Smoke waste heat utilizing system at tail of power station boiler applicable to operation in variable working condition

A flue gas waste heat and variable working condition technology, which is applied in the direction of steam boilers, process efficiency improvement, furnaces, etc., can solve the problems of aggravated pipe wall corrosion, ash deposition corrosion, low temperature pipe wall corrosion, etc., to reduce pitting corrosion, Improve the effect of circumvention and reduce the effect of rotation dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention provides a waste heat utilization system of flue gas at the tail of a power plant boiler adapted to variable working conditions. The following will be described in conjunction with the accompanying drawings and embodiments.

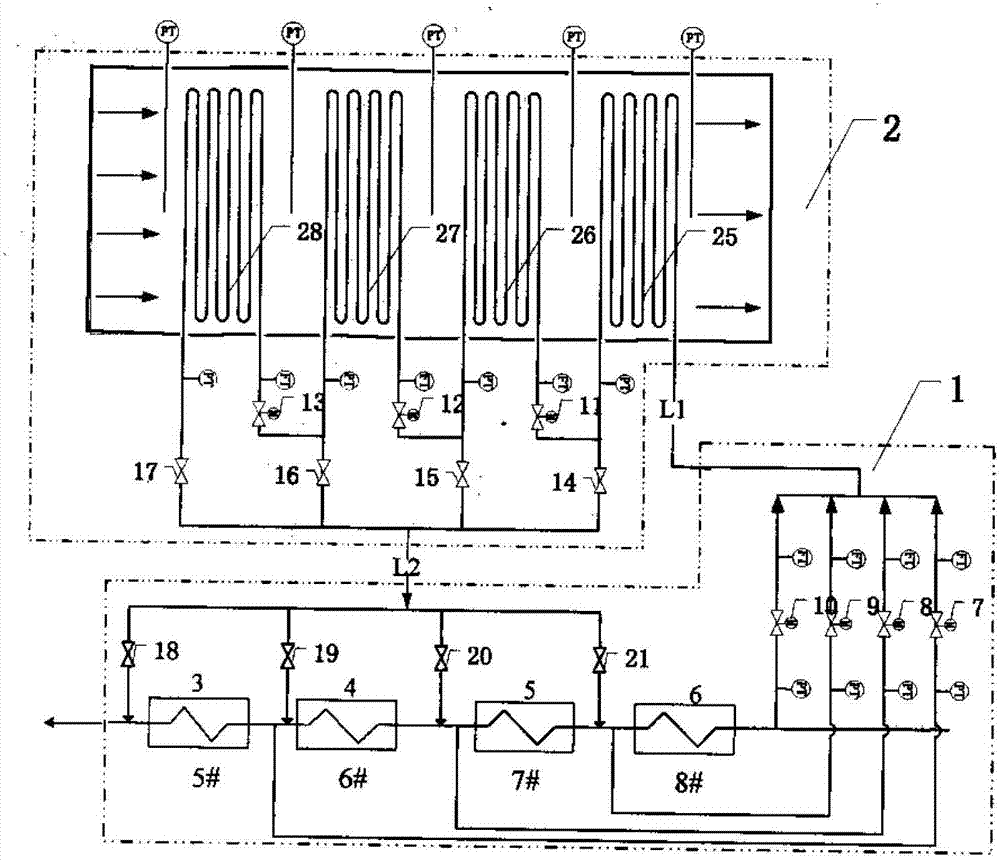

[0016] Such as figure 1 Shown is the specific piping and valve control schematic diagram of the flue gas waste heat utilization optimization integrated system. The system is mainly composed of the heat recovery side subsystem 1 and the staged heat exchange subsystem 2 distributed in the tail flue. Among them, the heat recovery side subsystem 1 is composed of 5# low-pressure heater 3, 6# low-pressure heater 4, 7# low-pressure heater 5 and 8# low-pressure heater 6 in series; it is connected at the entrance of 5# low-pressure heater 3 The 7th valve is connected to the 8th valve at the entrance of 6# low pressure heater 4, the 9th valve is connected to the entrance of 7# low pressure heater 5 and the 10th valve is connected to the entra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com