High-potential metal seawater pipeline penetration piece with composite structure

A composite structure, high-potential technology, applied in the direction of pipes/pipe joints/fittings, passage components, pipes, etc., can solve problems such as steel corrosion of tank fittings, macro corrosion batteries, corrosion of steel inner tubes of tank fittings, etc. Achieve low cost, reduce openings and corresponding reinforcement requirements, and avoid electrochemical corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

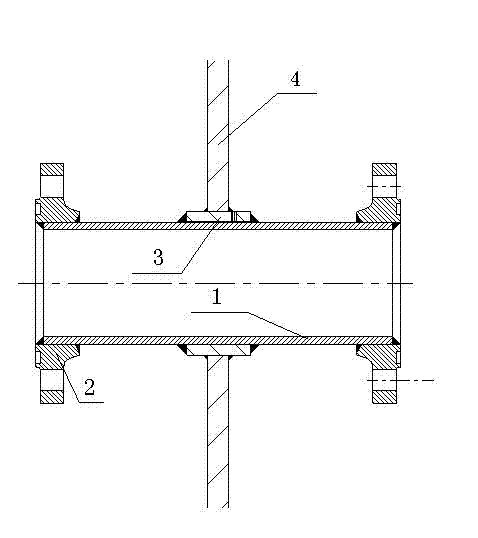

[0020] Such as figure 1 As shown, this embodiment provides a high-potential metal seawater pipeline tank fitting with a composite structure, which is composed of an inner pipe 1 , a flange 2 and a casing 3 . The inner pipe 1 and the flange 2 are made of copper, and the casing 3 is made of steel. The inner pipe 1 and the sleeve pipe 3 are concentric pipelines, the inner diameter of the sleeve pipe 3 is slightly larger than the outer diameter of the inner pipe 1, the length is shorter than the inner pipe 1, and greater than the structural thickness of the hull 4, the inner pipe 1 and the sleeve pipe 3 are fixedly connected by welding. The fixed connection position ensures that both ends of the inner pipe 1 can be fixedly connected to the flange 2, and the casing 3 and the hull 4 are connected by welding. In order to test the quality of the weld between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com