Modified biological asphalt material, biological asphalt mixture, preparation method thereof and applications

A bio-asphalt and mixture technology, which is applied to building insulation materials, building structures, building components, etc., can solve problems such as high price, poor ecological environmental protection, exhaustion of petroleum asphalt resources, etc., to achieve low cost and reduce dependence , Improve the effect of comprehensive use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the preparation method of the described bio-asphalt of the present invention, wherein the combination scheme of distillation process, extraction process, oxidation process and blending process is preferably:

[0039] (1) The bio-oil is first processed by distillation process to obtain the intermediate product of bio-asphalt, and then processed by oxidation process to obtain bio-asphalt;

[0040] (2) The bio-oil is first processed by distillation process under different conditions to obtain different bio-asphalt intermediate products, and then the different bio-asphalt intermediate products are processed by blending process to obtain bio-asphalt;

[0041] (3) Bio-oil is first processed by distillation process to obtain bio-asphalt intermediate product 1, and then processed by oxidation process to obtain bio-asphalt intermediate product 2, and then bio-asphalt intermediate product 1 and bio-asphalt intermediate product 2 are processed by blending process to obtain bio-a...

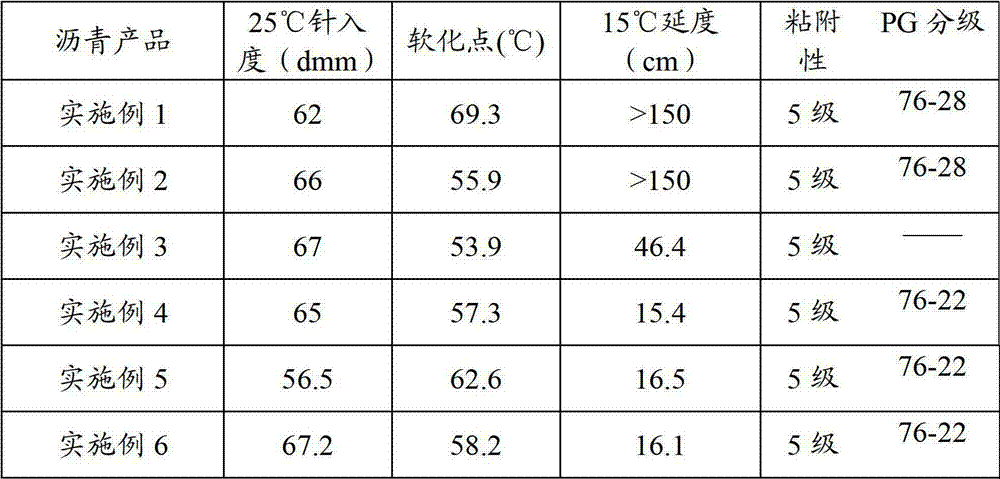

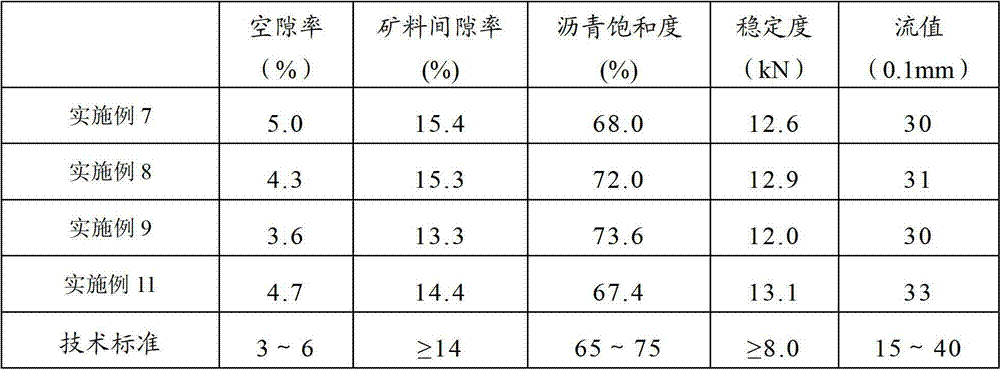

Embodiment

[0068] Raw materials used in each embodiment:

[0069] Bio-oil: Anhui Yineng Biomass Energy Co., Ltd.;

[0070] Base asphalt: Zhonghai No. 70 petroleum asphalt;

[0071] Rock asphalt: Shandong Road and Bridge Group;

[0072] SBS: Yueyang Petrochemical, grade YH-791H, S / B ratio is 30 / 70, density 0.94g / cm 3 , Melt index (190°C, 2.16Kg) 0.5g / 10min.

[0073] Low-density polyethylene (LDPE): Nanjing Yangzi Petrochemical Refining and Chemical Co., Ltd., grade 2426H, density 0.922-0.926g / cm 3 , Melt index (190°C, 2.16Kg) 1.7-2.2g / 10min.

[0074] Waste rubber powder: Beijing Fanyang Huateng Technology Co., Ltd., 80 mesh.

[0075] SBR: Jilin Chemical Industry Co., Ltd.

[0076] Rubber oil: purchased from Shandong Dongying Furunda Chemical Co., Ltd.

[0077] Aromatic oil: the content of light components is between 65% and 75%, Huludao Yuntian Industry and Trade Co., Ltd.

[0078] Stabilizer: purchased from Petrochemical Science Research Institute, off-white granules.

[0079] M...

preparation example 1

[0084] Using an atmospheric distillation device, 1000g of bio-oil is gradually heated to 150°C, and the bio-oil fraction with a boiling point greater than 150°C is separated; the time is 6.5h, and then the distillation product is aged in the oxidation tower for 0.5h to make the fraction obtained from distillation Bio-asphalt was obtained by sufficient thermo-oxidative aging.

[0085] The bio-asphalt and rubber oil obtained above were stirred at 140°C for 2 hours at a ratio of 9:1 to obtain bio-asphalt composition 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com