Submerging jet flow testing box and testing method

A test method and test box technology, which is applied in the testing of mechanical components, fluid dynamics testing, testing of machine/structural components, etc., can solve the problem that non-contact methods cannot be used for jet structures, staying, and it is difficult to record submerged abrasive jets The acceleration mechanism of medium abrasive particles and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

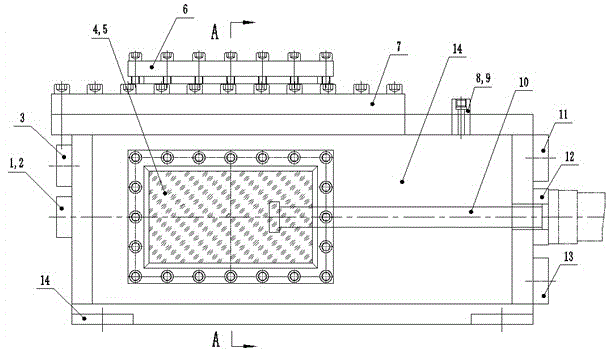

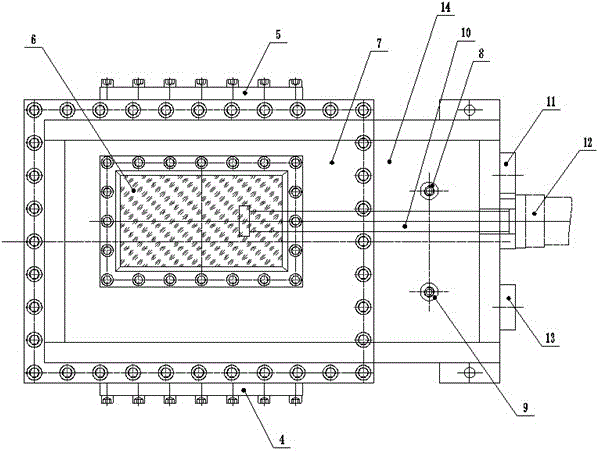

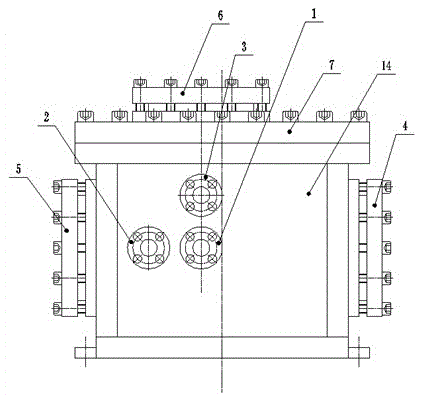

[0016] see figure 1 , figure 2 , image 3 with Figure 4 , the test box includes a box body 14, glass windows 4, 5, 6, jet water inlets 1, 2, 3, holder 10, feeding device 12, pressure gauge interface 8, air release port 9, liquid flow valve port 11 And discharge port 13 etc.

[0017] The glass window 6 is on the top cover of the casing, surrounded by steel plate pressing, connected with the top cover 7 by bolts, and the top cover 7 is connected with the casing 14 by bolts. Glass window 4,5 is on the front and back wall of casing, and edge is pressed with steel plate all around, also connects respectively on the casing 14 by bolt. During the test, the laser of the 3DPIV system (three-dimensional laser particle imaging velocimeter) can be injected into the jet fluid in the test box through the glass window 6, and the high-speed camera can take pictures of the jet fluid structure through the glass window 5, and the experimenter can directly pass through the glass window 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com