, Furnace grate 8 and its support column 9, cold air chamber 10, flue gas outlet pipe 11, cold air inlet pipe 12, hot air outlet pipe 13, furnace bottom 14, and labyrinth connection structure 15 between the combustion chamber and the regenerator wall. The chamber wall 1 is composed of a spherical or ellipsoidal vault above and a cylinder below. The space in the combustion chamber wall is the combustion chamber 2. Hot air is arranged on the cylinder of the combustion chamber wall perpendicular to its axis. Outlet pipe 13 and mixed air inlet pipe 3, there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com