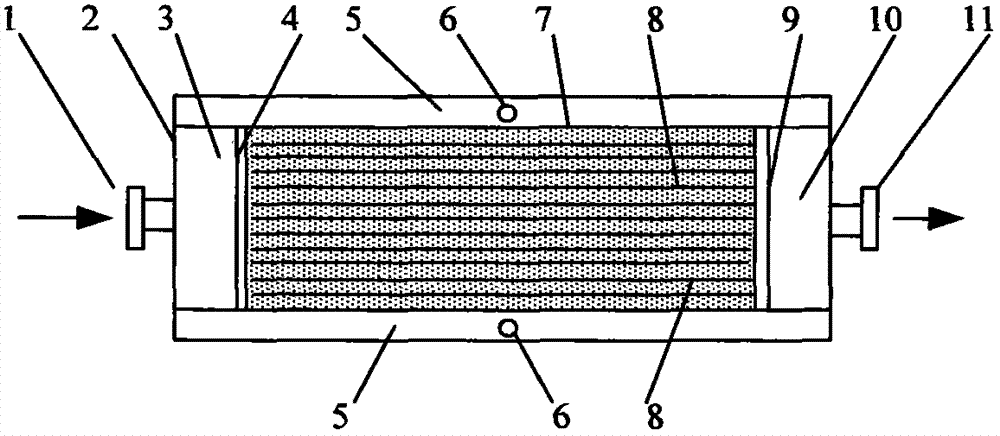

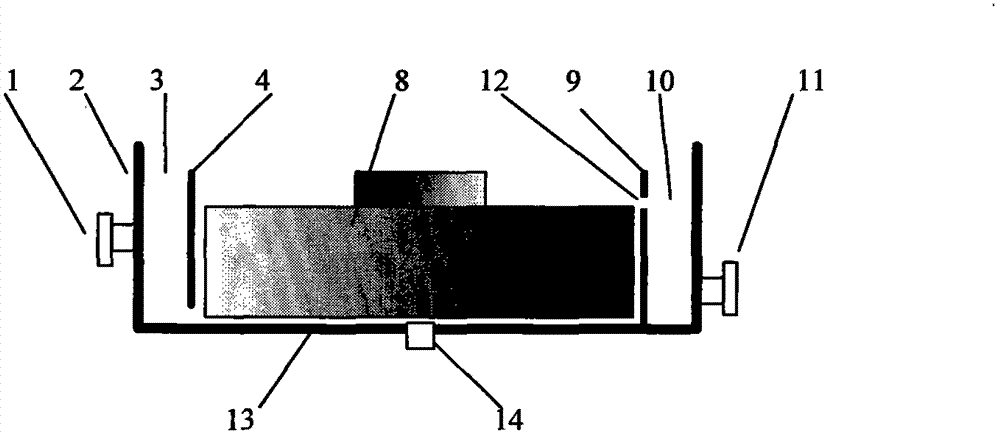

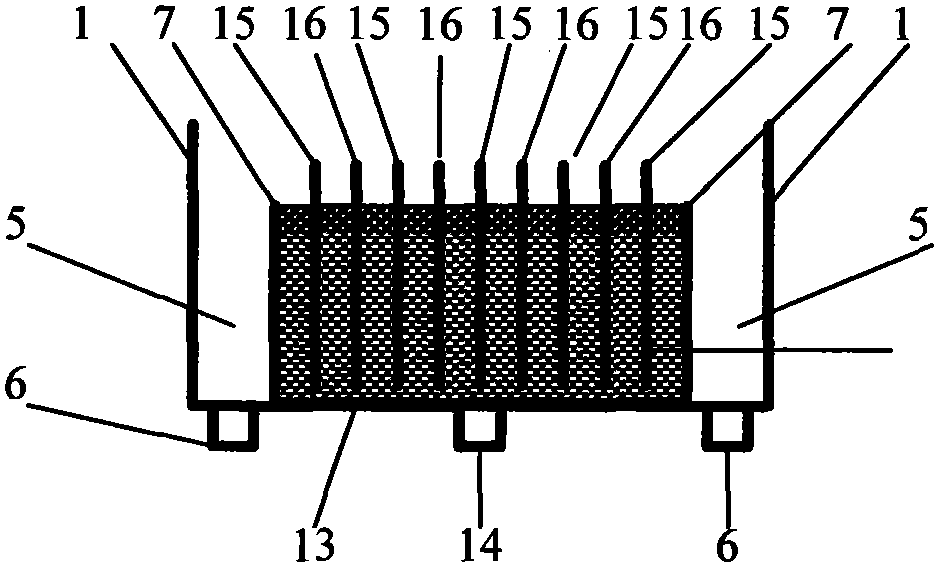

Reaction processor for directly oxidizing residual sludge by using micro-currents

A technology of excess sludge and micro-current, applied in the direction of oxidation treatment of sludge, etc., to achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Experimental equipment: reaction treatment device for direct oxidation of sludge generated by microcurrent 1600×1400×650 (mm), effective volume 0.5L

[0025] DC power supply 20V / 2000A

[0026] Sludge pump N: 0.55kw, Q: 1-5m 3 / h

[0027] Analytical instrument: 10,000-level electronic balance

[0028] infrared oven

[0029] Water circulation vacuum pump

[0030] Sludge source: Changzhou Chengbei Sewage Treatment Plant

[0031] Experimental steps:

[0032] 1. Start the sludge pump and adjust the flow rate to 3m 3 / h, pump the wet sludge into the reactor to the water level of the reactor overflow port, turn off the sludge pump, start the DC power supply, restart the sludge pump, continue to work according to the set flow rate, and take a sample after 10 minutes.

[0033] 3. Adjust the flow meter at the outlet of the sludge pump to adjust the flow to 1.5m 3 / h, sampled after 20 minutes.

[0034] 4. The samples taken are three groups of balanced control sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com