Copper aluminium wire transition crimping clamp

A technology of terminal clips and copper-aluminum wires, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of corrosion and peeling, poor reliability of crimping quality, poor contact, etc., to achieve strong oxidation resistance and corrosion resistance, Stable and reliable performance, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

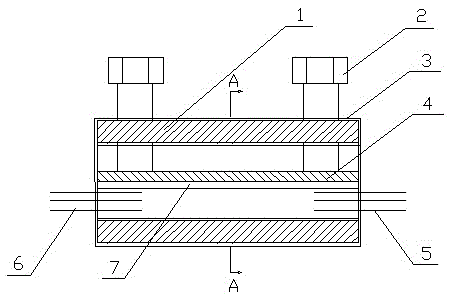

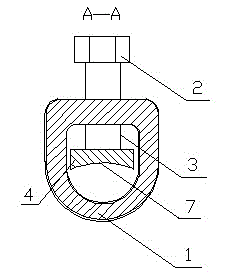

[0014] Such as figure 1 As shown: the copper-aluminum wire transition crimping clamp of the present invention has a tubular clamp body 1, and at least two compression screws 2 are installed on the clamp body 1 through threaded holes. In the wire clamp body 1, there is a wiring pressing plate 4 in contact with the end of the pressing screw 2, which is used for pressing the copper and aluminum wires 5, 6. The bottom side of the wiring pressing plate 4 is provided with an arc-shaped groove 7. Make it have the largest envelope contact area with copper and aluminum conductors 5 and 6. The clamp body 1 is made of silicon-magnesium-aluminum alloy, which can further increase the crimping area between the clamp body and the copper and aluminum wires by utilizing the elasticity of the silicon-magnesium-aluminum alloy, and can maintain a constant contact pressure between the wire and the wire clamp for a long time , Constant and sufficiently large contact pressure and maximized contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com