Economical wear-resistant steel and manufacturing method thereof

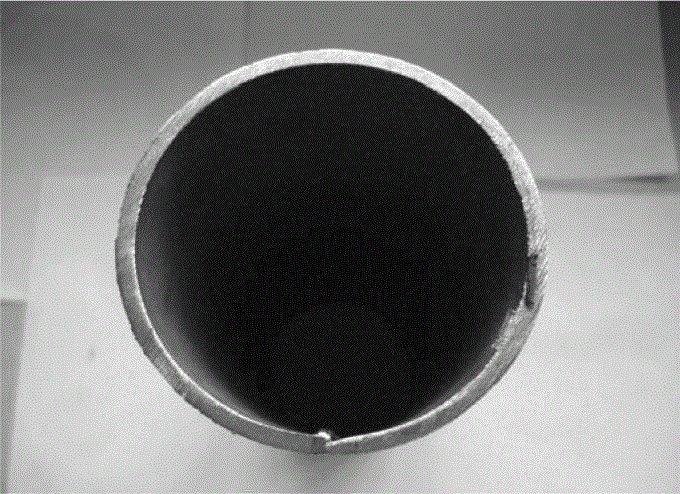

A technology of wear-resistant steel pipe and manufacturing method, which is applied in the field of wear-resistant steel, can solve the problems of troublesome concrete tamping, low wear resistance of boom pipes, frequent replacement, etc., and achieve shortened production process, high hardness, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

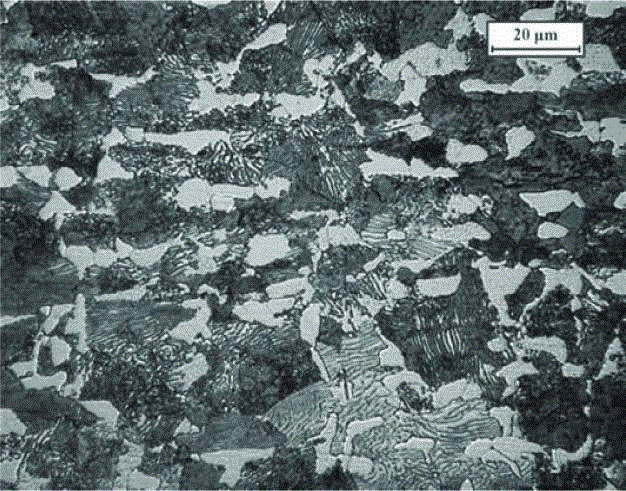

[0054] The chemical composition of the wear-resistant steel pipe of the present invention is shown in Table 1. After smelting according to the chemical composition shown in Table 1, heat the continuous casting slab or steel ingot to 1230°C, the rolling temperature of the first stage is 1010°C, and the reduction ratio is 85%, the rolling temperature of the second stage is 890°C, and the reduction ratio is 76% , the cooling rate is 5.60°C / s, the coiling temperature is 720°C, the quenching temperature is 835°C, the holding time is 15min, the tempering temperature is 130°C, the holding time is 15min, air cooling after tempering.

Embodiment 2

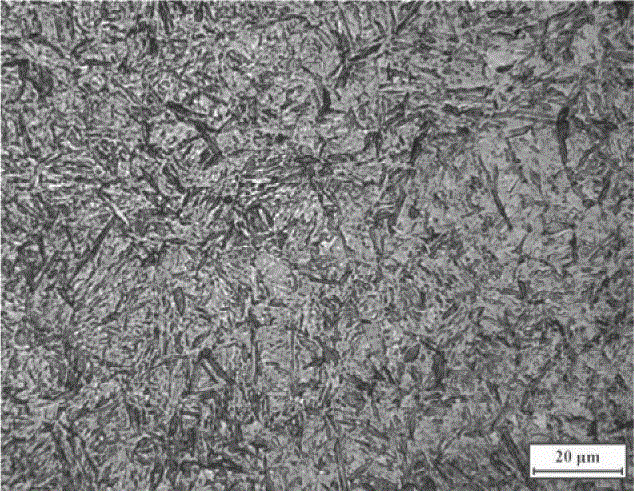

[0056] The implementation is the same as in Example 1, wherein the heating temperature of the continuous casting slab or steel ingot is 1210°C, the rolling temperature of the first stage is 1015°C, and the reduction ratio is 83%, the rolling temperature of the second stage is 840°C, the reduction ratio is 66%, and cooling The speed is 4.0°C / s, the coiling temperature is 708°C, the quenching temperature is 820°C, the holding time is 25min, the tempering temperature is 220°C, the holding time is 20min, air cooling after tempering.

Embodiment 3

[0058] The implementation is the same as in Example 1, wherein the heating temperature of the continuous casting slab or steel ingot is 1160°C, the rolling temperature of the first stage is 1020°C, and the reduction ratio is 85%, the rolling temperature of the second stage is 855°C, the reduction ratio is 75%, and cooling The speed is 9.5°C / s, the coiling temperature is 680°C, the quenching temperature is 880°C, the holding time is 28min, the tempering temperature is 280°C, the holding time is 46min, air cooling after tempering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com