Method for treating coal water slurry gasification wastewater with microbes

A technology of microbial treatment and coal water slurry, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as difficulty in meeting discharge standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

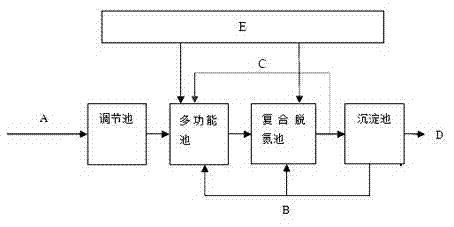

[0109]The following examples are running tests done by the present invention in a certain wastewater treatment project. The test is a closed test, and non-specific groups of people cannot touch and understand the test process.

[0110] like figure 2 As shown, four main units are spatially constituted by regulating pond, multifunctional pond, compound denitrification pond and sedimentation pond. After distilling ammonia from coal-water slurry gasification wastewater in a factory, it is injected into the multi-functional pool for denitrification and denitrification through the regulating pool. 2.5% activated carbon powder. Control temperature at 20~35℃, pH value 7.0~9, dissolved oxygen below 0.2mg / L, sludge sedimentation ratio SV 30 15%~30%, the residence time is 16~24 hours, the influent COD index is 200~760mg / L, and the effluent COD index is 150~300mg / L.

[0111] The wastewater treated by the multifunctional pool is then sent to the compound denitrification pool, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com