Polymer cement-based self-leveling grouting material

A grouting material and cement-based technology, applied in the field of grouting materials, can solve the problems of affecting load, slow strength growth, poor durability, etc., and achieve the effect of large adjustment range, low price and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

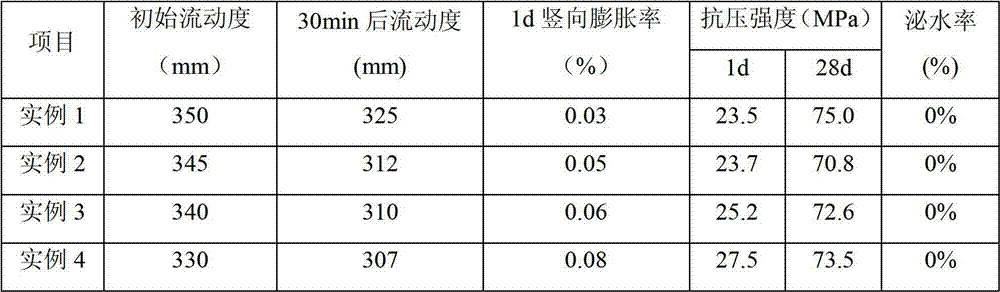

Examples

Embodiment 1

[0011] A preparation method of a polymer cement-based self-leveling grouting material is as follows:

[0012] Step 1: take each raw material by weight percentage;

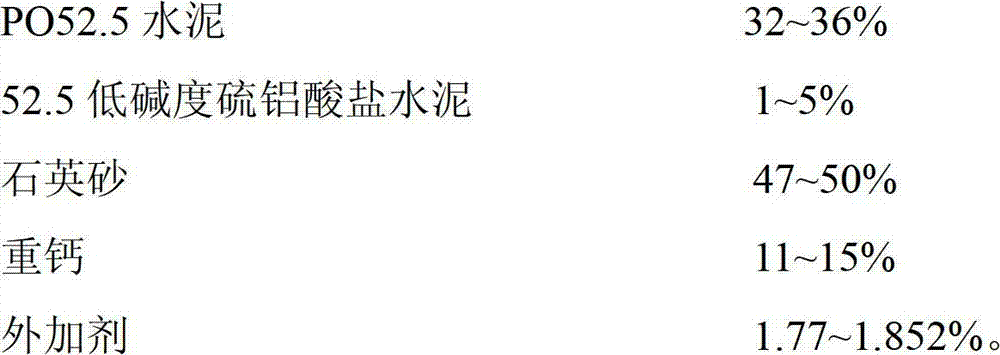

[0013] PO52.5 cement 35.6%, 52.5 low alkalinity sulfoaluminate cement 1.1%, quartz sand 48.56%, heavy calcium 12.9%, Wacker 5044N rubber powder 0.73%, polycarboxylate superplasticizer 0.37%, calcium formate early strength Agent 0.37%, methyl cellulose ether 0.012%, polysiloxane defoamer 0.32%;

[0014] Step 2: Put the weighed raw materials in a forced mixer and mix evenly, then pack them into bags, and transport them to the construction site after passing the inspection. It can be used by adding 14.5% (mass percentage) of tap water during use.

Embodiment 2

[0016] A preparation method of a polymer cement-based self-leveling grouting material is as follows:

[0017] Step 1: take each raw material by weight percentage;

[0018] PO52.5 cement 33.9%, 52.5 low alkalinity sulfoaluminate cement 2.2%, quartz sand 47.79%, heavy calcium 14.3%, Wacker 5011L rubber powder 0.73%, naphthalenesulfonate formaldehyde condensation product water reducer 0.36%, Calcium chloride early strength agent 0.36%, hydroxyethyl cellulose ether 0.010%, polysiloxane defoamer 0.31%;

[0019] Step 2: Put the weighed raw materials in a forced mixer and mix evenly, then pack them into bags, and transport them to the construction site after passing the inspection. It can be used by adding 15% (mass percentage) of tap water when used.

Embodiment 3

[0021] A preparation method of a polymer cement-based self-leveling grouting material is as follows:

[0022] Step 1: take each raw material by weight percentage;

[0023] PO52.5 cement 33.8%, 52.5 low alkalinity sulfoaluminate cement 3.0%, quartz sand 48.56%, heavy calcium 12.9%, Wacker 7055N rubber powder 0.73%, sulfonated melamine formaldehyde resin water reducer 0.38%, calcium formate Early strength agent 0.38%, methyl cellulose ether 0.012%, emulsified silicone oil defoamer 0.32%;

[0024] Step 2: Put the weighed raw materials in a forced mixer and mix evenly, then pack them into bags, and transport them to the construction site after passing the inspection. It can be used by adding 14.5% (mass percentage) of tap water during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com