Flexible heat-transfer device based on low-melting metal joints

A low-melting-point metal and joint technology, applied in the direction of indirect heat exchangers, heat exchange equipment, semiconductor devices, etc., can solve the problems of limiting the bending flexibility of flexible pipe sections, large contact thermal resistance, and easy failure of heat pipes, etc., to achieve easy implementation , Small thermal contact resistance, high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

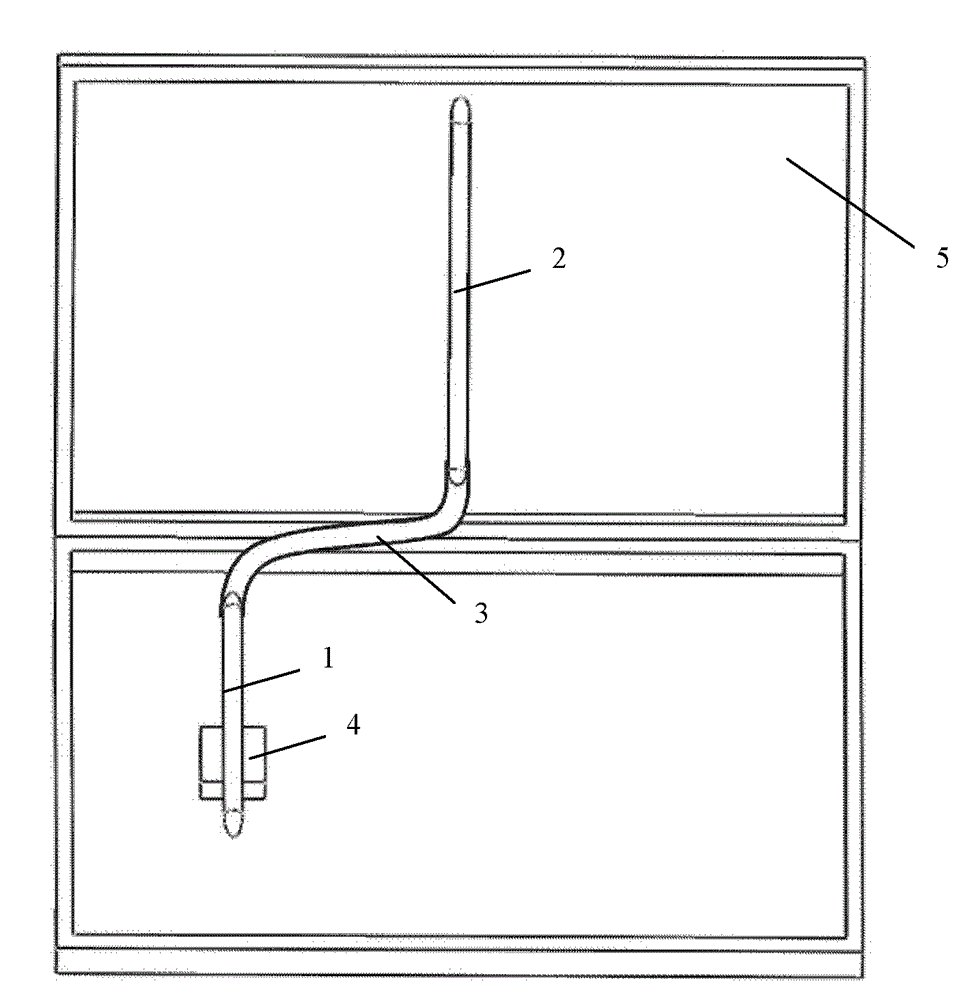

[0022] The flexible heat conduction device based on the low-melting-point metal joint provided by the invention can be used for heat dissipation of electronic devices such as notebook computers and mobile phones. figure 2 It shows the structural representation of the low-melting point metal flexible heat conduction device that conducts the heat from the CPU of the laptop to the LCD backplane for heat dissipation.

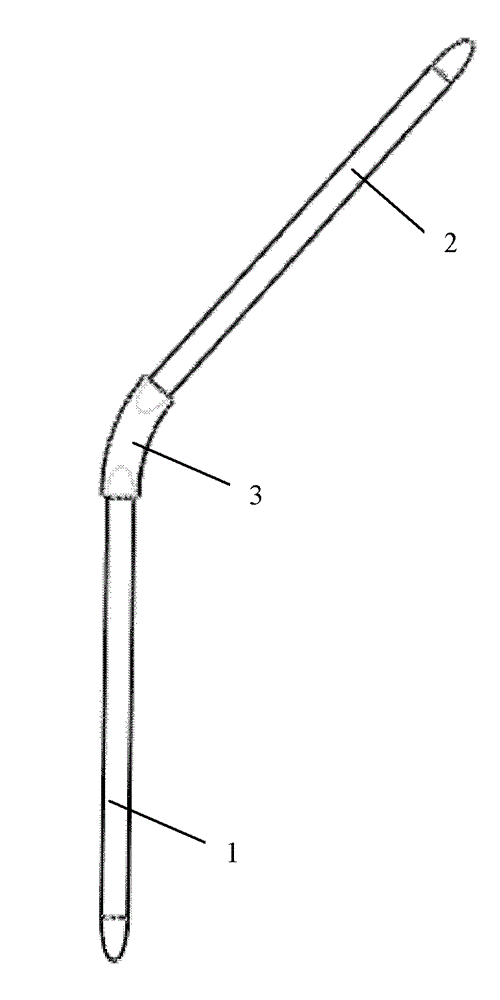

[0023] Depend on figure 1 It can be seen that the flexible heat conduction device based on low-melting-point metal joints of the present invention is composed of N flexible pipe-type liquid metal joints and (N+1) heat pipes; said N is a positive integer of 1 to 10, and said heat pipes It is connected to both ends of the flexible pipe type liquid metal joint; the pipe of the flexible pipe type liquid metal joint stores low melting point metal which is liquid at room temperature.

[0024] figure 1 In the shown embodiment, N=1, that is, the flexible heat conduction ...

Embodiment 2

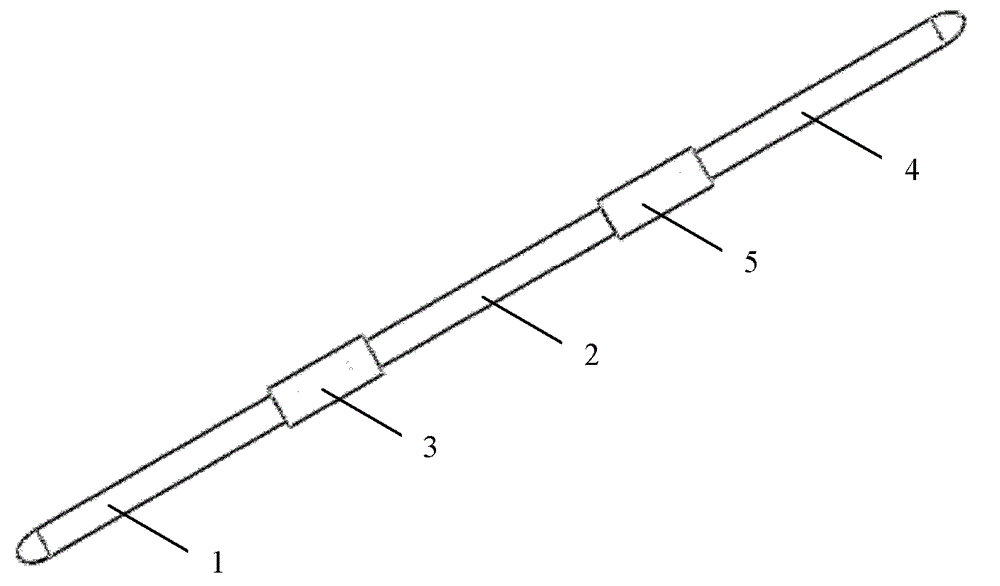

[0032] Such as image 3 As shown, the flexible heat conduction device based on the low-melting point metal joint provided by the present invention can be cascaded sequentially to form a multi-stage flexible heat conduction device with multiple heat pipes and multiple flexible pipeline liquid metal joints; the multi-stage flexible heat conduction device can realize More flexible arrangement and bending.

[0033] N=2 in this embodiment, that is: three heat pipes (the first heat pipe 1, the second heat pipe 2, the third heat pipe 4) and two flexible pipe type liquid metal joints (the first flexible pipe type liquid metal joint 3, the second Flexible pipe type liquid metal joint 5); the first heat pipe 1, the first flexible pipe type liquid metal joint 3, the second heat pipe 2, the second flexible pipe type liquid metal joint 5 and the third heat pipe 4 are sequentially connected to form a three-stage type Flexible heat conduction device.

[0034] Both the pipes of the first fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com