Support vector machine inverse-based bearingless asynchronous motor control system

A support vector machine technology for inverse and asynchronous motors, applied in vector control systems, electronic commutation motor control, control systems, etc., can solve problems such as difficult dynamic performance of the system, difficult optimization of network structure, and destruction of decoupling conditions. Achieve the effect of overcoming more complexity and relying on expert experience, fast and easy learning process, and overcoming dynamic decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention clear, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

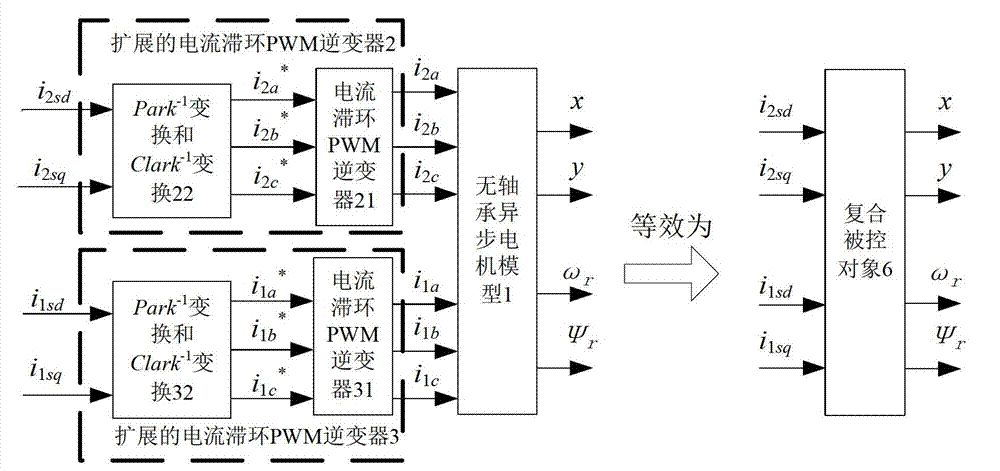

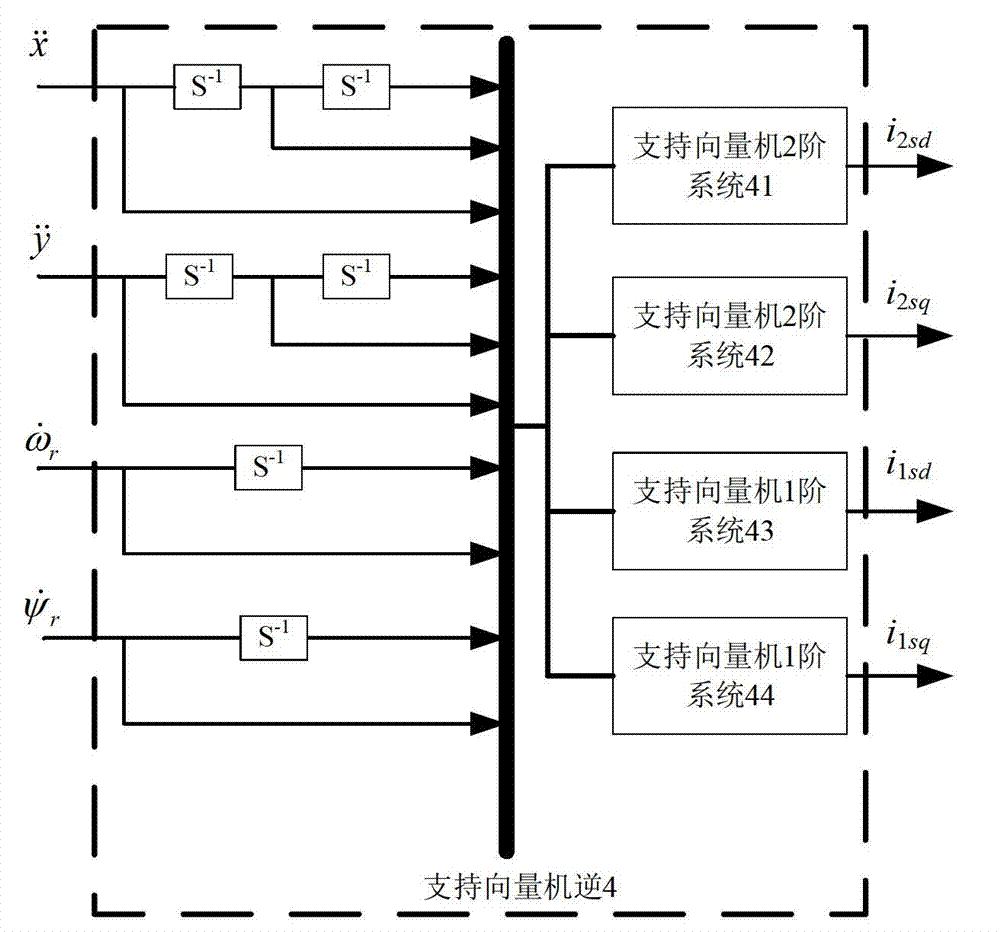

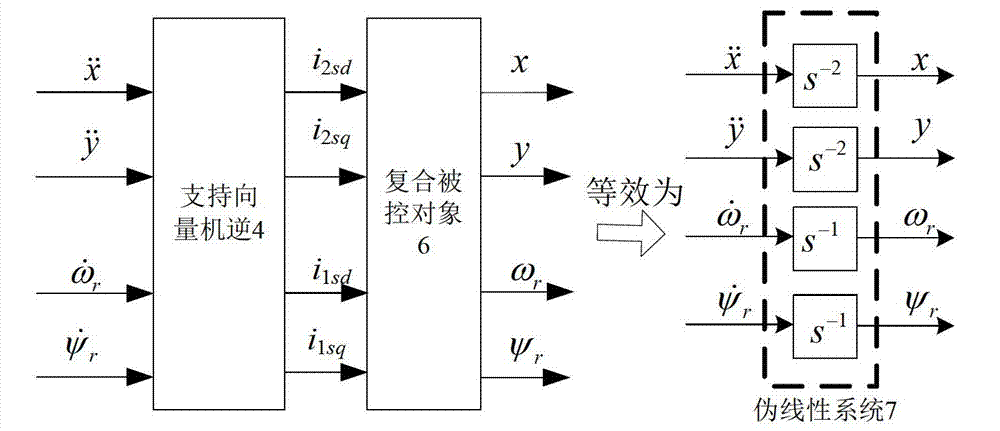

[0026] Such as Figure 6 As shown, the bearingless asynchronous motor control system based on support vector machine inverse is composed of closed-loop controller, support vector machine inverse model 4, first and second extended current hysteresis inverters 2, 3 and two degrees of freedom bearingless Composed of an asynchronous motor 1, the closed-loop controller adopts a multi-internal model switching controller 5; the first and second extended current hysteresis inverters 2 and 3 are connected in series before the two-degree-of-freedom bearingless asynchronous motor 1, forming a composite controlled The object 6 and the support vector machine inverse model 4 are connected in series before the composite controlled object 6 to form a pseudo-linear system 7 , namely the controlled object.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com