Diazo dye and its black ink composition

A disazo and composition technology, applied in the field of disazo water-soluble dye compounds, can solve the problem that raw materials are harmful to the body, cannot provide ozone resistance, light fastness, printing quality, light fastness and water fastness are not good, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

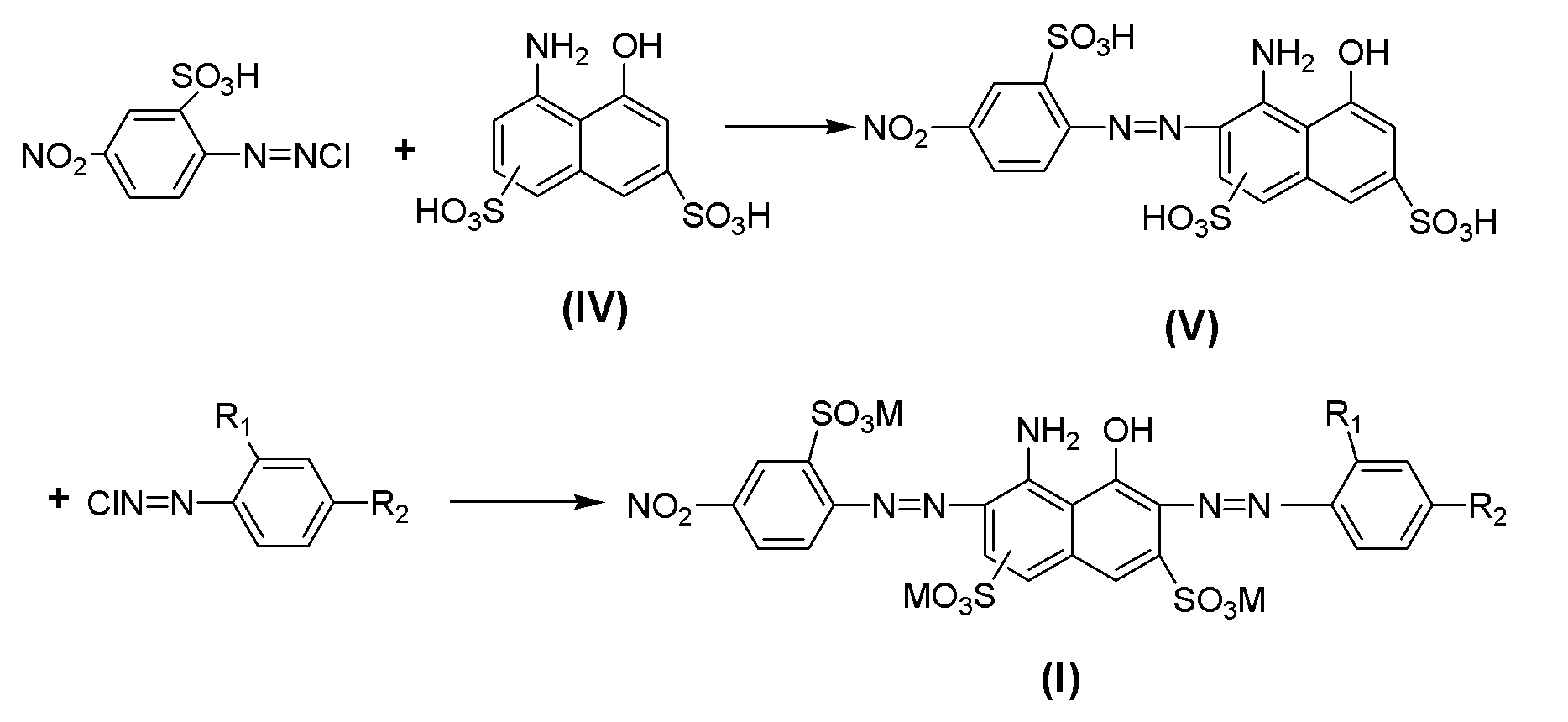

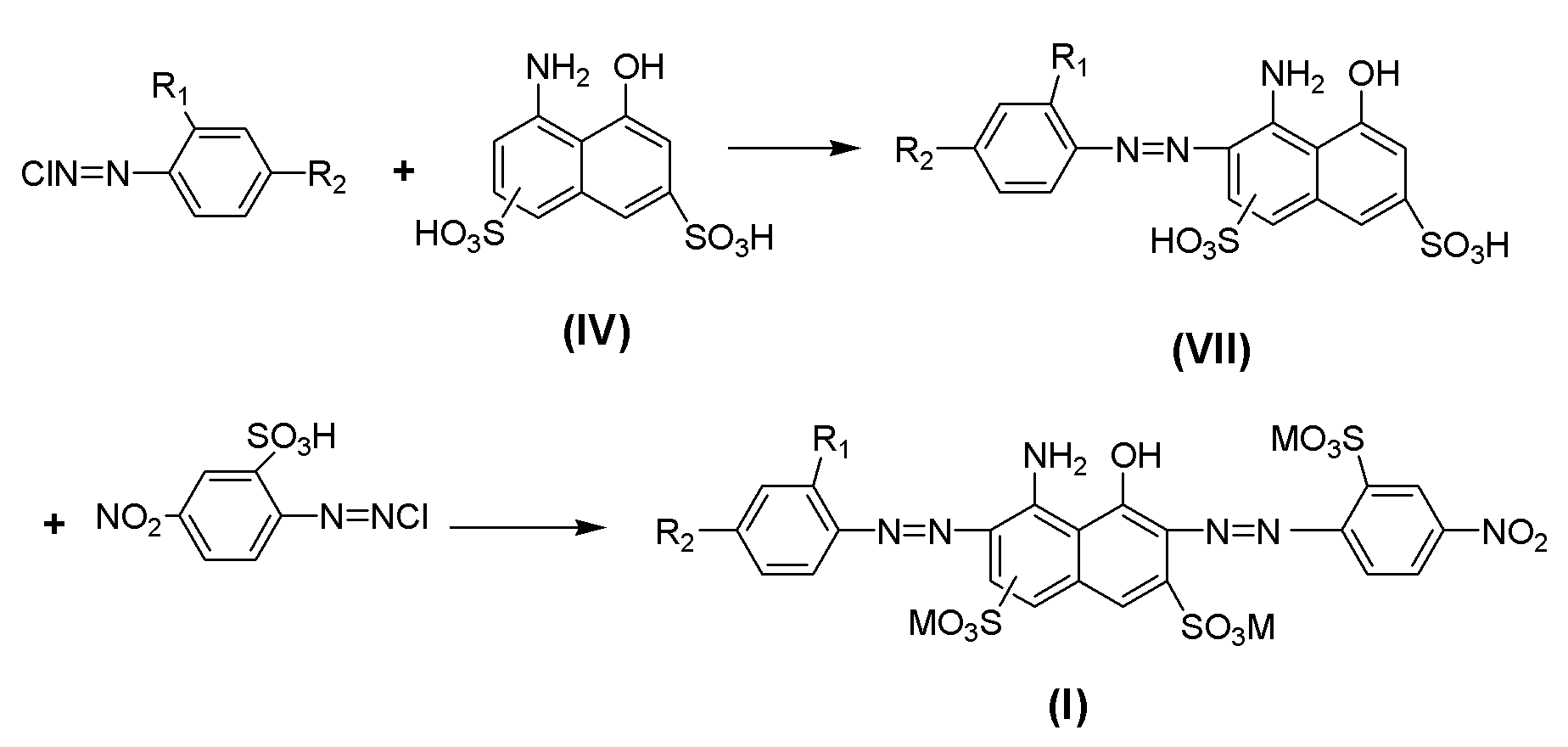

[0061] The preparation process of formula (I) compound is as figure 1 Shown. The preparation process of the compound of formula (II) is as follows figure 2 Shown.

[0062] Preparation of compound of formula (I)

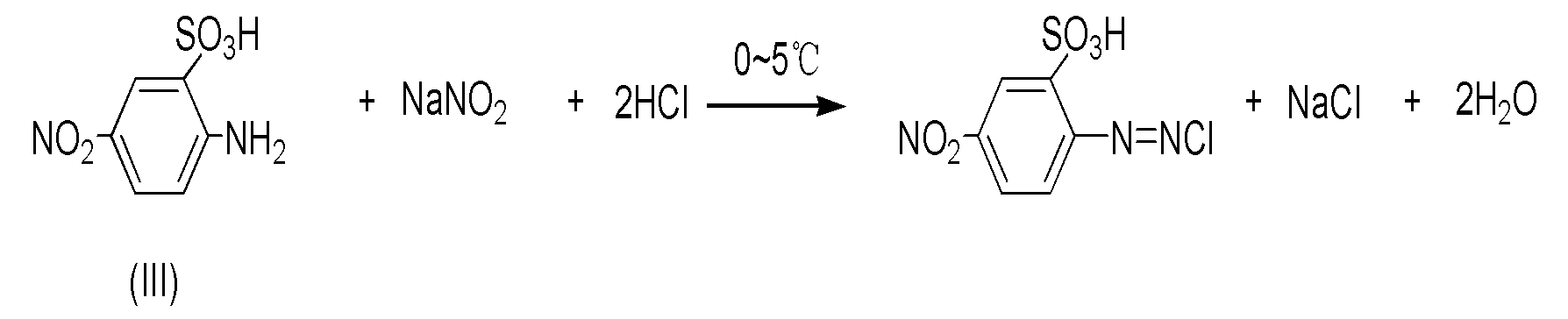

[0063] First, the diazotization reaction of the compound of structural formula (III) is performed. image 3 It is the diazotization reaction formula of the compound of structural formula (III).

[0064] Under acidic conditions with an ice-water bath temperature of 0-5°C and a pH of 1-2, the compound of structural formula (III), together with sodium nitrite and concentrated hydrochloric acid, undergo a diazotization reaction. The molar ratio of the three added amounts is 1:1 to 1.1: 2.5 to 4. After 2.5 to 4 hours of reaction, the diazotization reaction ends. Use starch potassium iodide test paper to determine whether there is residual nitrous acid in the reaction solution. If the test paper turns blue immediately after contact with the reaction solution, it is proved tha...

Embodiment 1

[0080] Preparation of compound (VIII) (M is Na + ):

[0081]

[0082] Under the condition of constant stirring, 4.69 parts of p-nitroaniline o-sulfonic acid (purity of 93%) were dissolved with water, and the amount of water used was to completely dissolve the solid powder of p-nitroaniline o-sulfonic acid. Then, add it to 5.8mL concentrated hydrochloric acid aqueous solution, ice water bath, control the temperature at 2℃, 1.39 parts NaNO 2 After dissolving in water, slowly add dropwise to the above solution (the amount of water is only NaNO 2 Completely dissolve). After the dropwise addition is completed, maintain the temperature at 4° C. to carry out the diazotization reaction for 3 hours. After the reaction is completed, sulfamic acid is added, and the remaining nitrous acid is removed by reacting sulfamic acid with nitrous acid.

[0083] Dissolve 4.0 parts of 1-amino-8-naphthol-3,6-disulfonic acid (purity 92%) in water (the amount of water is only to completely dissolve the compo...

Embodiment 2

[0088] Preparation of compound (IX) (M is Na + ):

[0089]

[0090] Under the condition of constant stirring, 2.35 parts of p-nitroaniline o-sulfonic acid (purity: 93%) were dissolved in water (the amount of water was only to completely dissolve the compound), and then added to 2.9 mL of concentrated hydrochloric acid aqueous solution, ice-water bath, control Temperature at 2℃, 0.69 parts NaNO 2 Dissolve in water (the amount of water only dissolves the compound completely) and then slowly add dropwise to the above solution. After the dropwise addition is completed, maintain the temperature at 4°C for diazotization reaction for 3 hours. After the reaction, add sulfamic acid and pass the amino acid. The sulfonic acid reacts with nitrous acid to remove the remaining nitrous acid.

[0091] Dissolve 4.0 parts of 1-amino-8-naphthol-3,6-disulfonic acid (purity 92%) with water (the amount of water only dissolves the compound completely), add it to the above diazonium solution, and carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com