Guangdong style cured meat and production process thereof

A production process and Cantonese-style technology, which is applied in the field of Cantonese-style sausage and its production process, can solve the problems of inability to adjust the temperature, taste and flavor of finished bacon products, and achieve balanced and stable taste, uniform and more comprehensive contact, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

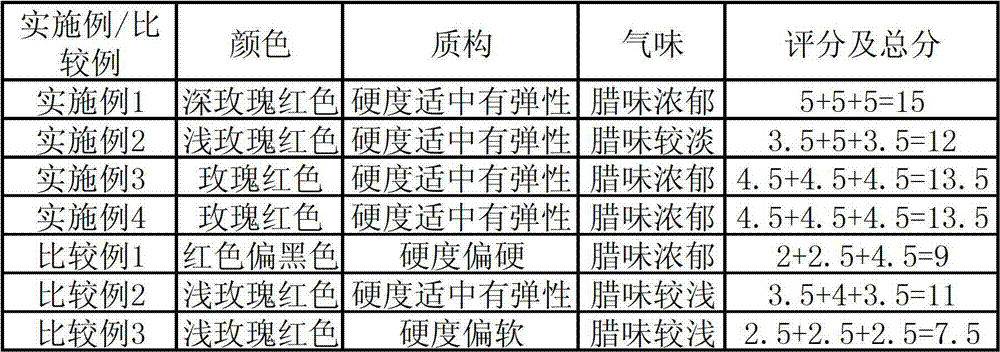

Embodiment 1

[0021] 1. Pork pre-treatment: Thaw frozen pork in a thawing pool with a water temperature of 40°C. After deboning, removing lymph, peeling, and separating fat and lean meat, cut them into fat and lean meat grains and lean meat grains respectively. The lean meat grain size is 3mm. , the fat particle size is 5mm;

[0022] 2. Cleaning: Soak the fat meat grains in warm water at 50°C for 10 minutes, wash off the grease, rinse with cold water, and drain;

[0023] 3. Pickling: Take 70kg of lean meat grains and 30kg of fat and lean grains and put them in a pickling basin, add the following ingredients: white sugar, salt, white wine, sodium nitrite, monosodium glutamate, the addition amount of the ingredients is: 10kg, 2kg , 2kg, 0.005kg, 0.3kg, stir evenly, marinate for 5 minutes;

[0024] 4. Filling: Send the marinated meat into the sausage enema machine for enema, piercing holes, tying grass ropes, and washing with cold water to obtain pork sausages;

[0025] 5. Drying: Put the po...

Embodiment 2

[0029] 1. Pork pre-treatment: Thaw frozen pork in a thawing pool with a water temperature of 40°C, cut into long strips of meat about 40cm in length, 4cm in width, and 2cm in thickness;

[0030] 2. Cleaning: Wash the above-mentioned strips of meat with warm water at 40°C to remove the grease, then rinse with cold water and drain for later use;

[0031] 3. Pickling: Take 100kg long strip meat, add the following ingredients: white sugar, salt, white wine, sodium nitrite, monosodium glutamate, the addition amount of the ingredients is: 15kg, 3kg, 4kg, 0.01kg, 0.4kg , stir evenly, marinate for 12 hours, turn it up and down every 30 minutes for the first 2 hours;

[0032] 4. Drying: Send the above-mentioned strips of meat into a hot air drying oven, bake at 50°C for 10 hours, then heat up to 58°C and bake for 25 hours, then cool down to 45°C and bake for 15 hours. Take it out to get Cantonese-style bacon. The moisture content of the bacon was measured to be 22%, and the color deve...

Embodiment 3

[0036] 1. Pre-treatment of duck meat: Thaw the frozen raw duck in a thawing pool with a water temperature of 40°C. The thawed raw duck is cut from the chest to remove bones, tendons, periosteum and hair, and the whole duck is set aside;

[0037] 2. Spice treatment: crush the anise into 30-mesh anise powder for later use;

[0038] 3. Pickling: Take 100kg whole duck and place it in a pickling basin, add the following ingredients: white sugar, salt, white wine, sodium nitrite, monosodium glutamate, anise powder, the addition amount of the ingredients is respectively: 13kg, 2.5kg , 3kg, 0.008kg, 0.4kg, 0.4kg, spread evenly, marinate for 24 hours, turn up and down twice on the way. Put the marinated whole duck in cold water to remove the salt for 2 hours;

[0039] 4. Drying: Put the above-mentioned whole duck into a hot air drying oven, bake at 50°C for 10 hours, then raise the temperature to 62°C and bake for 28 hours, then lower the temperature to 45°C and bake for 15 hours, tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com