Process for recovering silver and lead sulfate from slag

A lead sulfate and process technology, applied in the direction of improving process efficiency, can solve the problems of waste of resources, low service life of anode plates, increased energy consumption, etc., to meet the needs and realize the effect of productization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

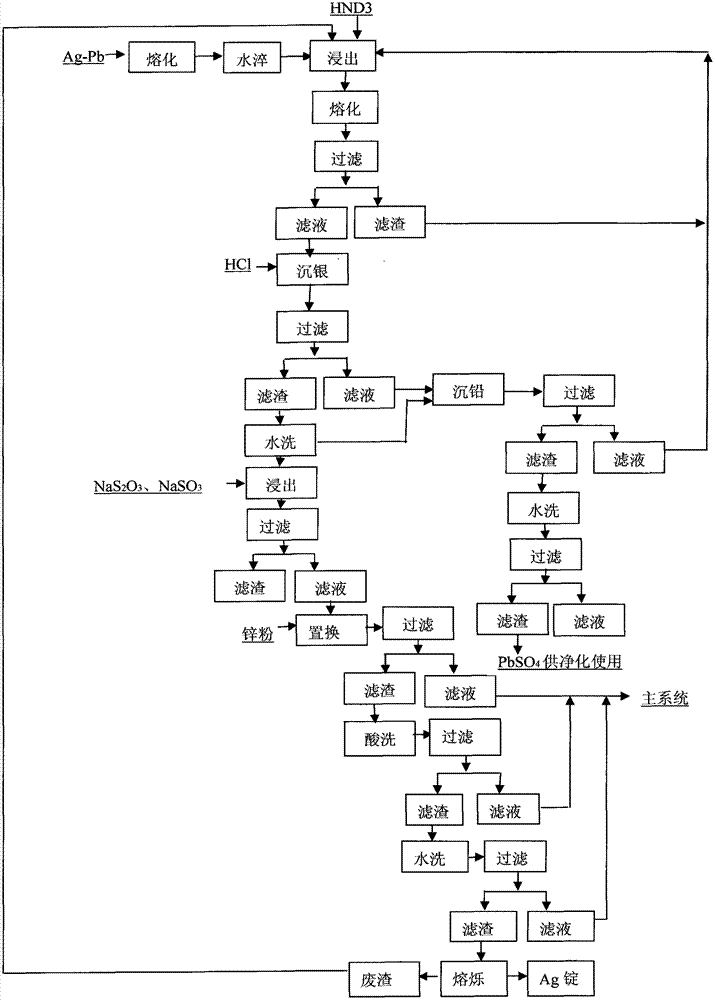

Image

Examples

Embodiment 1

[0054] A kind of technology that utilizes the slag of making anode plate to recover silver and lead sulfate, its concrete steps comprise:

[0055] 1) Nitric acid leaching: Pump the liquid after preparing lead sinking into the leaching tank for about 8-10m 3 After starting the stirring, the amount of slag added to each tank is about 700-800kg, and a certain amount of nitric acid is added. After reacting at a temperature of 70-80°C for 10-12h, the end point pH=3.5-4. filter, the filter residue is returned to the filter press to continue leaching, and the liquid is poured into the immersion silver reaction tank for immersion silver. The principle of nitric acid leaching is as follows:

[0056] 3Ag+4HNO 3 (dilute) = 3Ag NO 3 +NO↑+2H 2 o

[0057] 3Pb+8HNO 3 (dilute)=3Pb(NO 3 ) 2 +2NO↑+4H 2 o

[0058] 2) Immersion silver: add dilute hydrochloric acid to the nitric acid leaching solution, and the amount of hydrochloric acid added is 1.5 times the theoretical amount, so that si...

Embodiment 2

[0074] A process for recovering silver and lead sulfate from slag for making anode plates, the process steps specifically comprising:

[0075] 1) nitric acid leaching,

[0076] Leaching conditions: temperature 75°C, liquid-solid ratio 11:1, reaction time 11 hours, end point PH=4.0, 760kg of slag per tank;

[0077] 2) Immersion silver: adding dilute hydrochloric acid to the nitric acid leaching solution to precipitate silver ions in the form of silver chloride;

[0078] Immersion silver conditions: Add 1.2 times the theoretical amount of hydrochloric acid at the temperature of the reaction solution, and after 0.5 hours of reaction, heat the reaction solution to above 95°C and filter the silver chloride particles;

[0079] 3) lead sinking: add sulfuric acid to the solution after sinking silver, and lead is precipitated in the form of lead sulfate;

[0080] Lead sinking conditions: at natural temperature, add continuous sulfuric acid until satisfactory white precipitate is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com