Multi-cell mechanical simulation experiment platform

A multi-cell, mechanical technology, applied in the field of multi-cell mechanical simulation experimental platform, can solve the problems of unreported, difficult to simulate accurately, steep and so on, and achieve the effect of uniform force on cells, improved accuracy and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

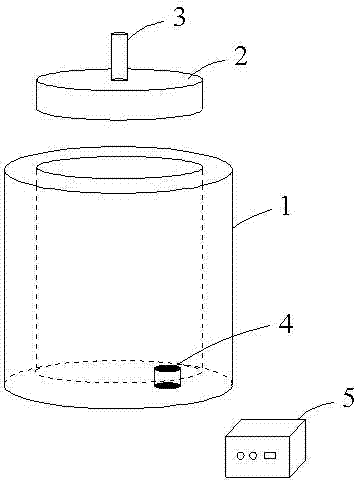

[0035] Example 1 A multicellular mechanical loading device of the present invention

[0036] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a multi-cell mechanical loading device of the present invention. The multicellular mechanical loading device is provided with a loading box 1. The loading box 1 is made of plexiglass and is cylindrical, with an outer diameter of 13 cm, an inner diameter of 10 cm, and a height of 13 cm. The upper side is open. The multicellular mechanical loading device is also provided with a piston 2, the piston 2 is cylindrical, the diameter is the same as the inner diameter of the loading box 1, and the thickness is 3cm. A support 3 is provided at the center of the upper end of the piston 2, and the support 3 is also a cylinder made of stainless steel. The bottom of the loading box 1 is provided with a through hole (not shown in the figure), and the sensor 4 is tightly fitted in the through hole. The sensor 4 is a wirel...

Embodiment 2

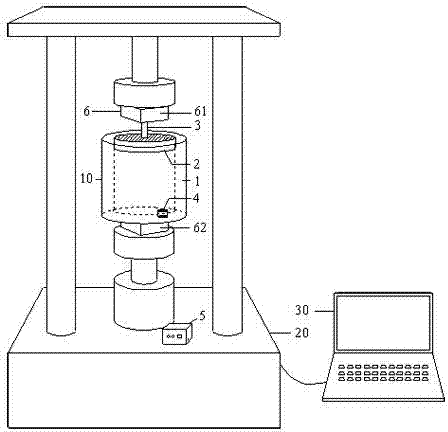

[0037] Example 2 A multicellular mechanical simulation experiment platform of the present invention

[0038] Please refer to figure 2 , figure 2 It is a structural schematic diagram of a multi-cell mechanical simulation experiment platform of the present invention. The multicellular mechanical simulation experiment platform is equipped with the multicellular mechanical loading device 10 , the universal material testing machine 20 and the computer system 30 as described in the first embodiment. The universal material testing machine 20 is produced by MTS Corporation of the United States, the model is MTS858, and it is provided with a clamp 6 . The clamp 6 includes a first clamp 61 and a second clamp 62 . The multicellular mechanical loading device 10 is fixed between the first fixture 61 and the second fixture 62 , that is, the support 3 is fixed with the first fixture 61 , and the bottom of the loading box 1 is fixed with the second fixture 62 . The computer system 30 i...

Embodiment 3

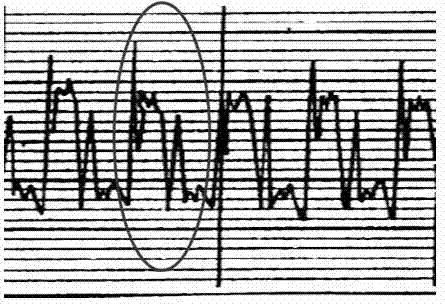

[0048] Embodiment 3 A kind of multi-cell mechanical simulation experiment platform of the present invention simulates the curve of the Kungfu method

[0049] 1. Experimental method

[0050] Based on the optimal dynamic parameters of the Knock method screened in clinical experiments (force 4kg, frequency 120 times / min, time 10min) as the basic parameters, combined with Ding Jifeng's medium-sized Knock method dynamic curve (see image 3 ) and the technical requirements of the universal material testing machine 20, use the waveform editing program in the computer system 30 to design and regulate the output of the loading force of the multicellular mechanical loading device 10, the specific operation steps are:

[0051] ① Fix the multicellular mechanical loading device 10 after ultraviolet irradiation on the universal material testing machine 20, switch on the power supply of the sensor 4 at the bottom of the loading box 1, turn on the data acquisition instrument 5, adjust the z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com