Cam shaft with encoding disk and lubricating oil channel

A technology for lubricating oil passages and camshafts, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of many transmission parts, large mass, and increase in the peripheral size of the engine, and achieves reduced peripheral size and convenient assembly and layout. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

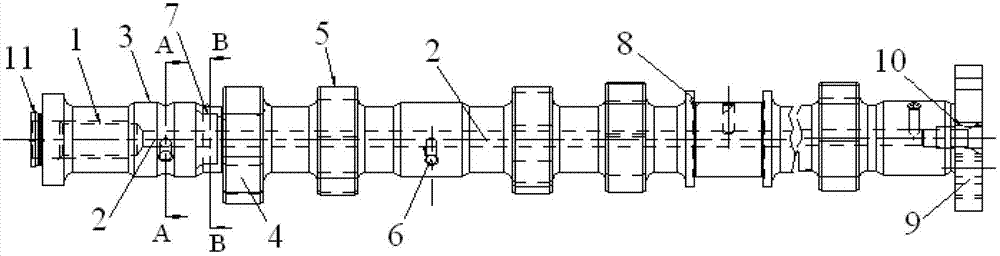

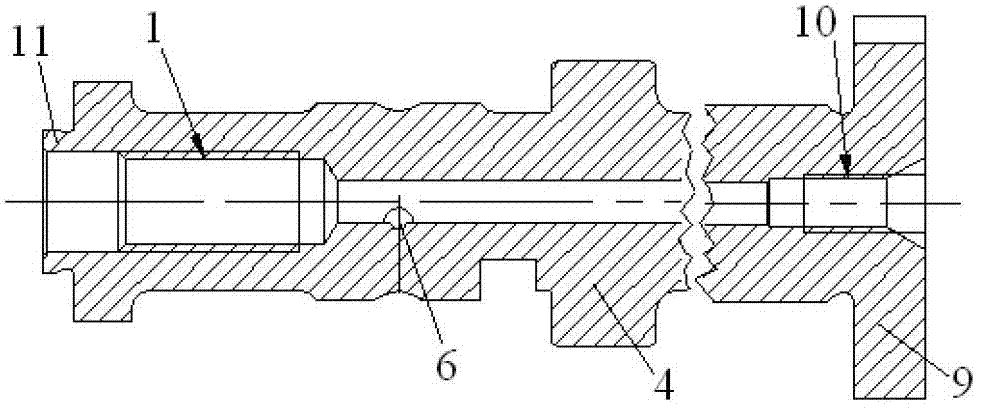

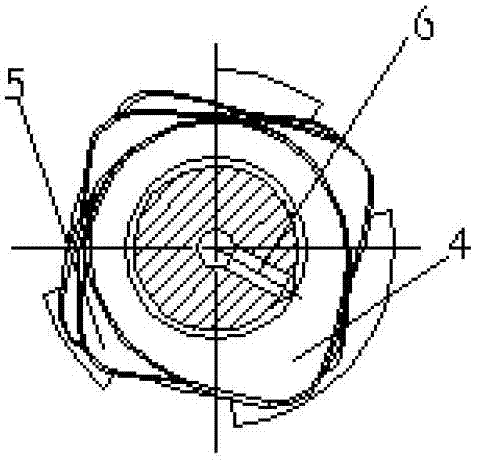

[0014] The structure and principle of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments. Camshaft with code disc and lubricating oil channel, its structure is that the camshaft is a hollow shaft, an internal thread section 1 is arranged in the shaft center of the leftmost end of the camshaft, and the shaft at the end of the camshaft is behind the internal thread section The center is used as lubricating oil passage 2, and the camshaft is provided with supporting journal section 3, intake cam 4 and exhaust cam 5 in sequence (such as figure 1 , figure 2 ). Each bearing journal section is provided with oil inlet and outlet ports 6 (such as image 3 ), there is a timing plane 7 between the first bearing journal section at the left end of the camshaft and the intake cam (such as Figure 4 ), an axial thrust surface 8 is provided behind the second exhaust cam from the left of the camshaft, a gas d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com