Injection bone filling composition

A composition and injection technology, which is applied in the field of bone filling materials, can solve the problem of short operation time interval and achieve the effect of reducing the possibility of operation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

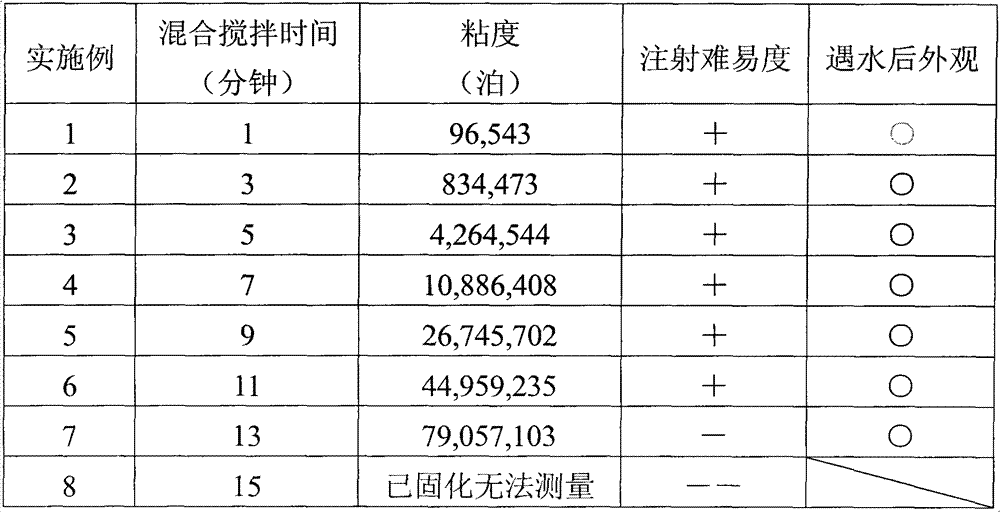

[0021] Take 7 grams of calcium sulfate hemihydrate (average particle size 10 μm) and 8 grams of HA (average particle size 2 μm) and mix them uniformly. Take 6 grams of distilled water, add it to the mixed powder at room temperature, and stir with a hand-held stirring rod at a stirring rate of 1 revolution / second for 50 seconds to form a slurry. Afterwards, after standing for 1, 3, 5, 7, 9, 11, 13, and 15 minutes, take 5 grams of the slurry respectively, use the AR-G2 rheometer (TA Instruments), and according to its operation manual, to Viscosity was determined by the parallel plate viscosity test method. At the same time, another 5 grams of slurry was filled into the injection cylinder (the inner diameter of the injection port was 0.3 cm), and then the slurry was extruded from the injection cylinder and injected into distilled water. The appearance of the slurry was then observed to see if it maintained its shape or fell apart. The test results are shown in Table 1:

[0022...

Embodiment 9~15

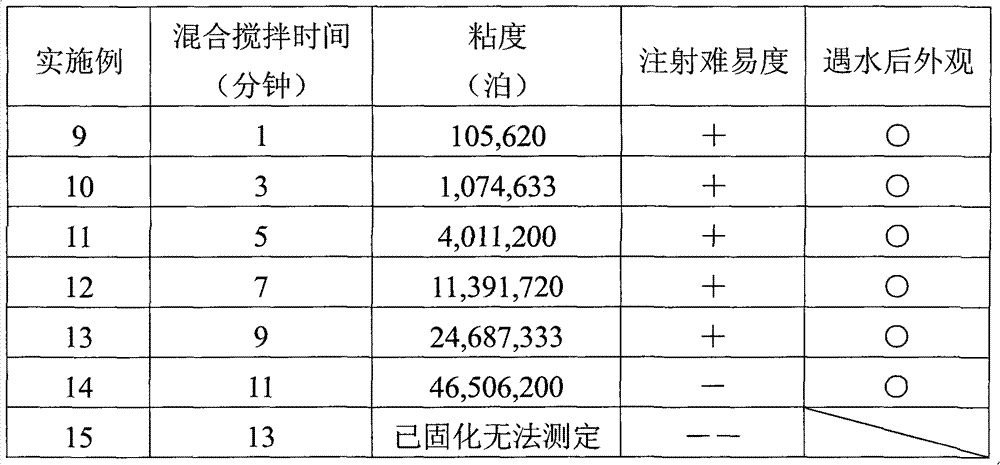

[0029] Take 15.8 grams of calcium sulfate hemihydrate (average particle size 950 nm) and 5.2 grams of HA (average particle size 42 μm) and mix them uniformly. Take 6.5 g of distilled water, add it to the mixed powder at room temperature, and then stir with a hand-held stirring rod at a stirring rate of 1 revolution / second for 50 seconds to form a slurry. Afterwards, after standing for 1, 3, 5, 7, 9, 11, and 13 minutes, take 5 grams of the slurry to test according to the detection methods and conditions of Examples 1-8, and the test results are shown in Table 2:

[0030] Table II

[0031]

[0032] Note: "+": easy to inject; "-": slightly difficult to inject, but still injectable; "—": unable to inject; "△": slightly spread out, but can still roughly maintain its shape; "○": won't fall apart

[0033] From the test results obtained in Examples 9-15, it can be found that the injectable bone filling composition of the present invention can be used as an injectable bone cement ...

Embodiment 16~22

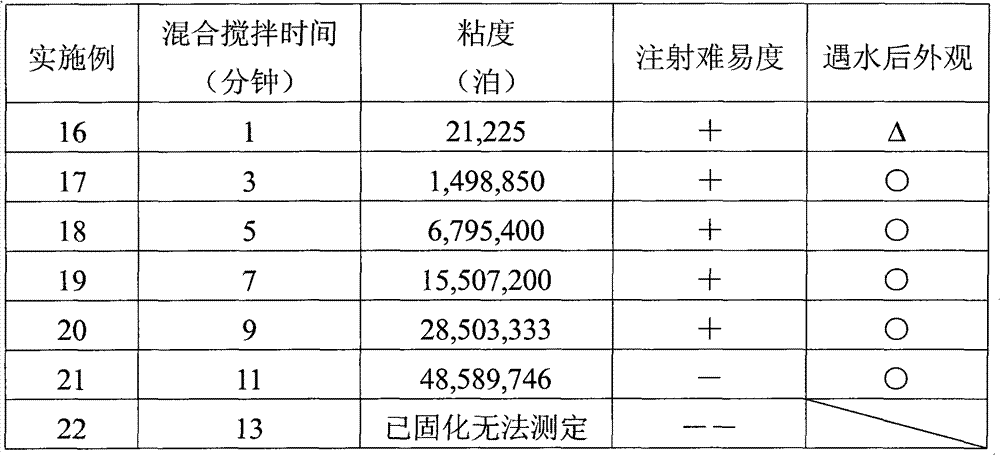

[0037] Take 10 grams of calcium sulfate hemihydrate (average particle size 33 μm), 2.36 grams of HA (average particle size 9 μm) and 2.36 grams of tricalcium phosphate (average particle size 3 μm) and mix them uniformly. Take 6.5 g of physiological saline, add it to the above mixed powder at room temperature, and then stir with a hand-held stirring rod at a stirring rate of 1 revolution / second for 50 seconds to form a slurry. Afterwards, after standing for 1, 3, 5, 7, 9, 11, and 13 minutes, take 5 grams of the slurry to test according to the detection methods and conditions of Examples 1-8, and the test results are shown in Table 3:

[0038] Table three

[0039]

[0040] Note: "+": easy to inject; "-": slightly difficult to inject, but still injectable; "—": unable to inject; "△": slightly spread out, but can still roughly maintain its shape; "○": won't fall apart

[0041] From the test results obtained in Examples 16-22, it can be found that the injectable bone filling c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com