Self-leveling mortar material with phosphogypsum as filling material, and preparation method thereof

A technology for self-leveling mortar and phosphogypsum, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as the inability to meet the demand of phosphogypsum, and achieve the advantages of simple process, cost saving and energy consumption reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

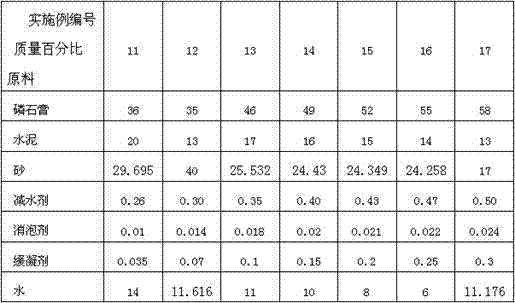

Examples

Embodiment 1

[0028] A self-leveling mortar material with phosphogypsum as filler, the raw material components and mass percentage composition include: 9.6% of rapid hardening 42.5 sulfoaluminate cement, 6% of 42.5 Portland cement, 38% of phosphogypsum, 30-50 mesh Quartz sand 16.6%, 40-70 mesh quartz sand 16.6%, polycarboxylate water reducer, defoamer, borax 0.36%, 0.02%, 0.07%, water consumption 12.75%.

[0029] Results: The initial fluidity was 144mm, the 20-minute fluidity was 137mm, the 1-day compressive strength and flexural strength were 8MPa and 2.7MPa respectively, and the 28-day compressive strength and flexural strength were 24.4MPa and 7.6MPa respectively. The strength is 1.8MPa, the wear amount is 0.27g, and the dimensional change rate in 28 days is -0.05%.

Embodiment 2

[0031] A self-leveling mortar material with phosphogypsum as a filler, the raw material components and mass percentages include: rapid hardening 42.5 sulfoaluminate cement 10%, 42.5 Portland cement 6%, phosphogypsum 41%, 30-50 mesh Quartz sand 15%, 40-70 mesh quartz sand 15%, polycarboxylate superplasticizer, defoamer, borax 0.35%, 0.02%, 0.07%, water consumption 12.56%.

[0032] Results: The initial fluidity was 138mm, the fluidity in 20 minutes was 138mm, the 1-day compressive strength and flexural strength were 9.5MPa and 3.0MPa respectively, and the 28-day compressive strength and flexural strength were 26.3MPa and 8.6MPa respectively. The joint strength is 1.6MPa, the wear amount is 0.31g, and the dimensional change rate in 28 days is -0.07%.

Embodiment 3

[0034] A self-leveling mortar material with phosphogypsum as filler, the raw material components and mass percentage composition include: 9.7% of rapid hardening 42.5 sulfoaluminate cement, 6% of 42.5 Portland cement, 46.7% of phosphogypsum, 30-50 mesh Quartz sand 12.3%, 40-70 mesh quartz sand 12.3%, polycarboxylate water reducer, defoamer, borax 0.35%, 0.02%, 0.07%, water consumption 12.56%.

[0035] Results: The initial fluidity was 143mm, the 20-minute fluidity was 142mm, the 1-day compressive strength and flexural strength were 8.8MPa and 2.8MPa respectively, and the 28-day compressive strength and flexural strength were 26.5MPa and 9.2MPa respectively. The joint strength is 1.6MPa, the wear amount is 0.36g, and the dimensional change rate in 28 days is -0.11%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com