Mechanical resonance deicing device

A mechanical and ice layer technology, applied in cleaning methods, snow surface cleaning, construction, etc., can solve the problems that the vibration frequency of the ice breaking vibrating hammer cannot be adjusted, the deicing efficiency is not ideal, and it is difficult to deicing, so as to achieve thorough deicing, Easily broken, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

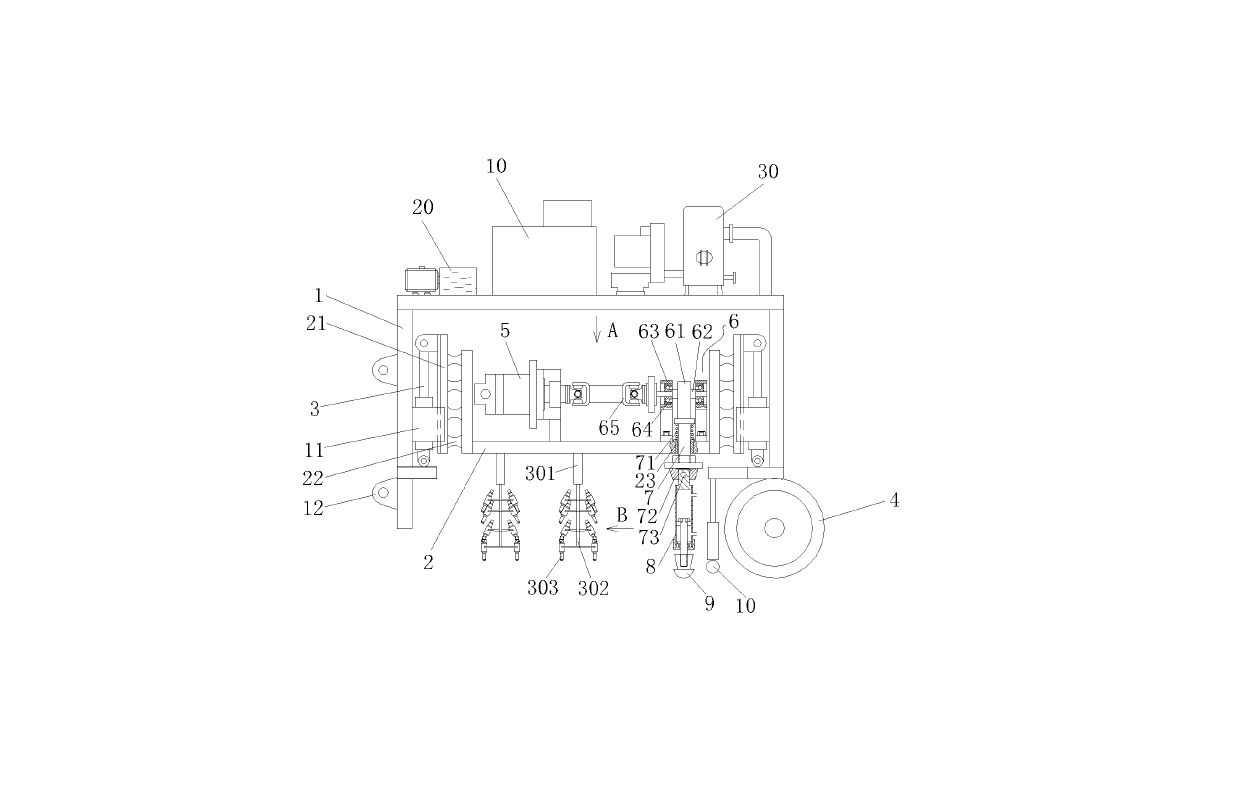

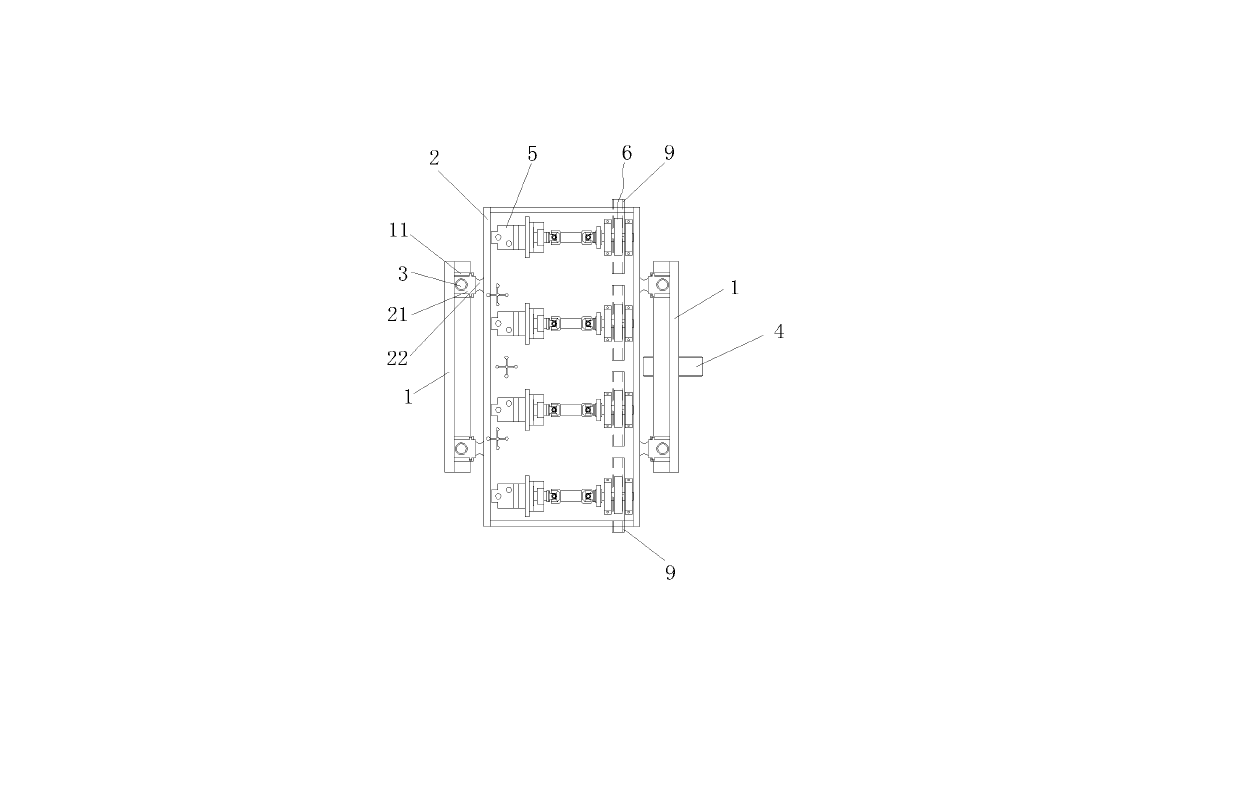

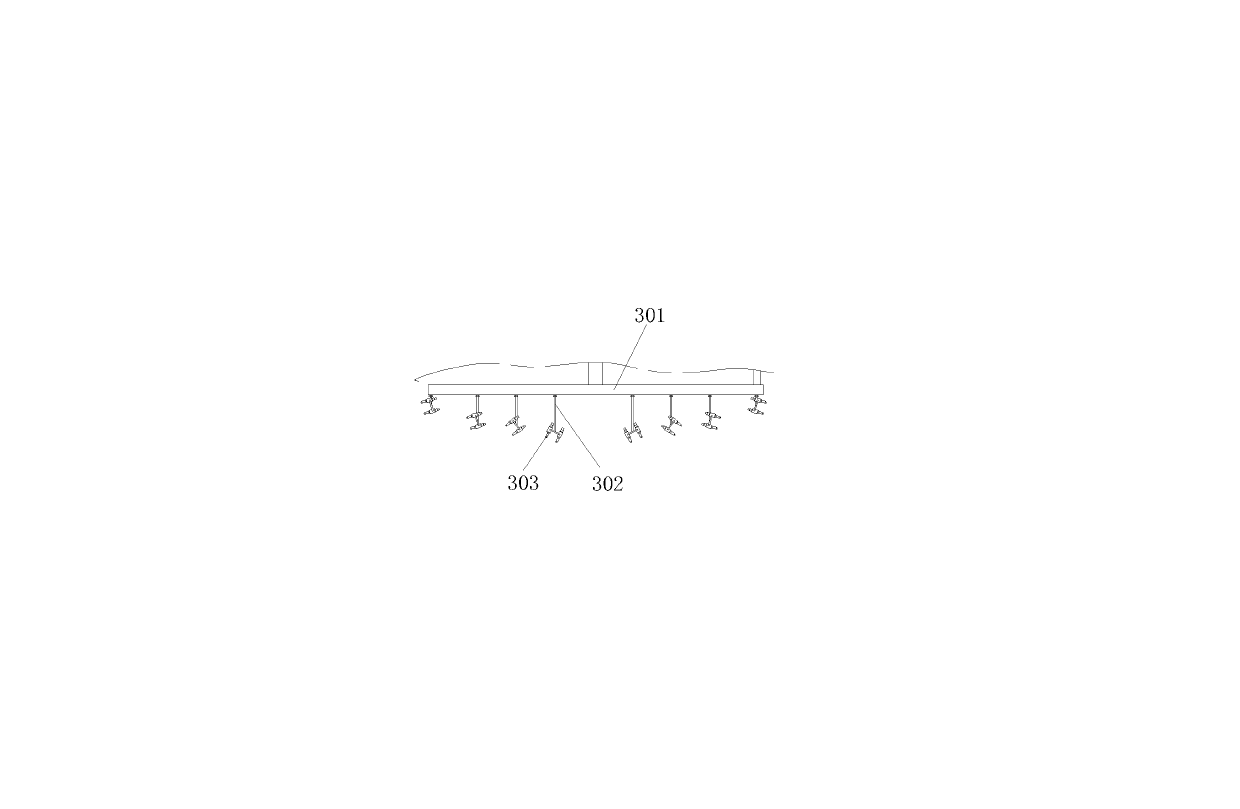

[0030] Embodiment 1. Figure 1 to Figure 6 As shown in the figure, a mechanical resonance deicing device includes a main frame 1 and a support frame 2. The two sides of the support frame 2 are connected with four lifting cylinders 3 arranged on the main frame 1 through two support arms 21 respectively. A shock-absorbing block 22 is installed between both sides of the frame 2 and each support arm 21. Each support arm 21 moves up and down along the sliding track 11 provided on the main frame 1. One side of the main frame 1 is provided with a connecting seat 12. The lower part of the other side of the frame 1 is equipped with a moving wheel 4;

[0031] The upper part of the support frame 2 is provided with four eccentric vibration mechanisms 6 driven by the hydraulic motor 5 at intervals, and the lower part of each eccentric vibration mechanism 6 is connected with a vibration rod 7 that can reciprocate up and down. The mechanism 6 includes a rotating shaft 62 which is worn on th...

Embodiment 2

[0038] Embodiment two, Figure 8 , Figure 9 , Figure 10 As shown, the difference from the first embodiment is that each eccentric vibration mechanism 6 is driven by the motor 60, the hydraulic station 20 removes the flow valve and the hydraulic motor part, and the microcomputer controller 103 measures the natural frequency of the ice layer according to the The speed of the motor 60 is controlled by the governor 105 so that the vibration frequency of each vibrating rod 7 is the same as the natural frequency of the ice layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com