Method and apparatus for simultaneously manufacturing ultra pure betulin and highly pure betulinic acid from birch bark

An ultra-high-purity, betulinic acid technology, applied in chemical instruments and methods, separation methods, pharmaceutical formulations, etc., can solve the problems of non-disclosure, high production costs, and high solvent consumption, so as to save solvent usage and improve productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

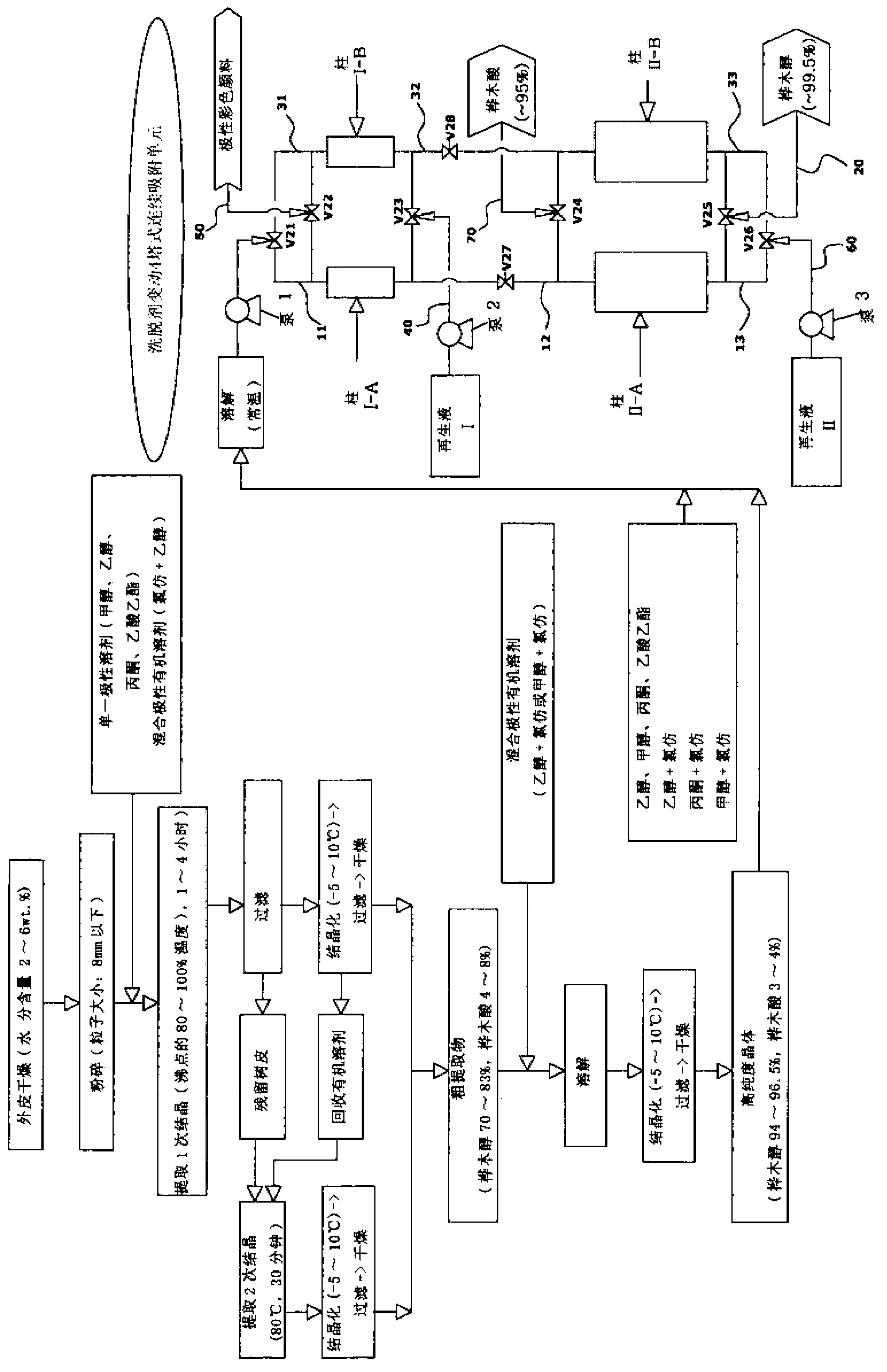

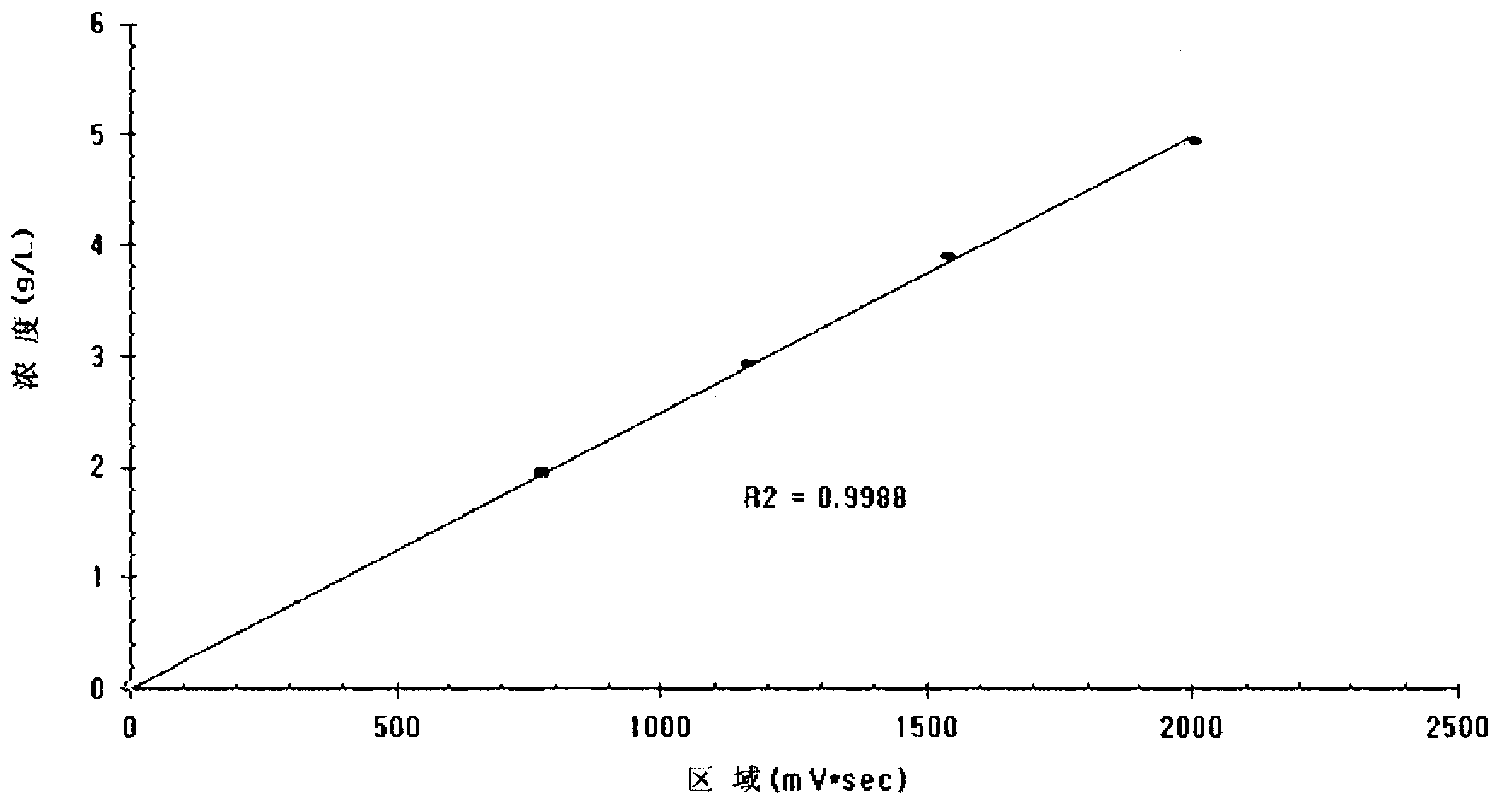

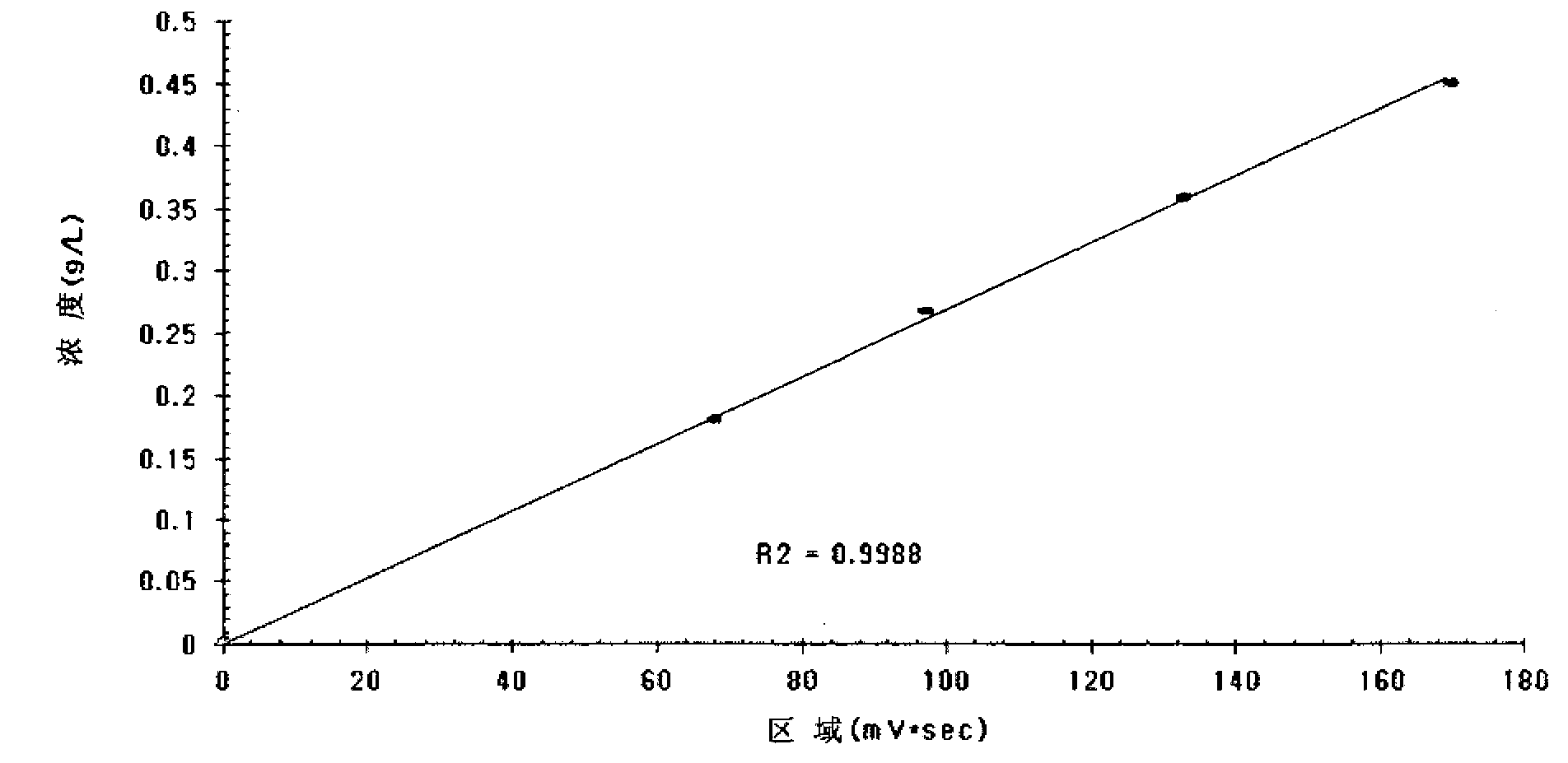

[0089] HPLC analysis of betulin and betulinic acid (calibration curve)

[0090] Utilizing the technology of the present invention, the concentrations of the crude extract, primary crystals, ultra-high purity betulin and high-purity betulinic acid are utilized figure 2 with image 3 The calibration curve (calibration curve) of betulin and betulinic acid was used for quantitative analysis. Betulin (Sigma: B8795, not less than 98%) and betulinic acid (Sigma: 855057, not less than 90%) were used as standard samples. Dissolve 100 mg of betulin as a standard sample in 20 mL of HPLC grade ethanol at room temperature to prepare a mother solution with a concentration of 5.0 g / L, and dilute the mother solution to obtain a concentration of 4.0 g / L and 3.0 g / L , 2.0 g / L samples were analyzed by HPLC. Dissolve 10 mg of betulinic acid as a standard sample in 20 mL of HPLC grade ethanol to prepare a 0.5 g / L mother solution for analysis, and dilute the mother solution to prepare 0.4 g / L, ...

Embodiment 2

[0092] Production of Crude Betulin Alcohol Extract from Betula Pulpwood Using Ethyl Acetate

[0093] The inner bark and outer bark of birch birch that grow naturally in North America were dried and pulverized so that the moisture content was 6%, and then 150 g of particles under 8 mm and 1900 mL of ethyl acetate were filled in a reflux extraction tank (the unit of outer bark per kg 12.67L), heated at 62°C for 1 hour and at 77°C for 3 hours under atmospheric pressure to extract betulin and betulinic acid into the organic solvent. The mixture contained in the reflux extraction reactor was subjected to high-temperature filtration (hot filtering) at 70° C. with a 0.5 μm PTFE membrane to prevent the solidification of betulin and simultaneously separate the organic solvent from the wet bark. 80% of the total volume of the filtrate was evaporated and the concentrated solution was left at -2°C for 10 hours to crystallize betulin. Betulin crystals obtained by filtering a mixture of be...

Embodiment 3

[0096] Production of Crude Betulin Alcohol Extract from Betula Paperbark Using Chloroform

[0097]Put 178 g of birch inner and outer bark (particle size below 8 mm, moisture content 5%) that mainly grows naturally in North America into a reflux extraction tank filled with 1900 mL of chloroform (10.67 L of chloroform per kg of outer bark). Heating at 49° C. for 1 hour, followed by heating at 61.2° C. for 2 hours, extracted betulin and betulinic acid into the organic solvent. In order to prevent solidification of crystals, the mixture contained in the extraction reactor was filtered at a temperature near the boiling point of chloroform. The organic solvent + extract was separated from the bark, 80% of the filtrate was evaporated, cooled at room temperature, and then left at -2°C for 10 hours to crystallize betulin and betulinic acid. The solid crystals obtained by filtering the crystals with a 0.5 μm PTFE membrane were dried at 35°C (primary crude extract), and 80% of the total...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com