Overvoltage measuring sensor for overhead transmission line based on coupling electric field

An overhead transmission line and voltage measurement technology, which is applied in the direction of measuring current/voltage, voltage divider, measuring device, etc., can solve the problem of reducing the electrical performance of voltage dividing capacitors and matching resistors, failing to monitor overvoltage of overhead transmission lines, and destroying voltage division Problems such as capacitors and matching resistors have been eliminated to achieve the effects of eliminating potential safety hazards, facilitating popularization and application, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

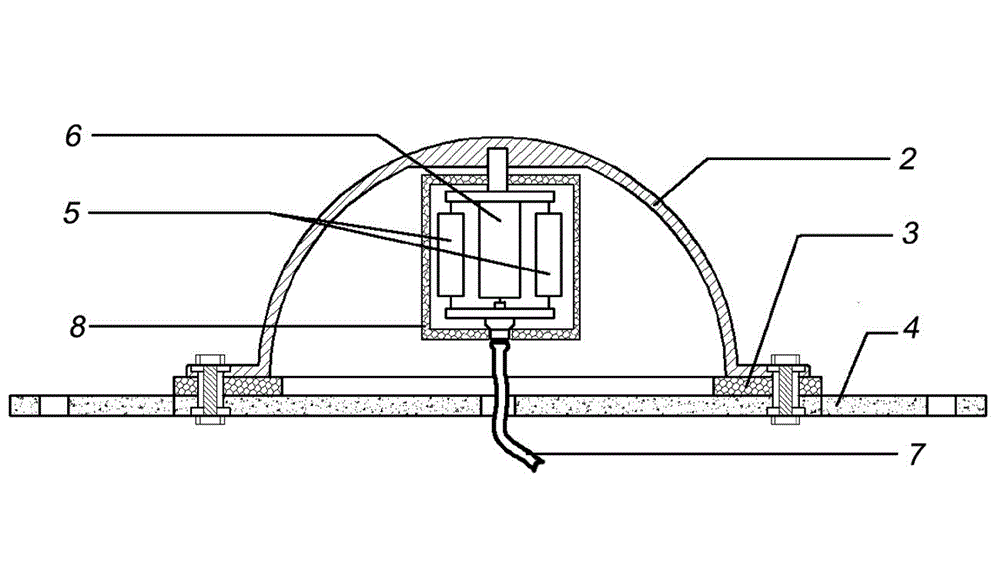

[0032] Such as Figure 1~3 As shown, a sensor for overvoltage measurement of 110kV overhead transmission lines based on coupling electric field mainly includes sensor housing 2, insulating pad 3, fixing plate 4, voltage dividing capacitor group 5, matching resistor 6, coaxial cable 7 , Inner shielding shell 8, data acquisition unit 10, etc.

[0033] The material of the sensor housing 2 is copper, and the shape of the sensor housing 2 is hemispherical with an outer flange at the bottom. The inner diameter of the hemispherical sensor housing 2 is 180mm, the thickness is 5mm, the width of the outer flange is 20mm, and the thickness is 5mm, and a screw blind with a hole depth of 5mm is set at the axis of the top thickened part in the shell. hole. The inner shielding shell 8 is installed in the sensor housing 2 . The voltage dividing capacitor group 5 and the matching resistor 6 are installed in the inner shielding shell 8; the voltage dividing capacitor group 5 and the matching...

Embodiment 2

[0040] A sensor for overvoltage measurement of overhead transmission lines based on coupled electric fields of 500kV is the same as in Embodiment 1, wherein: the material of the sensor housing 2 is stainless steel, and the inner diameter of the hemispherical sensor housing 2 is 400mm, The thickness is 7mm, the width of the outer flange is 30mm, and the thickness is 15mm, and a screw blind hole with a depth of 8mm is set at the top of the shell; 12 circular grooves are evenly arranged on the outer flange of the sensor housing 2 Bolt through holes; the shortest distance between the sensor housing 2 and the bottom end of the sag of the jumper wire of the overhead transmission line 1 is 5m; the voltage dividing capacitor group 5 is formed by parallel connection of 4 commercially available non-inductive capacitors (a capacitor bank with a capacitance value of 0.04uF); the resistance value of the matching resistor 6 is 50Ω (matched with the coaxial cable); the hollow cylinder of the ...

Embodiment 3

[0042] A sensor for overvoltage measurement of overhead transmission lines based on coupling electric field of 1000kV, same as embodiment 1, wherein: the material of the sensor housing 2 is aluminum alloy, and the inner diameter of the hemispherical sensor housing 2 is 1000mm , the thickness is 10mm, the width of the outer flange is 40mm, the thickness is 20mm, and a screw blind hole with a depth of 10mm is set at the top of the shell; The bolt through hole of the slot; the shortest distance between the bottom end of the sensor housing 2 and the sag of the jumper wire of the overhead transmission line 1 is 10m; (a capacitor bank with a capacitance value of 0.08uF); the resistance value of the matching resistor 6 is 75Ω (matched to the coaxial cable); the hollow cylinder of the inner shielding shell 8 has a height of 100mm, an inner diameter of 110mm, and a thickness of 12mm, wherein the thickness of the aluminum sheet is 4mm; the material of the insulating pad 3 is epoxy glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com