Production method of fiber arrays

A production method and optical fiber array technology, which can be applied in the coating and other directions, can solve the problems of high processing technology requirements, low product qualification rate and high manufacturing cost, and achieve the effects of long processing cycle, simple process and high manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

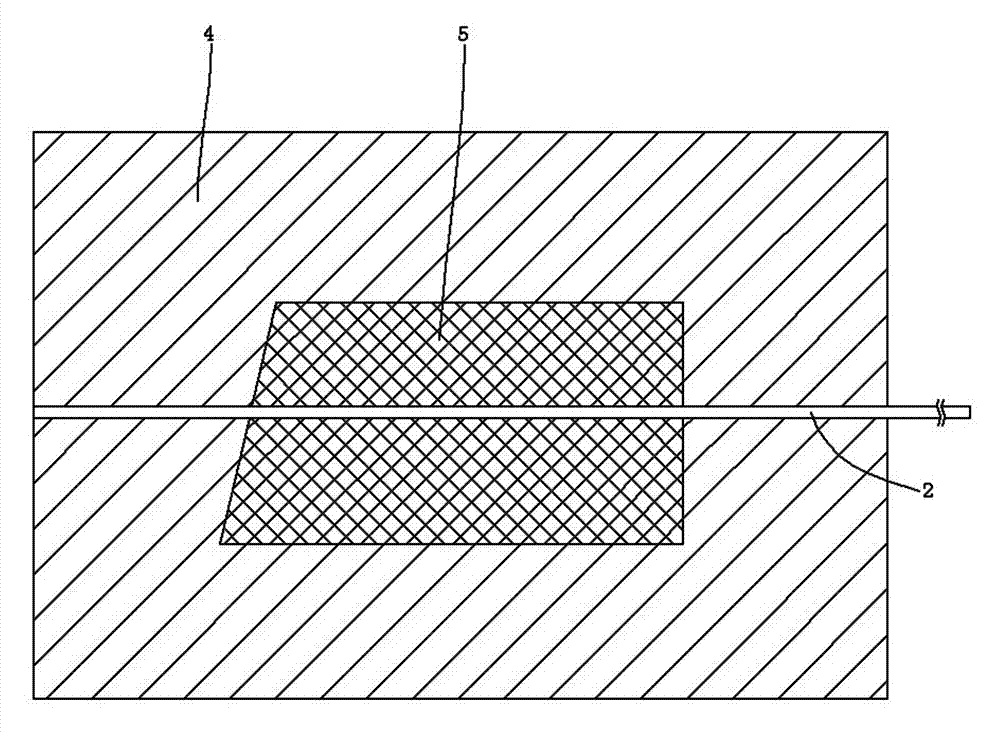

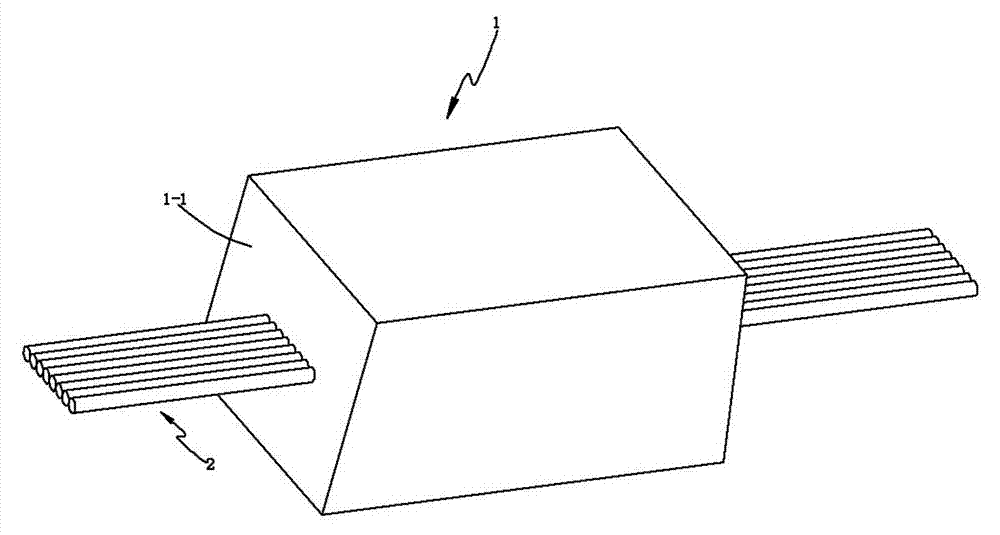

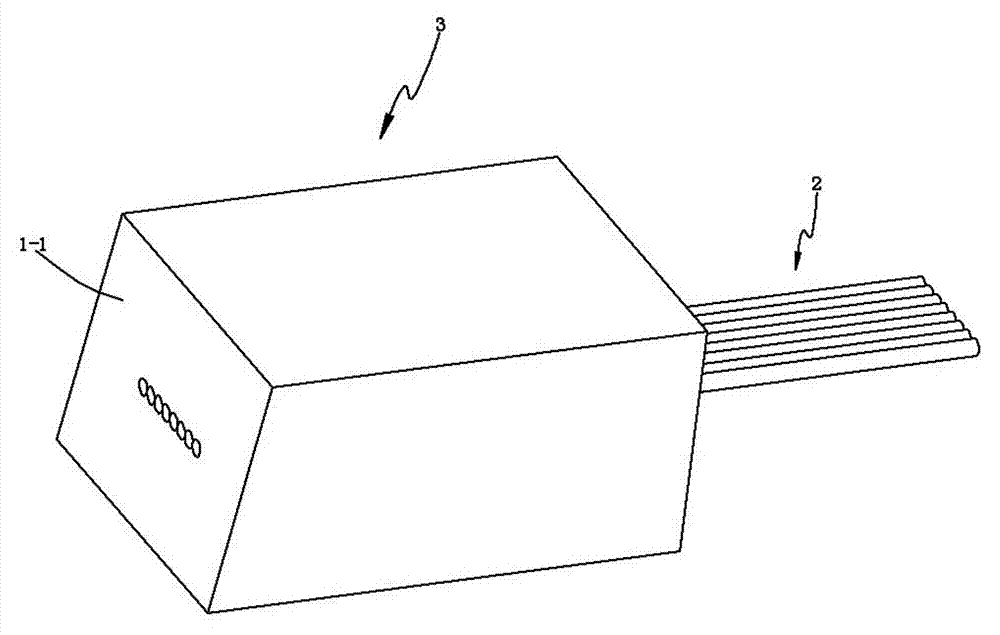

[0022] see Figure 1 to Figure 3 A production method of an optical fiber array shown, the production method comprises the following steps:

[0023] a. Using a common injection molding machine and a conventional injection molding process, using high molecular plastic as the injection molding material, placing the commercially available finished optical fiber ribbon 2 inside the high molecular plastic material 5 in the cavity 4 of the injection molding machine, and injecting one piece at a time Preform 1; in the present invention, such as figure 2 As shown, the preform 1 is preferably in the shape of a right-angled trapezoid, and its end face 1-1 on one side is an inclined plane, and the end face 1-1 is inclined by 8° relative to the vertical plane. With such an inclined end face, the After the array is coupled with the planar optical waveguide chip in the planar optical waveguide splitter, the index of return loss is effectively improved;

[0024] b. Cut off the excess optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com