Laser ultrasonic detection device

A laser ultrasonic and detection device technology, which is applied in measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, and material analysis through optical means, can solve problems such as poor detection accuracy, and achieve fast scanning speed and practicality Strong, high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

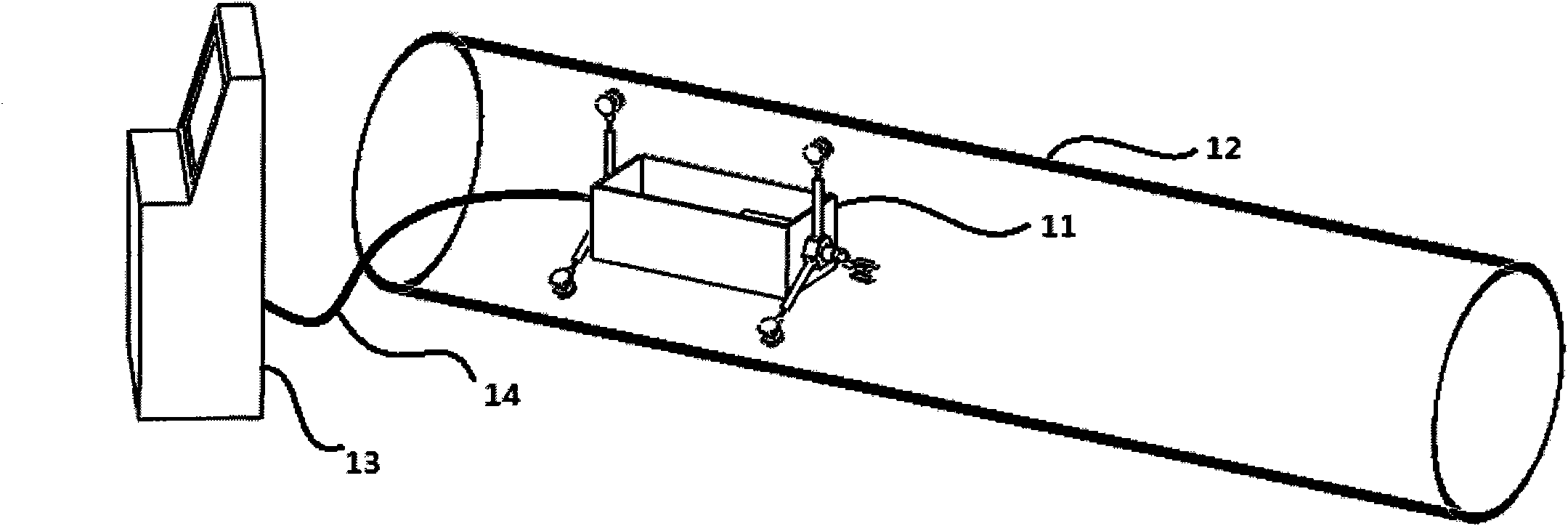

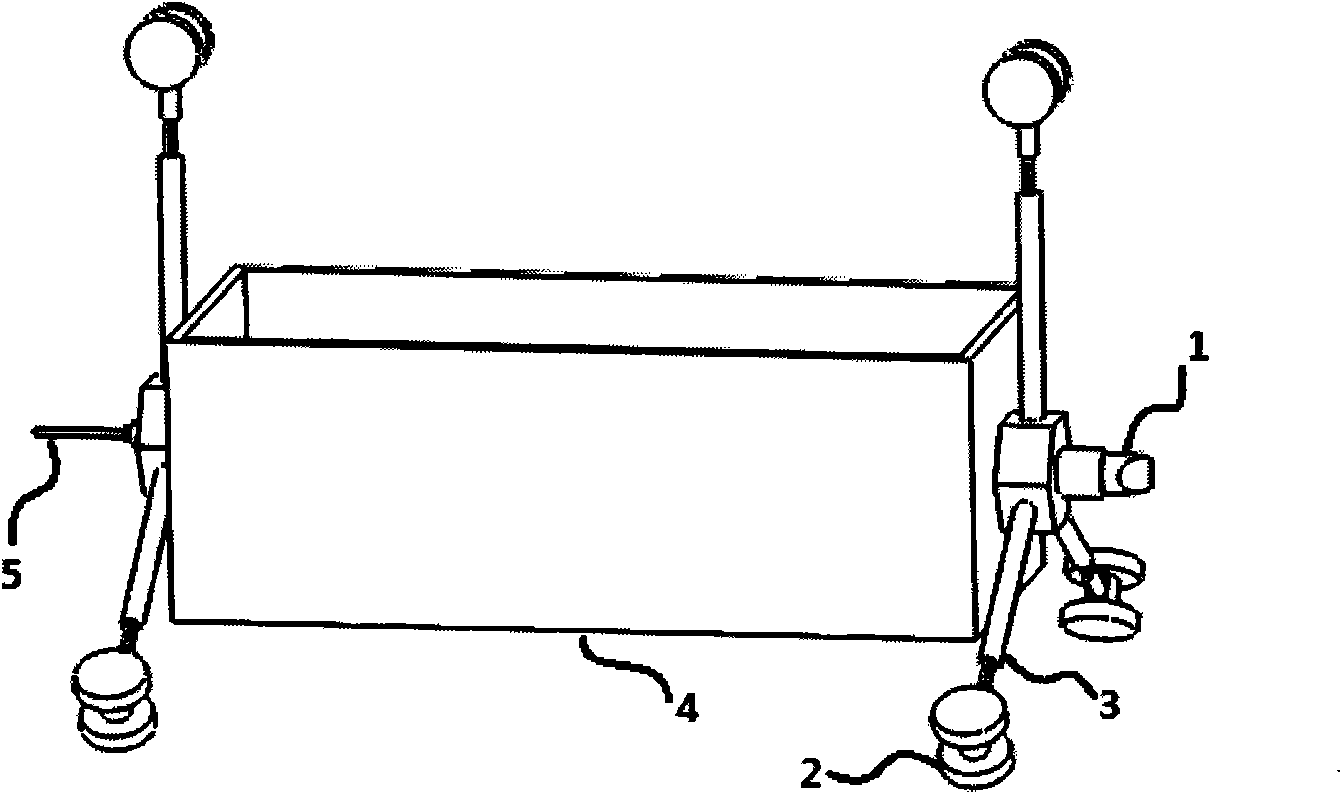

[0024] According to the instructions, make a set of laser ultrasonic detection device of the present invention, which device includes crawling car 11, optical fiber 14, external console 13, such as figure 1 shown. The external console 13 includes laser ultrasonic excitation source, control system circuit, control system software, display and other components. The crawling trolley 11 includes 6 sets of rotating scanning head 1, roller 2 and telescopic pole 3, a box body 4, and a communication optical interface 5, such as figure 2 shown. Wherein there are 6 sets of rollers 2 and telescopic poles 3, which are divided into two groups and fixed on both sides of the crawling trolley 11, with 3 sets in each group. The crawling trolley 11 is also equipped with a storage battery as a power source to provide power for the crawling trolley 11 . The crawling car 11 and the external console 13 exchange data through the optical fiber 14, and the exchanged data includes controlling the r...

Embodiment 2

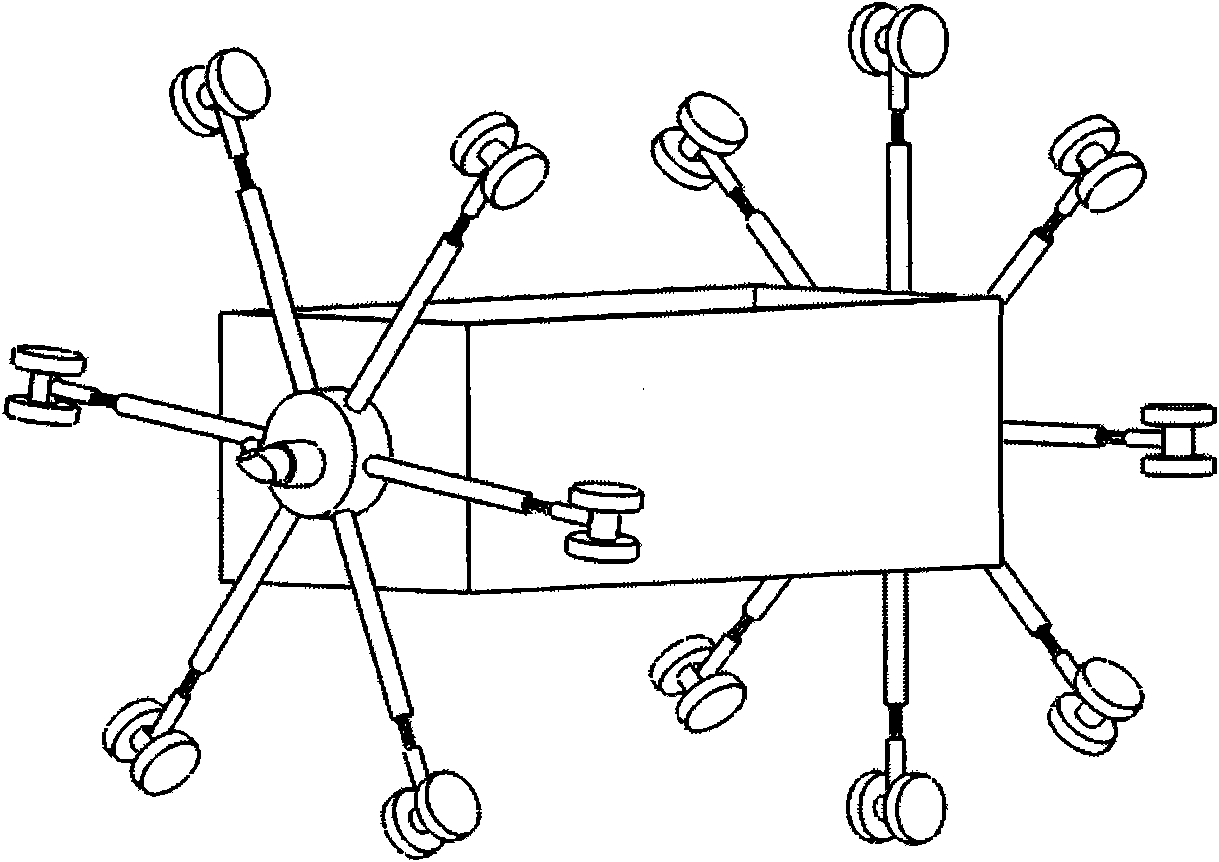

[0027] According to the instructions, a set of laser ultrasonic testing device of the present invention is made, which includes a crawling trolley 11, an optical fiber 14, and an external console 13. Wherein the external console 13 includes control system circuit, control system software, display and other components. The crawling trolley 11 includes a rotating scanning head 1, a total of 14 rollers 2 and telescopic poles 3, a box body 4, and a communication light interface 5, such as image 3 shown. Among them, there are 14 sets of rollers 2 and telescopic poles 3, which are divided into two groups and fixed on both sides of the crawling trolley 11. There are 6 sets on one side of the rotating scanning head 1 and 8 sets on the other side. The lengths of these telescopic poles are different. Can adjust the length, suitable for round, oval and rectangular pipes. The crawling trolley 11 is also equipped with a laser ultrasonic excitation source and a storage battery as a power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com