Method for preparing degradable dry beancurd preservation packaging film

A technology of fresh-keeping packaging and dry tofu, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of unsatisfactory strength of soybean protein film and poor moisture resistance of simple polysaccharide film, achieve excellent bacteriostatic performance and reduce the total number of colonies , The effect of emulsion stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

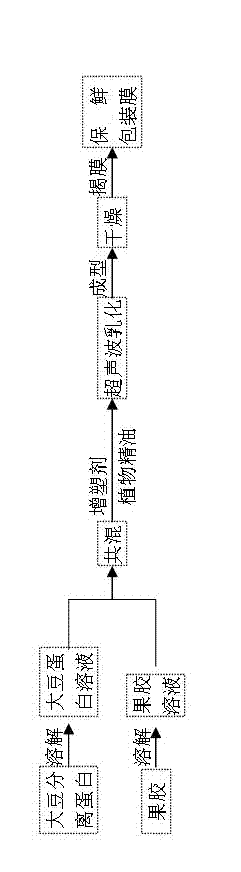

[0032] like figure 1 Shown:

[0033] (1) In parts by weight, weigh 2 parts of soybean protein isolate and add them to 98 parts of deionized water preheated to 50°C, adjust the pH value of the solution to 8 with 2mol / L NaOH solution, and stir at 20r / min for 20 minutes to dissolve the soybeans. Protein isolate is completely dissolved;

[0034] (2) In parts by weight, weigh 1 part of orange peel high-fat pectin and add it to 99 parts of deionized water preheated to 80°C, and stir at 100r / min for 60min until the pectin is completely dispersed;

[0035] (3) Mix soybean protein solution and pectin solution at a volume ratio of 1:0.1 to obtain soybean protein pectin mixed solution, add glycerin accounting for 1% of the mass of soybean protein pectin mixed solution, and then add soybean protein pectin to mix The volume of the solution is 0.1% cinnamon oil, emulsified with a probe-type ultrasonic equipment, the power is 200W, the temperature is controlled at 20°C, and the intermitten...

Embodiment 2

[0039] (1) In parts by weight, weigh 4 parts of soybean protein isolate and add them to 96 parts of deionized water preheated to 60°C, adjust the pH value of the solution to 9 with 2mol / L KOH solution, and stir at 30r / min for 30 minutes until the soybean Protein isolate is completely dissolved;

[0040] (2) In parts by weight, weigh 2 parts of apple peel low-fat pectin, add it to 98 parts of deionized water preheated to 90°C, stir at 150r / min for 70min until the pectin is completely dispersed;

[0041] (3) Mix soybean protein solution and pectin solution at a volume ratio of 1:0.5 to obtain soybean protein pectin mixed solution, add glycerin accounting for 1.5% of the mass of soybean protein pectin mixed solution, and then add soybean protein pectin to mix Solution volume 0.15% mixed oil, the mixed oil is a mixture of cinnamon oil and clove oil with a volume ratio of 1:1, emulsified with a probe type ultrasonic equipment, the power is 300W, the temperature is controlled at 25°...

Embodiment 3

[0045] (1) In parts by weight, weigh 5 parts of soybean protein isolate and add them to 95 parts of deionized water preheated to 55°C, adjust the pH value of the solution to 10 with 2mol / L NaOH solution, and stir at 30r / min for 30 minutes to dissolve the soybeans. Protein isolate is completely dissolved;

[0046] (2) In parts by weight, weigh 3 parts of soybean hull pectin, add it to 97 parts of deionized water preheated to 85°C, and stir at 200r / min for 80min until the pectin is completely dispersed;

[0047](3) Mix soybean protein solution and pectin solution at a volume ratio of 1:0.2 to obtain soybean protein pectin mixed solution, add sorbitol accounting for 1.8% of the mass of soybean protein pectin mixed solution, and then add soybean protein pectin The volume ratio of the mixed solution is 1.5% mixed oil. The mixed oil is a mixture of cinnamon oil, clove oil and oregano oil with a volume ratio of 1:1:1. It is emulsified with a probe-type ultrasonic device with a power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com