Method for preparing water-soluble plant melanin

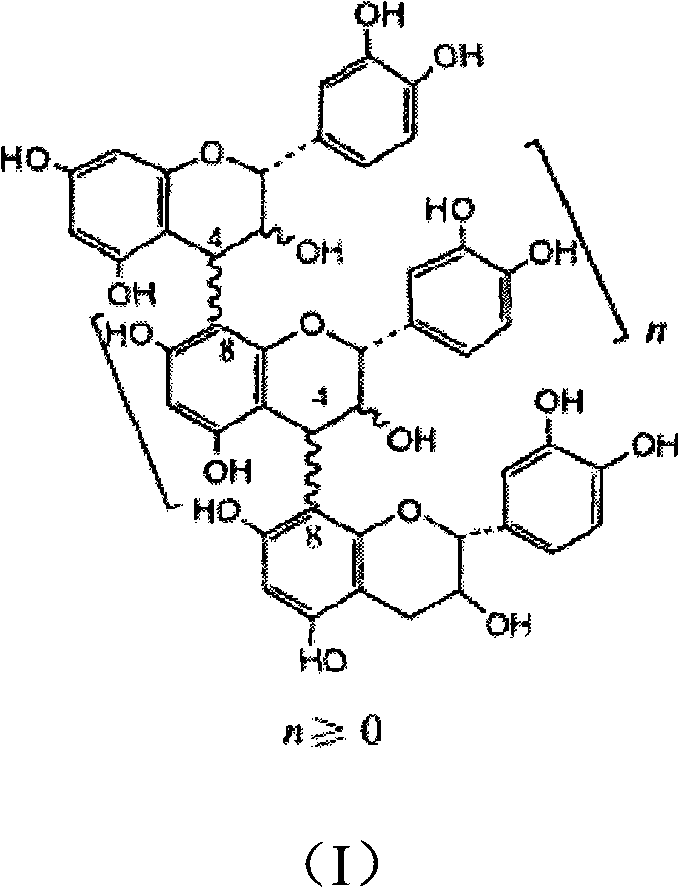

A manufacturing method and melanin technology, applied in the field of plant melanin manufacturing, can solve the problems of impossible water solubility, destroying the three-dimensional structure of melanin, unable to restore water solubility of melanin, etc., and achieving the effect of excellent water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Get 1kg of fresh black rice leaves, mash it with a tissue masher, and prevent the local temperature from exceeding 60°C during the mash process. Transfer to a reaction kettle, add 2L of 60% (v / v) ethanol aqueous solution, extract at a temperature of about 50°C for 2.5 hours, filter off the residue to obtain a filtrate, remove ethanol under reduced pressure until there is no alcohol smell, and the obtained concentrated The liquid was supplemented with deionized water to the initial volume of the filtrate, and passed through the ultrafiltration membrane of AMICON-polysulfone P100 to obtain an aqueous solution of the melanin precursor, and the total phenolic mass in the melanin precursor solution was measured as 24.5g according to GB8313-87.

[0036] 2.45g (i.e. 10wt.%) polyphenol oxidase (the specific activity of this polyphenol oxidase is more than 10000 units / g) is dropped into the melanin precursor solution, under the condition of 37 ℃, insulation reaction 5hr, and with...

Embodiment 2

[0040] Get 1kg of fresh black rice leaves, mash it with a tissue masher, and prevent the local temperature from exceeding 60°C during the mash process. Transfer to a reaction kettle, add 1L of 80% (v / v) acetone aqueous solution, extract at a temperature of about 25°C for 2.5 hours, filter off the residue to obtain a filtrate, remove acetone under reduced pressure until there is no acetone smell, and concentrate the obtained The liquid was supplemented with deionized water to the initial volume of the filtrate, and passed through the ultrafiltration membrane of AMICON-polysulfone P100 to obtain an aqueous solution of the melanin precursor, and the total phenolic mass in the melanin precursor solution was measured as 22.1g according to GB8313-87.

[0041] 4.42g (i.e. 20wt.%) polyphenol oxidase (the specific activity of this polyphenol oxidase is more than 10000 units / g) is dropped into the melanin precursor solution, under the condition of 35 ℃, insulation reaction 3hr, and with ...

Embodiment 3

[0045] Get 1kg of fresh black rice leaves, mash it with a tissue masher, and prevent the local temperature from exceeding 60°C during the mash process. Transfer to a reaction kettle, add 3L of 50% (v / v) acetone aqueous solution, extract at a temperature of about 50°C for 2.5hr, filter off the residue to obtain a filtrate, remove acetone under reduced pressure until there is no acetone smell, and concentrate the obtained The liquid was supplemented with deionized water to the initial volume of the filtrate, and passed through an ultrafiltration membrane of AMICON-polysulfone P100 to obtain an aqueous solution of the melanin precursor, and the mass of total phenols in the melanin precursor solution was measured as 25.0 g according to GB8313-87.

[0046] 25.0g (i.e. 100wt.%) polyphenol oxidase (the specific activity of this polyphenol oxidase is more than 10000 units / g) is dropped into the melanin precursor solution, under the condition of 42 ℃, insulation reaction 2hr, and with 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com