Preparation process of adhesive suitable for adhesive coated copper foil

A preparation process and adhesive technology, applied in the direction of adhesives, adhesive types, novolac epoxy resin adhesives, etc., can solve the problems of poor solubility of epoxy resin and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

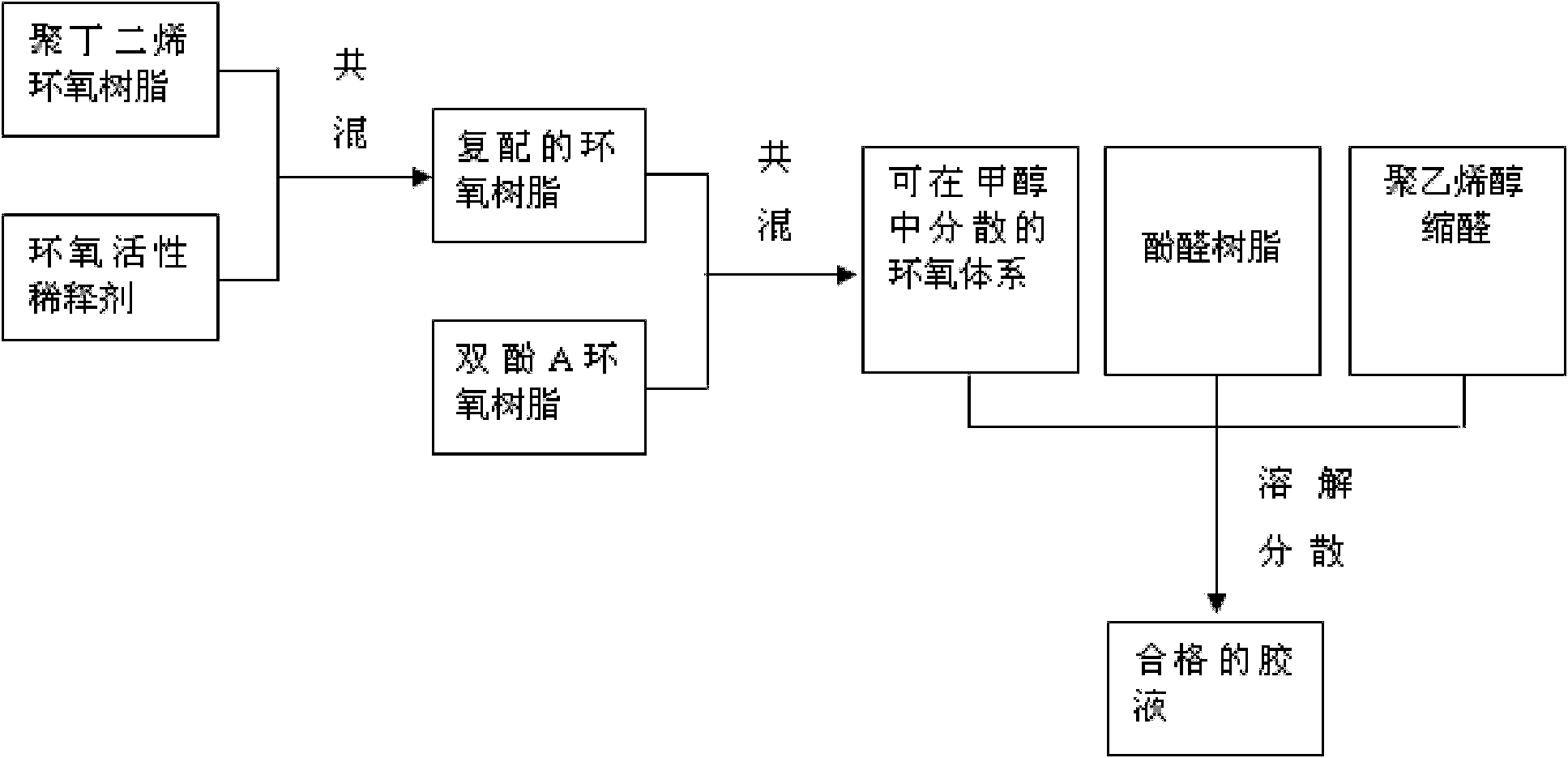

[0007] Such as figure 1 Shown:

[0008] 1. Blend 30-70 parts of polybutadiene epoxy resin (parts by mass) and 2-10 parts of epoxy reactive diluent at 30-70°C for 1-3 hours for compounding;

[0009] 2. Blend the above compound with 5 to 20 parts of bisphenol A epoxy resin at 30 to 70 ° C for 1 to 3 hours to prepare an epoxy dispersion that can be dispersed in methanol;

[0010] 3. Blend the above epoxy dispersion with 400-600 parts of phenolic resin and 500-700 parts of polyvinyl acetal resin at 30-70°C for 5-12 hours for compounding, and use 1125-1750 parts of methanol as a solvent for dispersion , to obtain a qualified copper foil adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com