Accuracy control method for single-phase diode clamping three level midpoint potential imbalance

A diode clamping and potential unbalanced technology, applied in electrical components, output power conversion devices, AC power input conversion to DC power output, etc., can solve midpoint potential fluctuations in modulation methods and realize complex, diode clamping topologies Solve problems such as midpoint potential fluctuations, achieve the effect of simple method and good reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

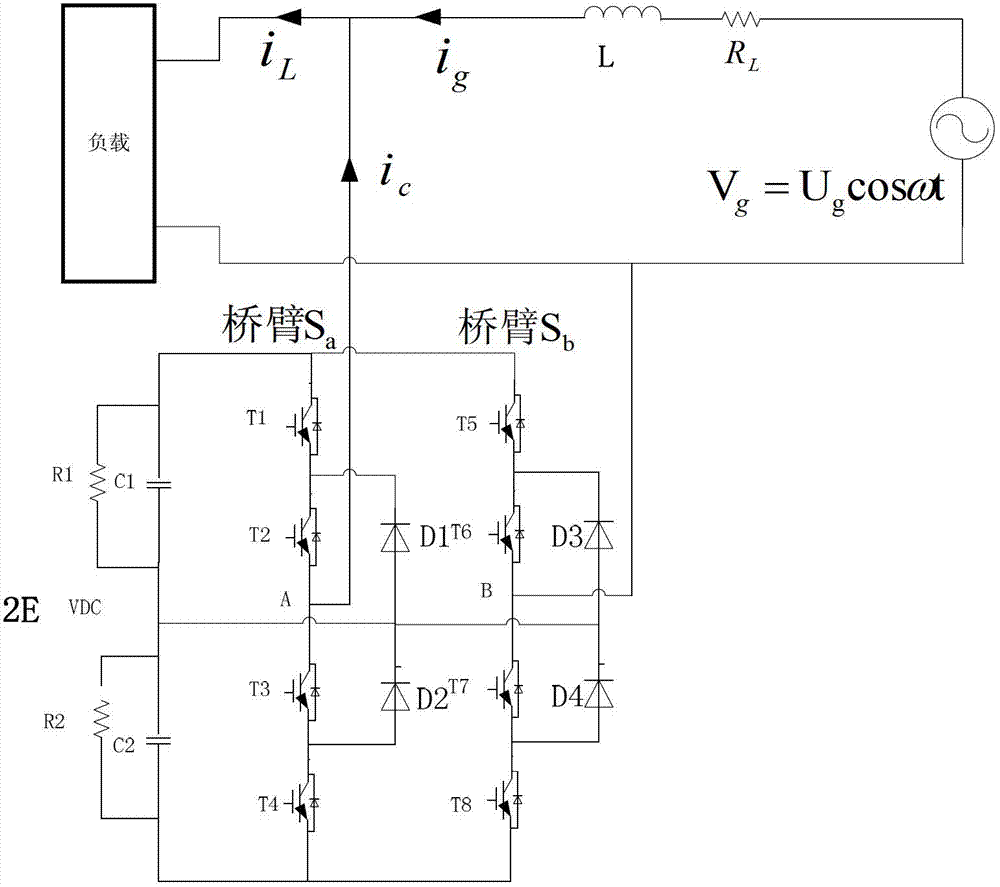

[0067] refer tofigure 1 , a diode clamp topology three-level grid-connected converter is connected between the grid and the load, and the grid-connected converter operates as a reactive power compensator. In order to better verify the control effect of the control method on the midpoint, the Side C 1 A small resistor R is added to the terminal 1 To simulate its large loss, so a large active component will be used in the experimental current. The main circuit structure of the diode-clamped multilevel grid-connected converter mainly includes: a diode-clamp topology module, an incoming line inductance, and a load side. Each diode clamp topology module is composed of two DC side energy storage capacitor elements and a voltage source PWM converter, in which the DC side energy storage element is generally composed of power capacitors connected in series and parallel, and the voltage source PWM converter uses a fully controlled device Such as IGBT, GTO and other components.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com