Plane fuel tank inspecting robot based on connector structure and control method thereof

An aircraft fuel tank and robot technology, applied in the field of civil aviation, can solve problems such as aircraft/equipment damage, personnel poisoning, explosion, etc., and achieve the effects of excellent bending performance, easy maintenance and economic loss reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

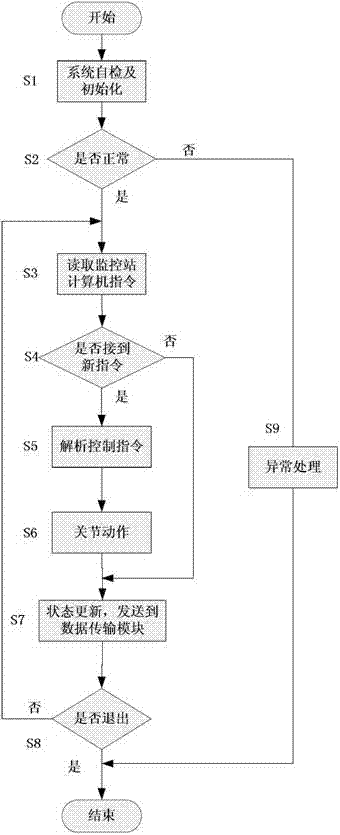

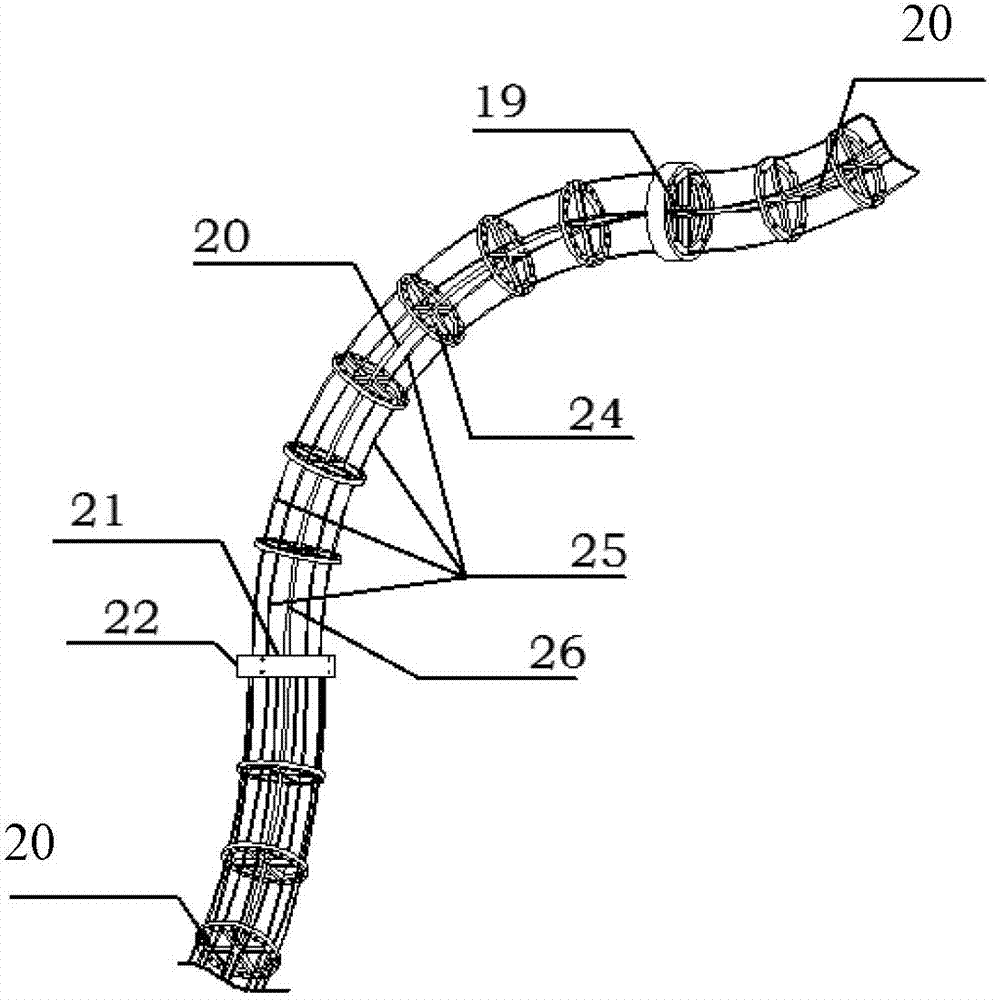

[0030] The aircraft fuel tank inspection robot based on the continuum structure and its control method provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

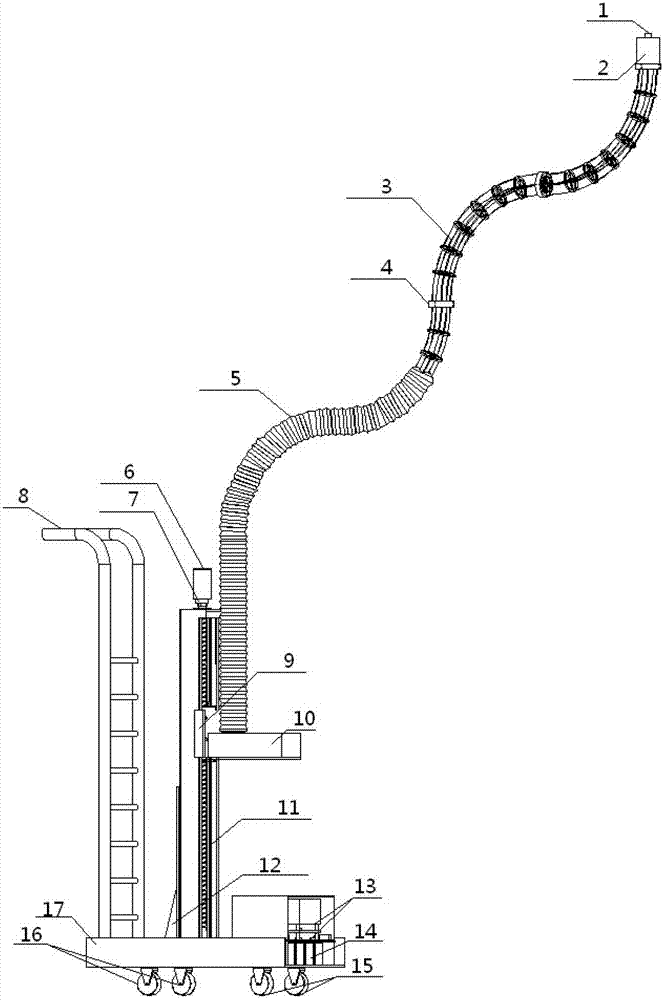

[0031] Such as Figure 1-Figure 4 As shown, the aircraft fuel tank inspection robot based on the continuum structure provided by the present invention includes a mobile platform, a lifting motion unit, a snake arm motion unit, a system control unit 13 and a power supply module 14;

[0032] Described mobile platform comprises base plate 17, two universal wheels 15 and two fixed wheels 16, and wherein base plate 17 is arranged horizontally, and two universal wheels 15 and two fixed wheels 16 are respectively arranged on the front and rear ends of the bottom of base plate 17. side;

[0033] The lifting motion unit includes a base 12, a linear module 11, a slider 9, a servo motor 6 and a coupling 7, which are used to provide a lifting func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com