Resin material and preparation method thereof

A resin material and resin technology, applied in the field of resin material and its preparation, can solve the problems of not being able to obtain recycled materials, difficult to solve the problems of compatibility between waste polyester packaging and polymer resin, easy breakage, etc., and achieve good economical efficiency. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

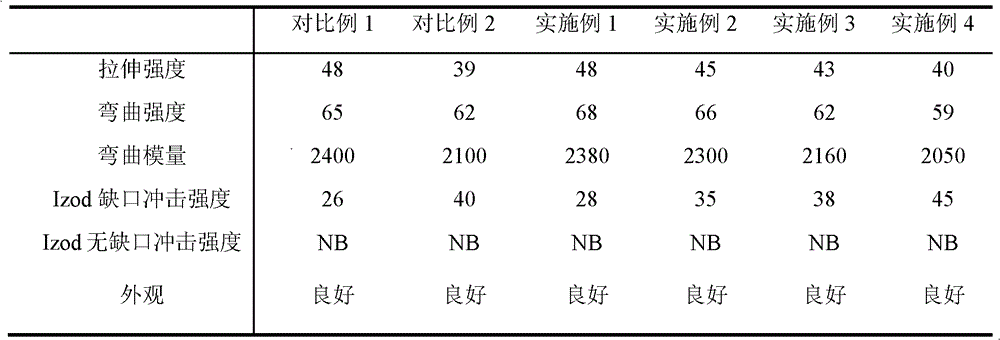

Embodiment 1

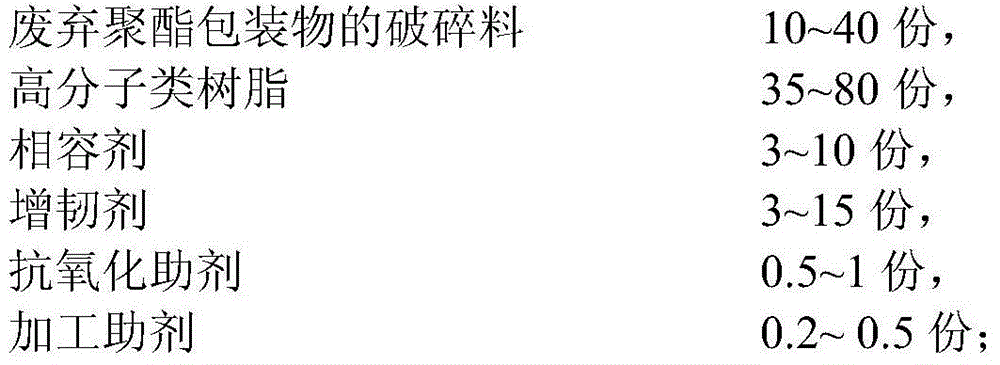

[0037] (1) above-mentioned each component is weighed 10 parts of broken material of discarded polyester packaging according to its weight percentage ratio, polymer resin Kumho acrylonitrile-butadiene-styrene graft copolymer 750 is 80 parts, 5 parts of compatibilizer I ABS-G, 4 parts of acrylonitrile-butadiene-styrene copolymer 181H as a toughening agent, 0.5 parts of processing aid N, N-ethylene bis stearic acid amide EBS, the main antioxidant Auxiliary tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester 1010 is 0.2 parts and auxiliary antioxidant tris[2.4-di-tert-butylphenyl] phosphite 168 is 0.3 copies;

[0038] (2) Put the above-mentioned raw materials into a high-speed mixer with a rotating speed of 100 rpm and fully mix them for 3 minutes;

[0039] (3) Use a precise metering and conveying device to send the mixed material in step (2) into the twin-screw extruder, and through the shearing action of the screw, fully mix, wherein the length-to-...

Embodiment 2

[0042] (1) above-mentioned each component is weighed 20 parts of broken material of discarded polyester packing material according to its weight percentage ratio, polymer resin Kumho acrylonitrile-butadiene-styrene graft copolymer 750 is 65 parts, Compatibilizer II Acrylate-butadiene copolymer EM500A 5 parts, toughening agent is acrylonitrile-butadiene-styrene copolymer 181H 8 parts, processing aid N, N-ethylene bis stearic acid amide EBS 0.5 parts, the main antioxidant auxiliary agent tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester 1010 is 0.1 part and the auxiliary antioxidant tris[2.4-di-tert-butyl Phenyl]phosphite 168 is 0.4 parts

[0043](2) Put the crushed material, polymer resin, compatibilizer, processing aid, toughening agent and anti-oxidant additive of the waste polyester packaging material weighed in the first step together into a rotating speed of 120 rpm Mix well in a high speed mixer for 2 minutes.

[0044] (3) Use a precise m...

Embodiment 3

[0047] (1) above-mentioned each component is weighed 30 parts of broken material of discarded polyester packaging according to its proportioning by weight, macromolecular resin Kumho acrylonitrile-butadiene-styrene graft copolymer 750 is 50 parts, 8 parts of compatibilizer II acrylate-butadiene copolymer EM500A, 11 parts of acrylonitrile-butadiene-styrene copolymer 181H as a toughening agent, 0.3 parts of pentaerythritol stearate as a processing aid, the main antioxidant The auxiliary agent β-(4-hydroxyphenyl-3,5-di-tert-butyl) n-octadecyl propionate 1076 is 0.2 parts and the auxiliary antioxidant tris[2.4-di-tert-butylphenyl]phosphorous acid 0.5 parts for ester 168

[0048] (2). Put the crushed material of waste polyester packaging weighed in the first step, polymer resin, compatibilizer, processing aid, toughening agent, antioxidant aid into a high-speed mixer with a rotation speed of 150 rpm Mix well for 1.5 minutes.

[0049] (3) Use a precise metering and conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com