1-watt 8db attenuation piece for aluminum oxide ceramic substrate

An alumina ceramic and alumina technology, applied in electrical components, circuits, waveguide-type devices, etc., can solve problems such as signals that do not meet actual requirements, reduce the generation of defective products, increase high and low temperature impact resistance, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

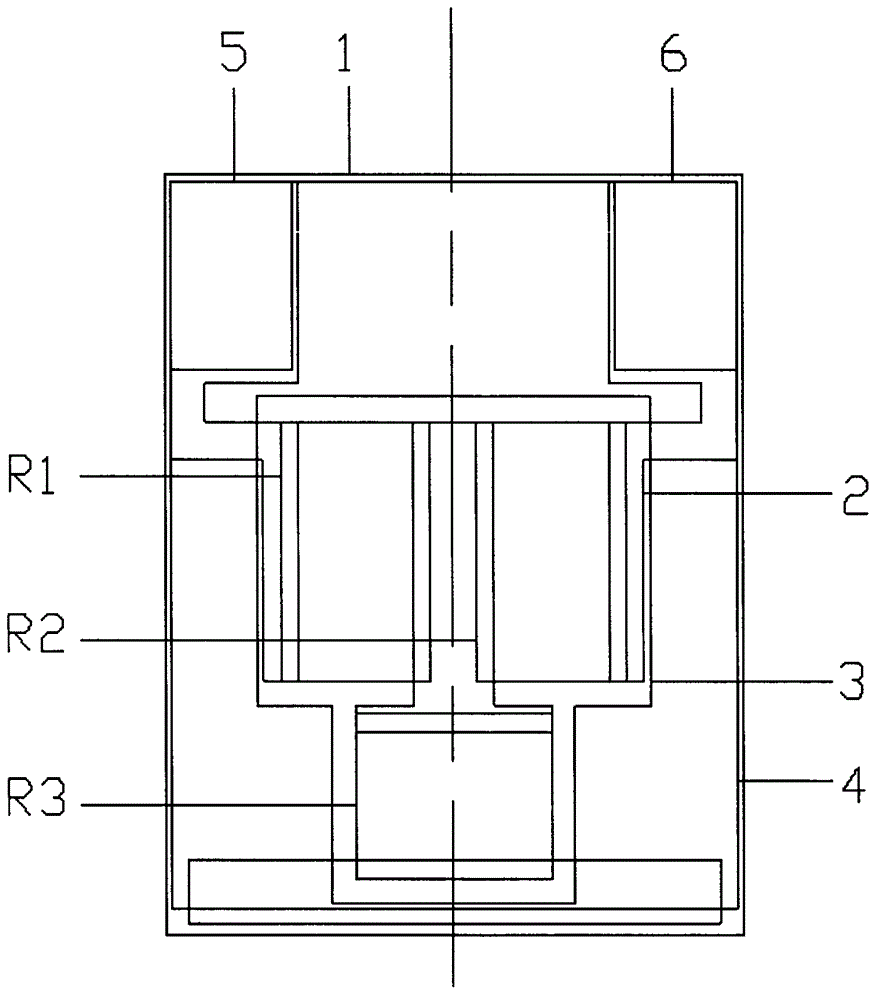

[0013] like figure 1 As shown, the alumina ceramic substrate 1 watt 8dB attenuator includes an alumina substrate 1 with a size of 2*3.5*0.635MM. The backside of the alumina substrate 1 is printed with a back guide layer, and the front side of the alumina substrate 1 is printed with wires. 2 and film resistors R1, R2, R3, film resistors R1, R2, R3 are connected by wires to form an attenuation circuit, and the attenuation circuit is electrically connected to the back conductive layer through silver paste, so that the attenuation circuit is grounded. The attenuation circuit is symmetrical along the center line of the aluminum oxide substrate, and a glass protective film 3 is printed on the film resistors R1, R2, R3, and a layer of black protective film 4 is also printed on the upper surface of the wire 2 and the glass protective film 3, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com