Fuel cell standby power high pressure hydrogen supply system

A fuel cell and backup power supply technology, applied in mechanical equipment, equipment loaded into pressure vessels, container filling methods, etc., can solve problems such as low safety performance, bulky hydrogen storage system, and low hydrogen storage density by weight, so as to avoid Safety accidents, meeting technical requirements, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

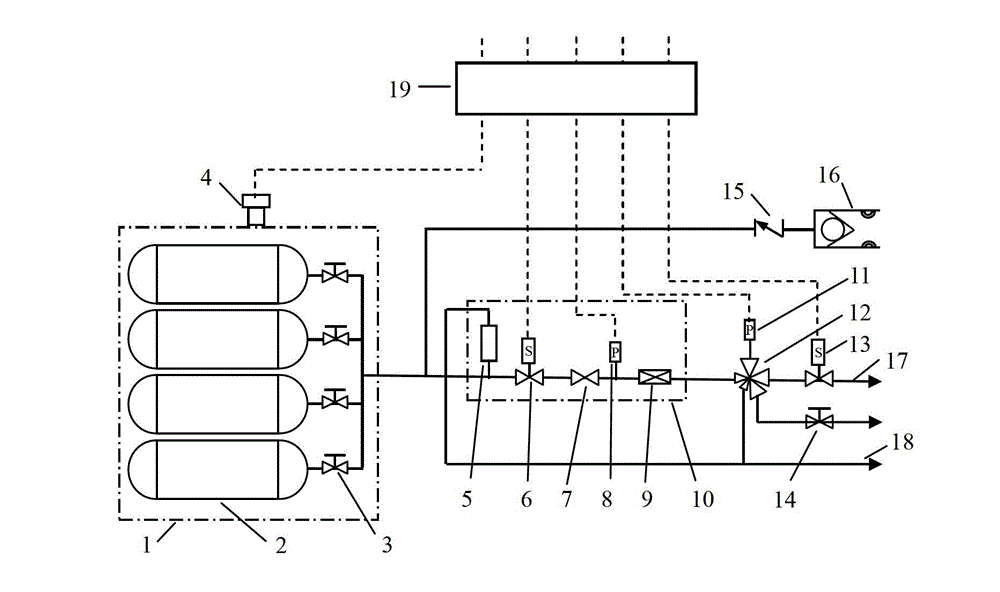

[0025] A high-voltage hydrogen supply system for a fuel cell backup power supply, the system includes an automatic hydrogen supply unit, a hydrogen filling and receiving unit, and a safety control unit, the hydrogen automatic supply unit and the hydrogen filling and receiving unit are connected by pipelines, and the hydrogen filling and receiving unit It is connected with the safety control unit by wire. The hydrogen automatic supply unit includes a high-pressure composite hydrogen storage bottle set 1, an external combination valve 10, a steady-state pressure regulating valve 12, a low-pressure pressure sensor 11, a low-pressure solenoid valve 13 and a gas supply system control module 19;

[0026] The summary outlet of the high-pressure hydrogen storage cylinder group 1 is connected to the air inlet of the external combined valve 10 through a high-pressure pipeline; the exhaust port of the external combined valve 10 is connected to the air inlet of the steady-state pressure re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com