Method for manufacturing aerated hollow bricks by abandoned construction waste

A technology for construction waste and hollow bricks is applied in the field of preparing aerated hollow bricks, which can solve the problems of unimplemented industrial realization, flying lime and sand, pollution and other problems, and achieves the effects of light bulk density, large amount of use and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Referring to the accompanying drawings, a method for preparing air-entraining hollow bricks by using waste construction waste is carried out according to the following steps:

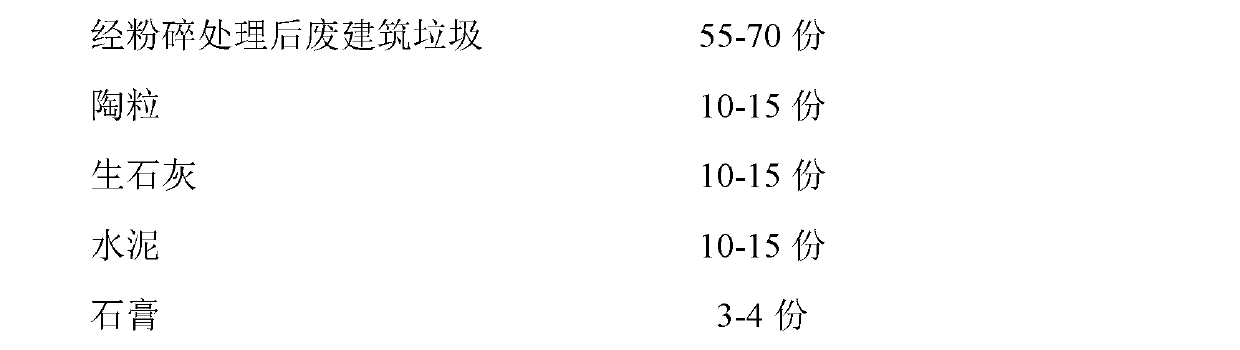

[0025] (1) Mix the raw materials according to the following parts by weight on a dry basis:

[0026] 55 copies of waste construction waste after crushing

[0027] Ceramsite 15 parts

[0028] Quicklime 10 parts

[0029] 12 parts of cement

[0030] 3 parts plaster

[0031] (2) According to the above steps (1) add water to 85% of the dry basis of the mixed raw materials, add waste aluminum powder to 0.05% of the dry basis of the mixed raw materials, add methyl cellulose ether to 0.8%, and add acetyl triethyl citrate to 2%. Esters, 0.2% by weight of lime plus triethanolamine;

[0032] (3) Put the slurry stirred in the above step (2) at a temperature of 65°C, and foam for 30-40 minutes;

[0033] (4) The foaming slurry in the above step (3) is steam-cured under nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com