Preparation method of coated article and coated article prepared by it

A technology of sputtering method and glass base material, which is applied in the preparation of coated parts and the field of coated parts made from it, can solve the problems of limited color of the film layer, etc., and achieve the effect of improving appearance competitiveness, simple process and rich colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

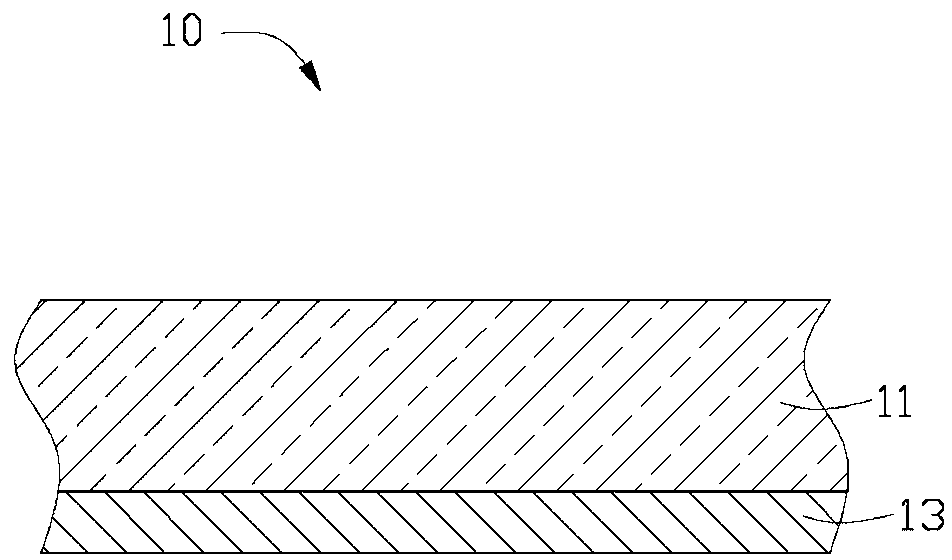

[0018] A coating member 10 of a preferred embodiment of the present invention (such as figure 1 Shown) the preparation method comprises the steps:

[0019] A substrate 11 is provided, and the substrate 11 is transparent glass.

[0020] The surface of the substrate 11 is pretreated. The pretreatment step includes: conventional degreasing and wax removal, and then spraying the substrate 11 with deionized water, and drying the substrate 11 for future use after spraying.

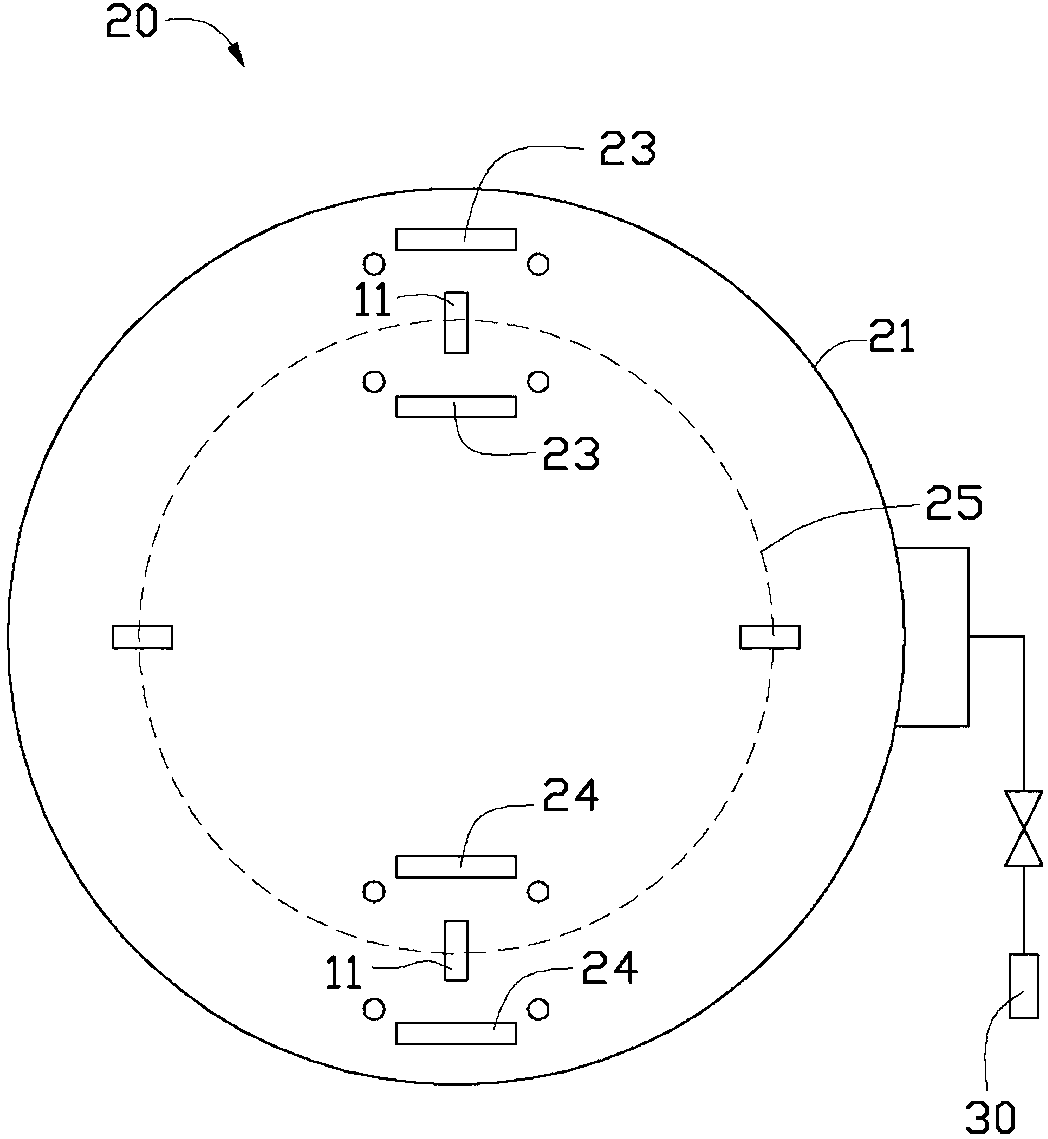

[0021] combined reference figure 2 , provide a vacuum coating machine 20, the vacuum coating machine 20 includes a coating chamber 21 and a vacuum pump 30 connected to the coating chamber 21, the vacuum pump 30 is used to evacuate the coating chamber 21. The coating chamber 21 is provided with a turntable (not shown), two tin targets 23 opposite to each other and two aluminum targets 24 opposite to each other. The turntable drives the base material 11 to revolve along the circular track 25 , and the base ma...

Embodiment 1

[0031] The vacuum coating machine 20 used in this embodiment is a magnetron sputtering coating machine.

[0032] Metal tin deposition: the temperature of the substrate 11 is 230° C., the flow rate of argon gas is 100 sccm; the power of the tin target 23 is 11 kW, the bias voltage applied to the substrate 11 is -30 V, and the deposition time is 20 minutes.

[0033] Metal tin is thermally oxidized to form tin oxide: the oxygen flow rate is 500 sccm, the temperature of the substrate 11 is 230° C., and the treatment time is 20 min.

[0034] Aluminum oxide deposition: the temperature of the substrate 11 is 120°C, the flow rate of argon gas is 100 sccm; the flow rate of oxygen gas is 50 sccm, the power of the aluminum target 24 is 5kW, the bias voltage applied to the substrate 11 is -50V, and the deposition time is 40min .

[0035] In this embodiment, the thickness of the color layer 13 is 500nm. The result of testing the color difference of the color layer 13 through the base mat...

Embodiment 2

[0037] Metal tin deposition: the temperature of the substrate 11 is 300° C., the flow rate of argon gas is 500 sccm; the power of the tin target 23 is 5 kW, the bias voltage applied to the substrate 11 is -50 V, and the deposition time is 5 minutes.

[0038] Metal tin is thermally oxidized to form tin oxide: the oxygen flow rate is 100 sccm, the temperature of the substrate 11 is 250° C., and the treatment time is 10 min.

[0039] Aluminum oxide deposition: the temperature of the substrate 11 is 180° C., the flow rate of argon is 500 sccm; the flow rate of oxygen is 100 sccm, the power of the aluminum target 24 is 11 kW, the bias voltage applied to the substrate 11 is -100 V, and the deposition time is 20 min .

[0040] In this embodiment, the thickness of the color layer 13 is 680nm. The result of testing the color difference of the color layer 13 through the substrate 11 is: the L* coordinate is 88, the a* coordinate is 0.1, and the b* coordinate is -0.4.

[0041] In the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com