Method for preparing 5-methylfurfural

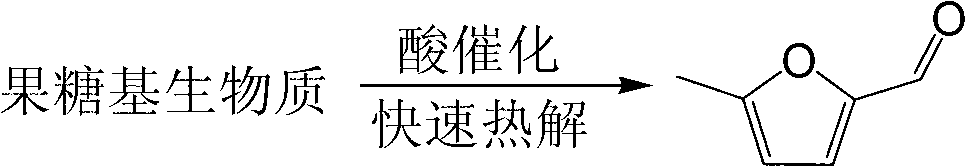

A methyl furfural and fructosyl technology, applied in the field of organic matter preparation, can solve problems such as expensive catalyst, long reaction time, environmental pollution, etc., achieve the effects of reducing corrosiveness and pollution, low cost, and avoiding pretreatment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

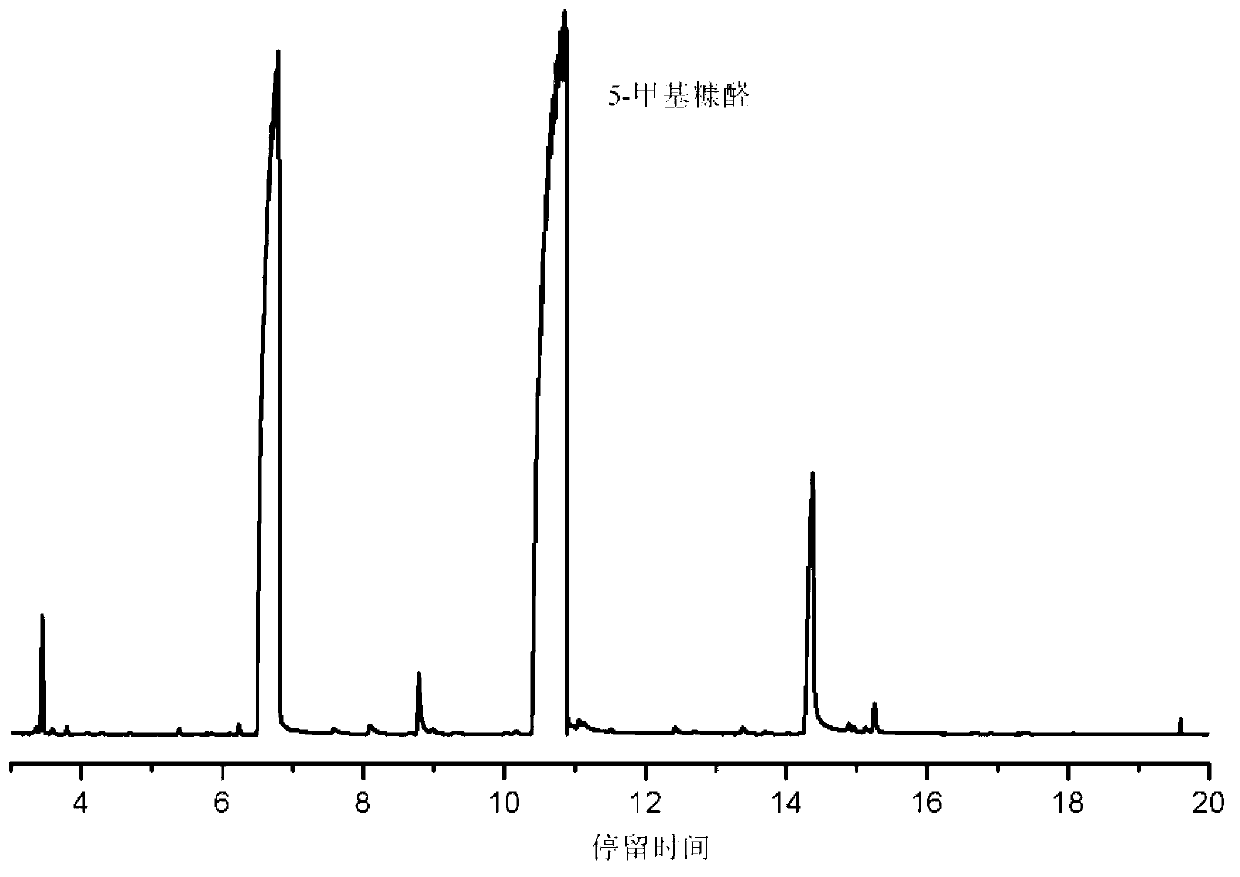

Embodiment 1

[0039] Put 10g of inulin into 100ml of sulfuric acid with a concentration of 0.1M and impregnate it, then dry it and pulverize it. After the treatment, the inulin containing sulfuric acid is pyrolyzed at 350°C, and the liquid is collected to obtain Bio-oil of furfural. The obtained bio-oil containing 5-methylfurfural is extracted with common weakly polar organic solvents such as cyclohexane and ethyl acetate to obtain an organic phase and an aqueous phase, respectively. The organic phase is evaporated at 110°C under normal pressure to remove organic solvents and low-boiling components, and finally vacuum distillation controls the boiling point to 70-80°C to obtain the product 5-methylfurfural, which is then detected and analyzed by gas chromatography to obtain 5-methylfurfural. - The yield of methylfurfural is 18%.

Embodiment 2

[0041] Immerse 10g of inulin in 100ml of a mixed solution of sulfuric acid and boric acid with a concentration of 0.8M, and then dry and pulverize it. After the treatment, the inulin containing sulfuric acid and boric acid is pyrolyzed at 400°C, and the liquid is collected. That is, bio-oil containing 5-methylfurfural is obtained. The bio-oil product was separated and purified to obtain 5-methylfurfural (the method of separation and purification is as in Example 1), and then detected by gas chromatography, the yield was 10%.

Embodiment 3

[0043]Put 10g of silicon-aluminum nano-solid acid into 100ml of 1M sulfuric acid solution for immersion, filter and dry, load the sulfuric acid onto the solid acid, mix 2g of solid acid with 3g of inulin, and perform pyrolysis at 450°C to collect the liquid , to obtain bio-oil containing 5-methylfurfural. The bio-oil product was separated and purified to obtain 5-methylfurfural (the separation and purification means are as in Example 1), and the yield was 12% through gas chromatography detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com