Bottom valve and piston valve assembly line as well as bottom valve and piston valve assembly error identification method

A piston valve and assembly line technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting product quality and low labor efficiency, and achieve the effect of improving labor productivity, saving labor, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

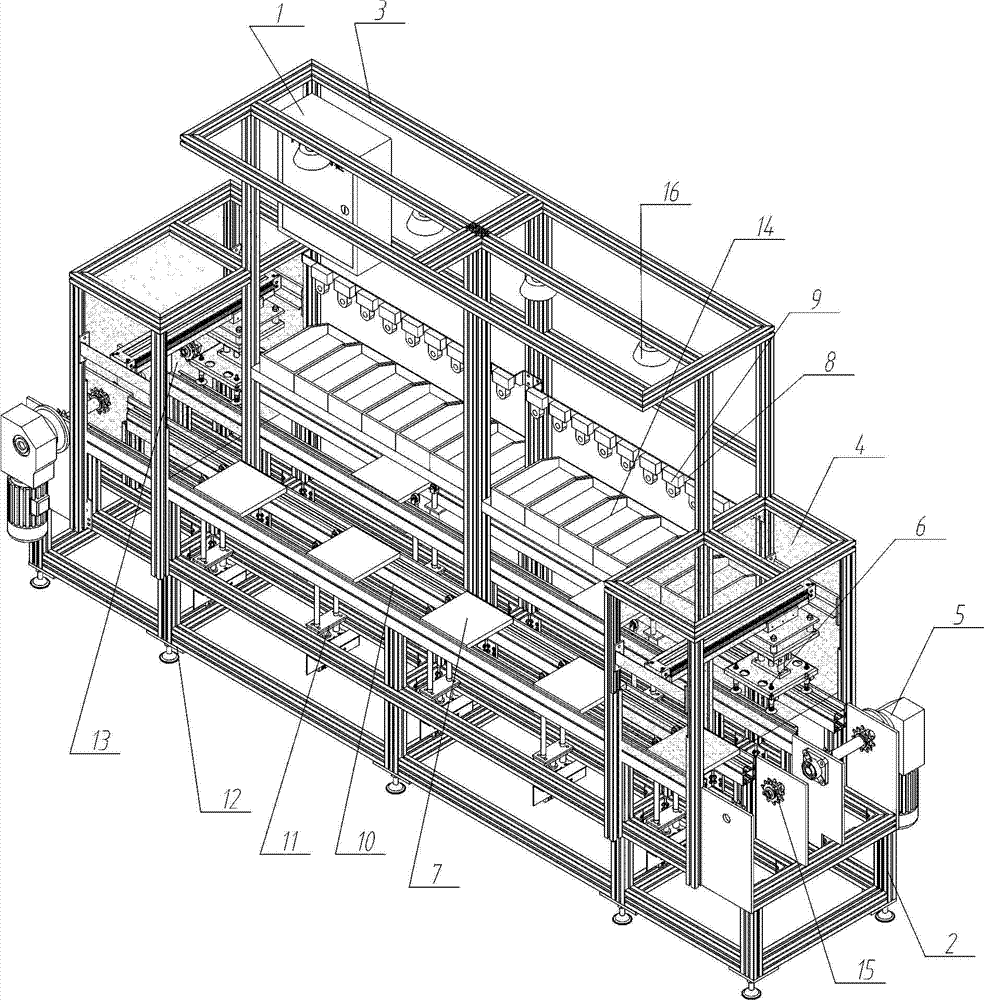

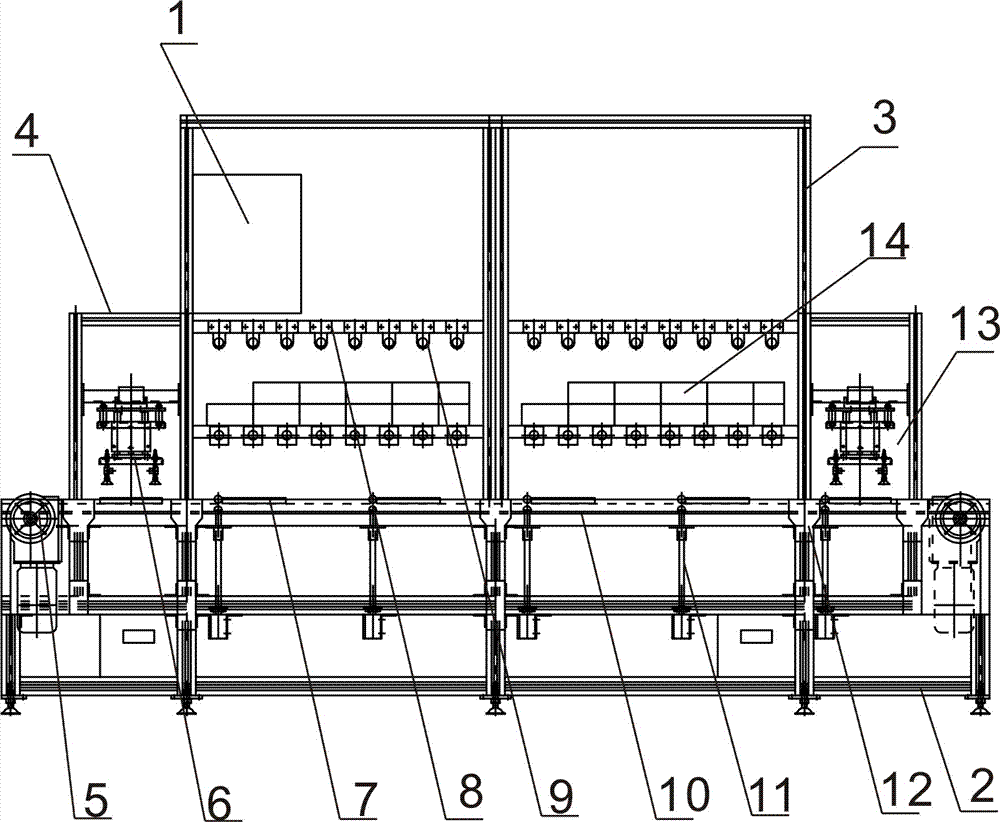

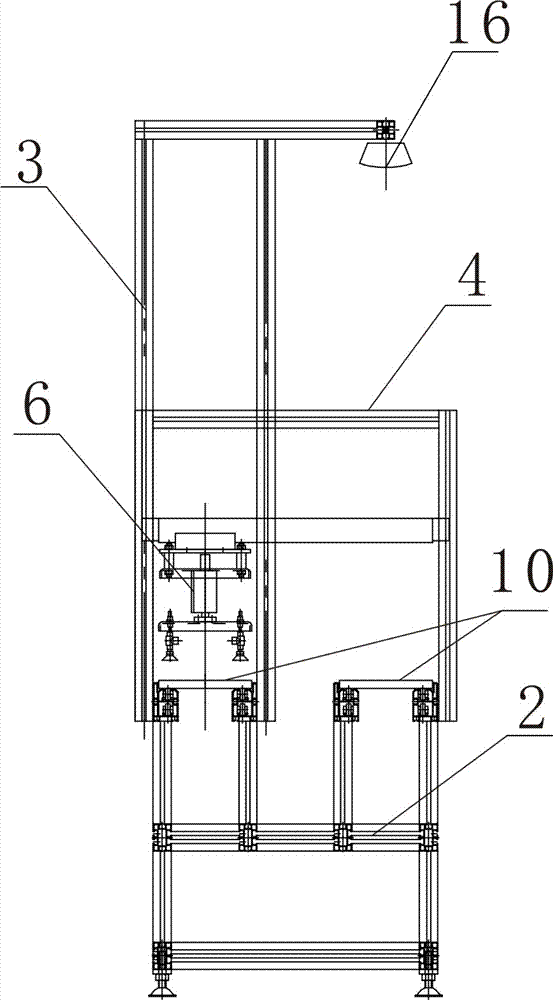

[0020] As shown in 1-3: a bottom valve and piston valve assembly line includes PLC control cabinet 1, frame 2, shadowless lamp lamp frame 3, dust cover 4, and two conveyor lines with opposite conveying directions and parallel installation on the frame 10. Tooling plate 7 , transfer device 6 and drive unit 5 for transferring the tooling plate. The two rows of conveyor lines 10, one row is the conveyor line that transports the tooling board from the initial station to the finished product off-line, and the other row is the conveyor line that returns the tooling board after the finished product is off-line to the initial station.

[0021] The transfer device 6 can be a manipulator, or a transfer device made of a slider cylinder, a lifting cylinder, a hollow generator and a vacuum suction cup. The transfer device 6 is installed in two groups at b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com