Dual-phase stainless steel crystalline grain structure display method

A technique for duplex stainless steel, display method, application in the direction of material analysis, measuring devices, instruments, etc. using wave/particle radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment: adopt experimental technology of the present invention, the organization after solid solution treatment of S32750 super duplex stainless steel has been observed and analyzed, and concrete implementation process and result are as follows:

[0023] The samples after solid solution at different temperatures are processed into a plate-shaped test block with a length of 15mm * 10mm width * 4mm thickness. The surface to be tested is a long and wide surface. First, the surface of the plate is mechanically polished, and the surface roughness is GB / T1031—95 Ra : 0.020—0.050;

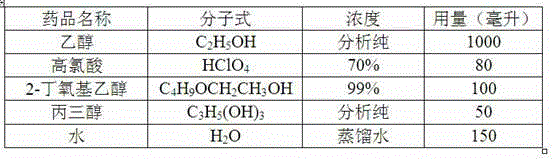

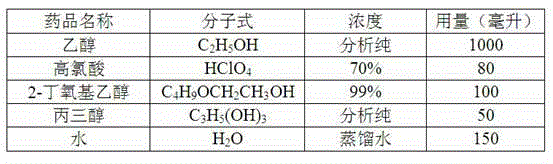

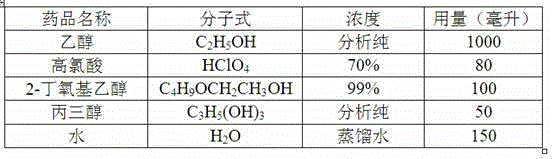

[0024] Select perchloric acid as the electrolytic polishing solution of the oxidizing agent, and the composition of the polishing solution is based on 1000 milliliters of ethanol, as shown in the following table:

[0025]

[0026] Then electropolishing was performed on a Struers Lectropol-5 electropolishing instrument, the voltage of the electropolishing was 32V, the polishing time was 12 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com