Preparation method of molecular sieve primary structural unit pillared magnesium saponite

A technology of structural units and molecular sieves, applied in chemical instruments and methods, non-metallic elements, inorganic chemistry, etc., can solve problems such as layered pore structure damage, and achieve high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a preparation method of magnesium saponite supported by the primary structural unit of ZSM-5 molecular sieve, which comprises the following steps:

[0031] Intercalation reaction: Disperse 5g of stesterite into 100ml of deionized water, then add 15g of cetyltrimethylammonium bromide, react in a water bath at 60°C for 10h, then add 30g of tetrabutylammonium hydroxide, Stir at 80°C for 24 hours to prepare solution A;

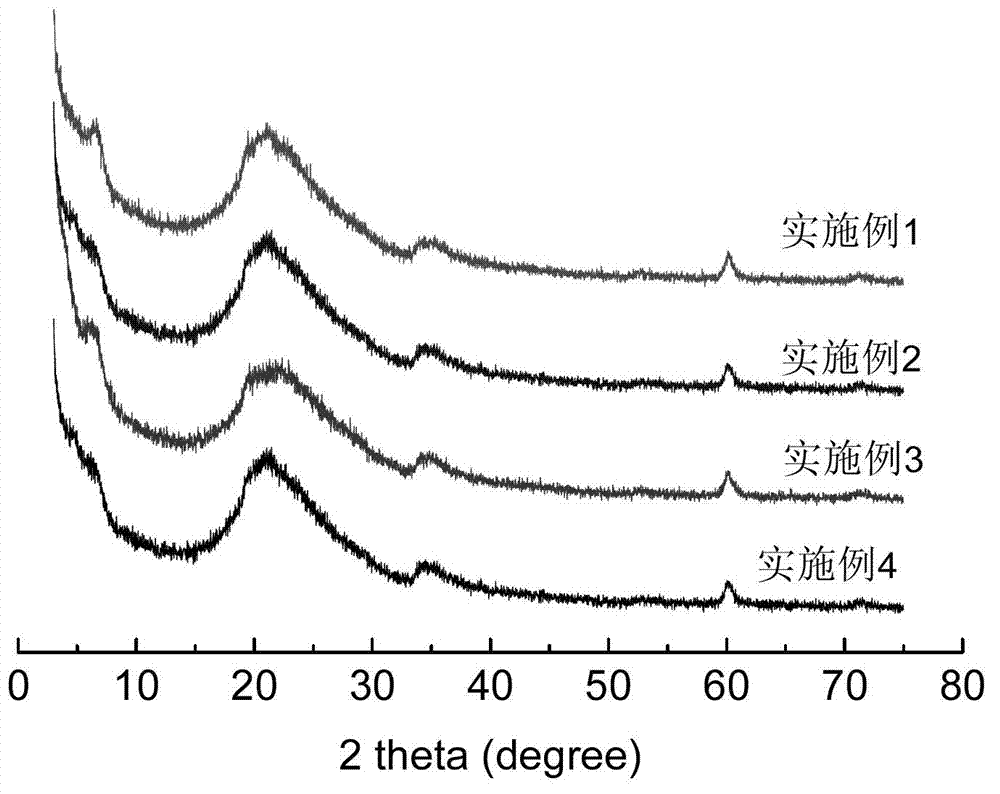

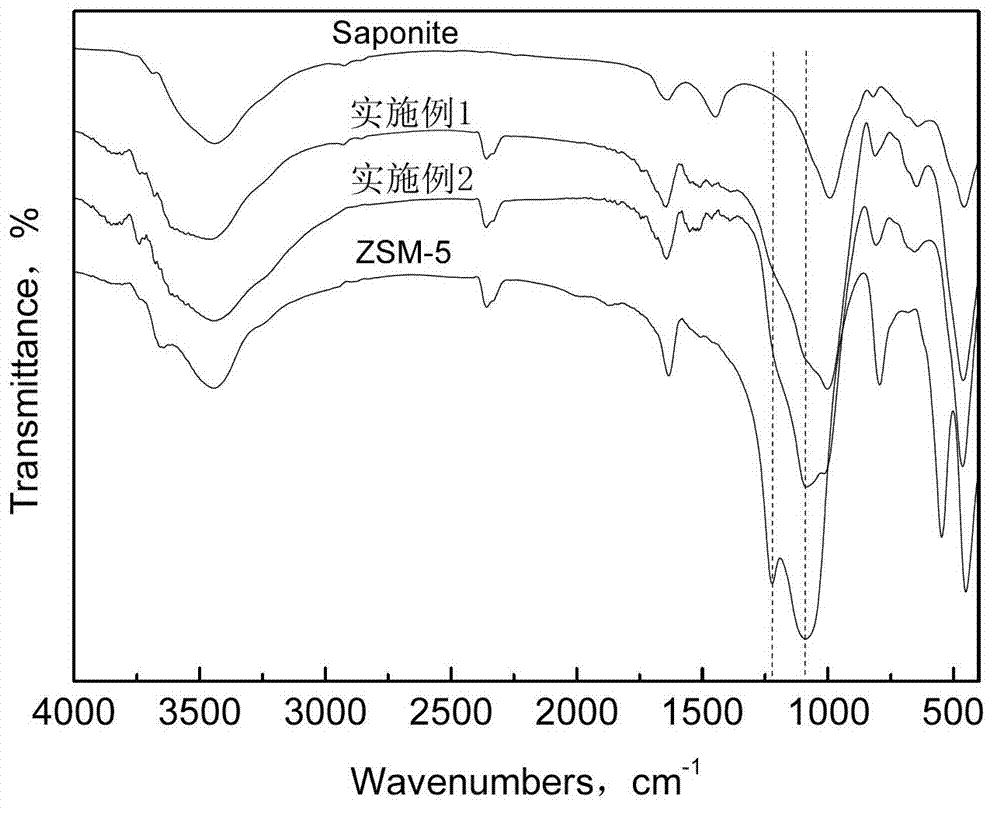

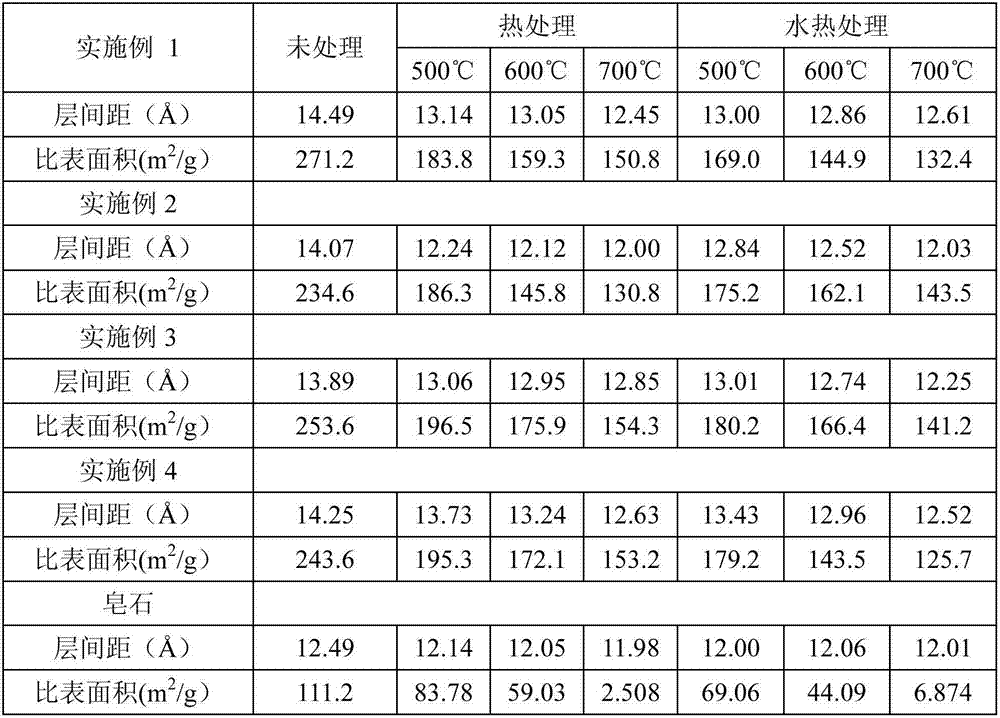

[0032] Preparation of pillared soapstone: 5.21gAl 2 (SO 4 ) 3 Soluble in 60g water and 5.88g H 2 SO 4 (concentrated sulfuric acid, the concentration is 98wt%), make a solution, then add 70g of silica sol and 20g of water, stir for 2h to make gel B; mix gel B with solution A, stir at 50°C for 15h , and finally crystallized at 90°C for 8 hours to obtain stesterite with pillared primary structural unit of ZSM-5 molecular sieve, and its XRD pattern is as follows figure 1 shown.

Embodiment 2

[0034] This embodiment provides a preparation method of magnesium saponite supported by the primary structural unit of ZSM-5 molecular sieve, which comprises the following steps:

[0035] Intercalation reaction: Disperse 5g of magnesium saponite into 100ml of deionized water, then add 10g of tetraethylammonium chloride, react in a water bath at 80°C for 5h, then add 20g of triethylamine, and stir at 40°C for 20h , to make solution A;

[0036] Preparation of pillared soapstone: 5.21gAl 2 (SO 4 ) 3 Soluble in 60g water and 5.88g H 2 SO 4 (concentrated sulfuric acid, the concentration is 98wt%), make a solution, then add 70g of silica sol and 20g of water, stir for 2h to make gel B; mix gel B with solution A, stir at 50°C for 15h , and finally crystallized at 90°C for 8 hours to obtain stesterite with pillared primary structural unit of ZSM-5 molecular sieve, and its XRD pattern is as follows figure 1 shown.

Embodiment 3

[0038] This embodiment provides a preparation method of magnesium saponite supported by the primary structural unit of ZSM-5 molecular sieve, which comprises the following steps:

[0039] Intercalation reaction: Disperse 5g of magnesium saponite into 100ml of deionized water, then add 20g of tetraethylammonium chloride and dihexadecyldimethylammonium bromide, react in a water bath at 70°C for 9h, and then add Add 20g of diethanolamine and stir at 60°C for 12h to prepare solution A;

[0040] Preparation of pillared soapstone: 5.21gAl 2 (SO 4 ) 3 Soluble in 60g water and 5.88g H 2 SO 4 (concentrated sulfuric acid, the concentration is 98wt%), make a solution, then add 70g of silica sol and 20g of water, stir for 2h to make gel B; mix gel B with solution A, stir at 50°C for 15h , and finally crystallized at 100°C for 12 hours to obtain the magnesium saponite supported by the primary structural unit of ZSM-5 molecular sieve, and its XRD pattern is as follows figure 1 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com