Graphene-based hydrogel and preparation method thereof as well as preparation method and application of supercapacitor electrode taking graphene-based hydrogel as active material

A supercapacitor, graphene-based technology, applied in the direction of capacitors, graphene, electrolytic capacitors, etc., can solve the problem of reducing agent toxicity, complexity, etc., and achieve the effect of improving high rate performance, high effective area, and large aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

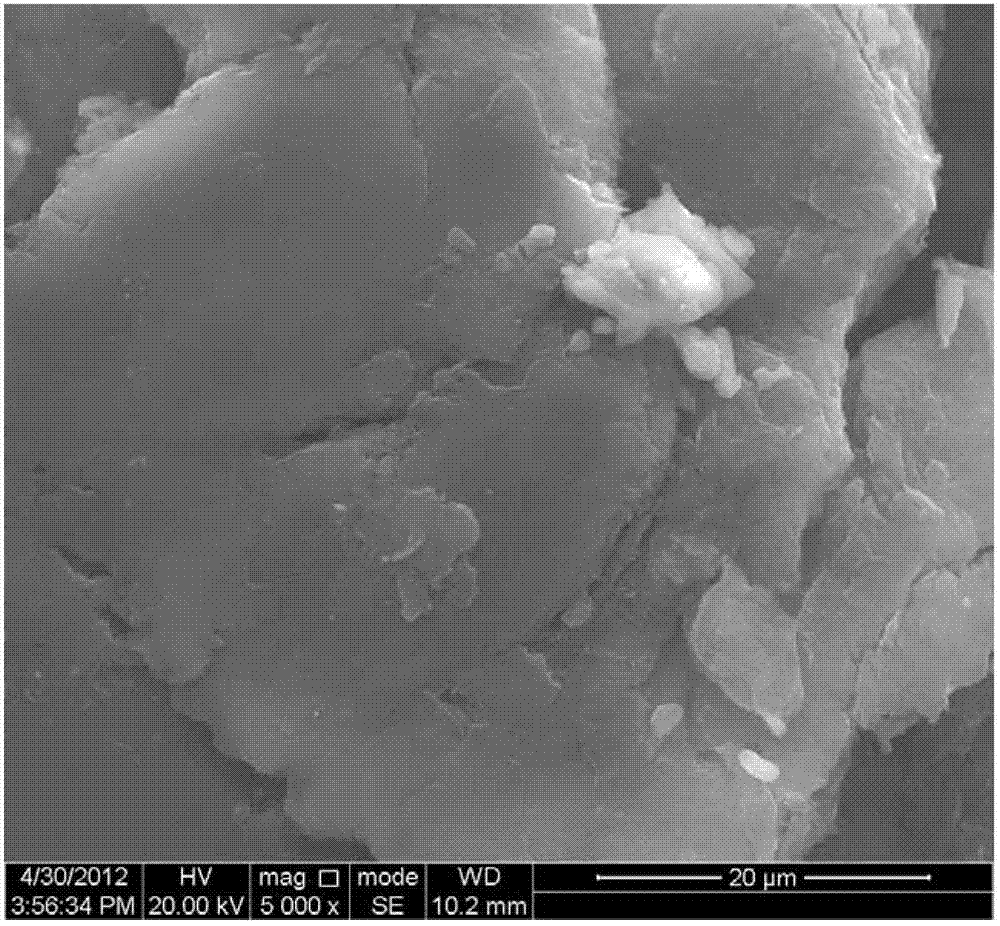

[0035] Embodiment 1: The graphene-based hydrogel of this embodiment is a hydrogel formed of graphene, and the water in the hydrogel accounts for 90% to 99.5% of the total mass.

specific Embodiment approach 2

[0036] Embodiment 2: This embodiment differs from Embodiment 1 in that the water in the hydrogel accounts for 93% to 99% of the total mass. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the preparation method of the graphene-based hydrogel described in specific embodiment one is carried out according to the following steps:

[0038] 1. Weigh graphite and reducing agent; wherein the mass ratio of graphite and reducing agent is 1: (1-1000); the reducing agent is one or a combination of KOH, NaOH, LiOH and ammonia water; when reducing agent When it is a composition, each reducing agent is combined in any ratio;

[0039] Two, the graphite oxidation that takes by step one becomes graphite oxide;

[0040] 3. According to the concentration of graphite oxide being 0.01mg / mL~50mg / mL, add the graphite oxide obtained in step 2 into water, ultrasonically peel and disperse to obtain a graphene oxide water dispersion;

[0041] 4. Add a reducing agent to the graphene oxide aqueous dispersion obtained in step 3 at a temperature of 4°C to 100°C, and reduce it under ultrasonic conditions with a frequency of 20 to 100KHz and a power of 40 to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

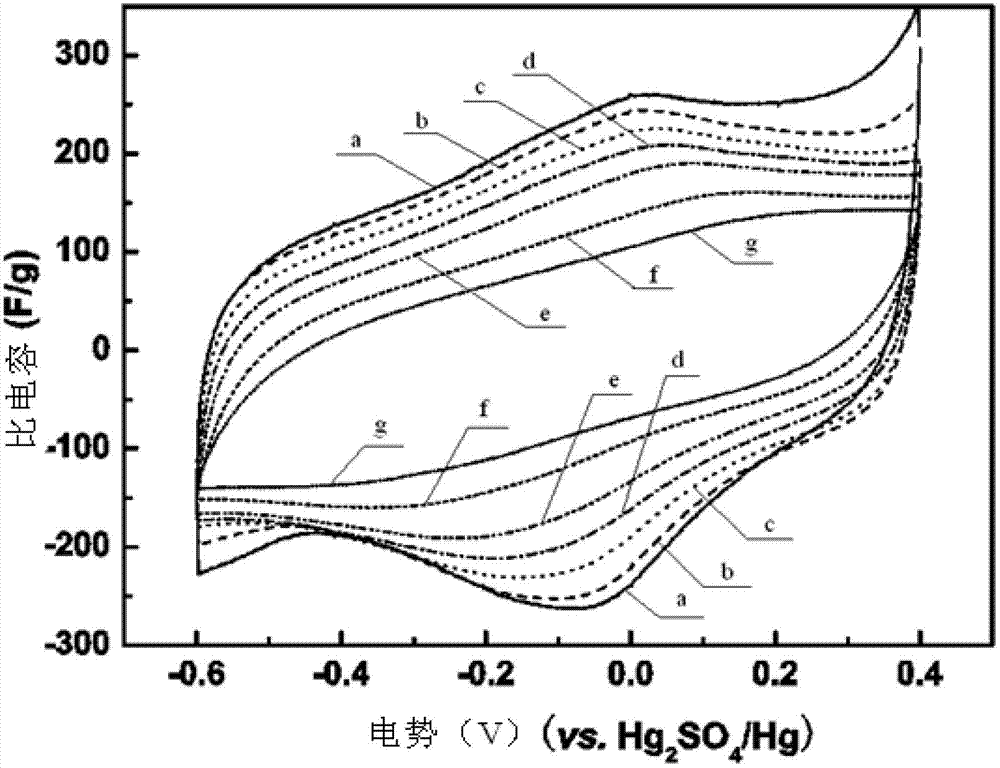

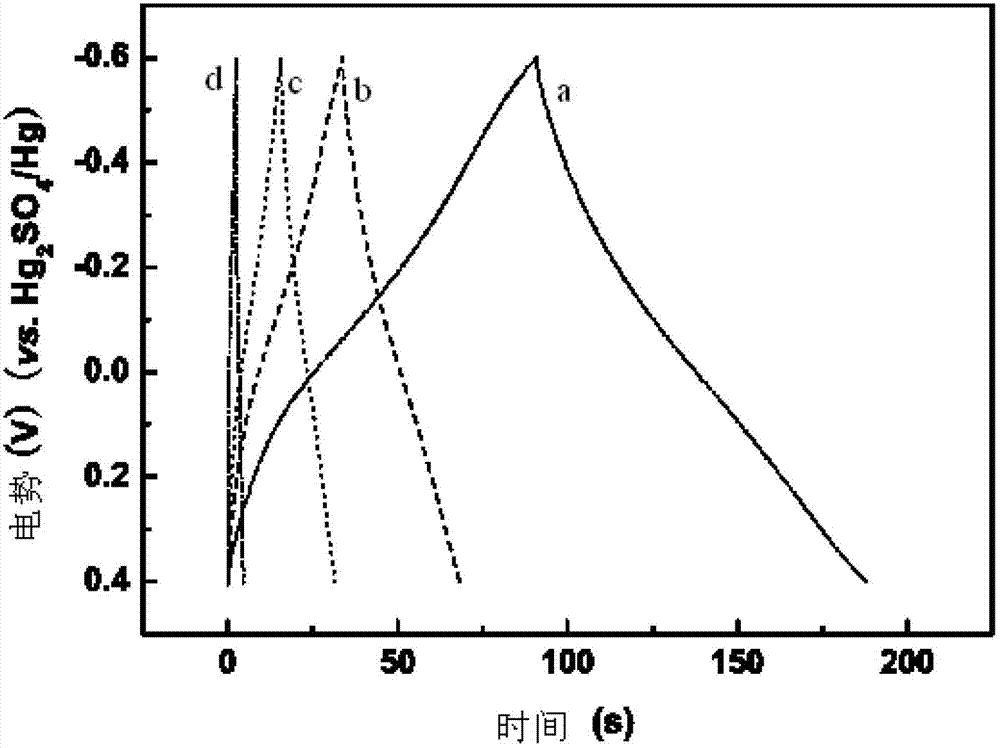

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com