Thermal diffusivity sensor chip with silicon cup structure and preparation method of thermal diffusivity sensor chip

A sensor chip and thermal diffusivity technology, which is applied in the field of thermal diffusivity sensor chips, can solve the problem of not considering the influence of heat capacity and diameter of thermal probes, and achieve more authentic and reliable measurement results, fast response, and good thermal insulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The thermal diffusivity sensor chip of the silicon cup structure of the present invention and its preparation method are described in detail below in conjunction with the accompanying drawings:

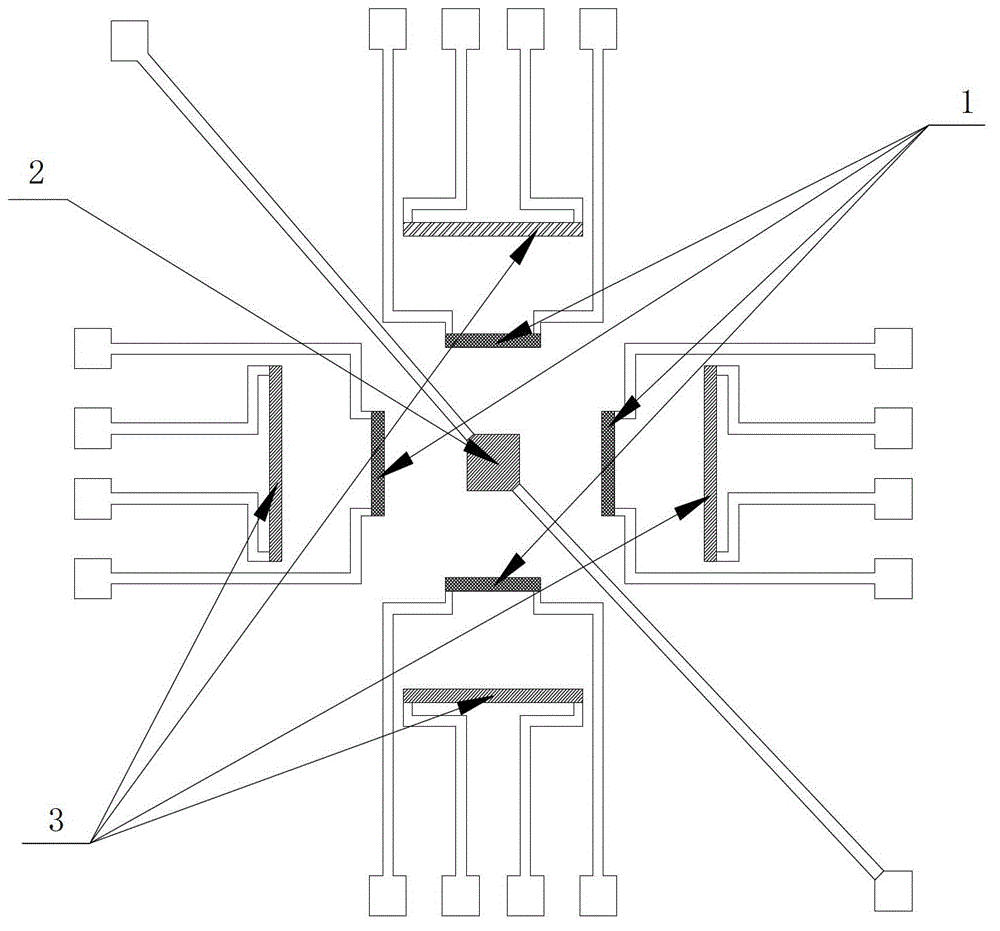

[0034] refer to figure 1 , is the plane structure diagram of the sensor chip of the present invention, the temperature sensor 2 of the thermal diffusivity sensor chip of a silicon cup structure of the present invention is located at the center position, and 4 heaters 1 and 4 temperature sensors 3 are centered around the temperature sensor 2 form two squares, and the metal leads respectively lead the two ends of the heater and the two ends of the temperature sensor to the pads. By heating the heater 1, the temperature sensors distributed in the periphery and the center produce accurate and rapid temperature response. The heater and temperature sensor are made of chromium-nickel-platinum multilayer metal film.

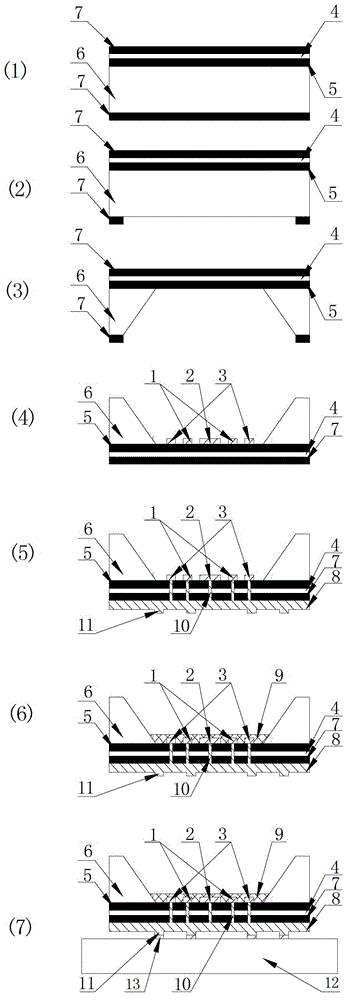

[0035] refer to figure 2 , the lower surface of the SOI wafer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com