Composite gel for plant capsules and preparation method for composite gel

A plant capsule and composite glue technology, applied in the direction of capsule transportation, etc., can solve the problems of high production cost, high storage condition requirements, low pass rate, etc., and achieve the effects of enhanced oxygen barrier effect, solution diversity, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

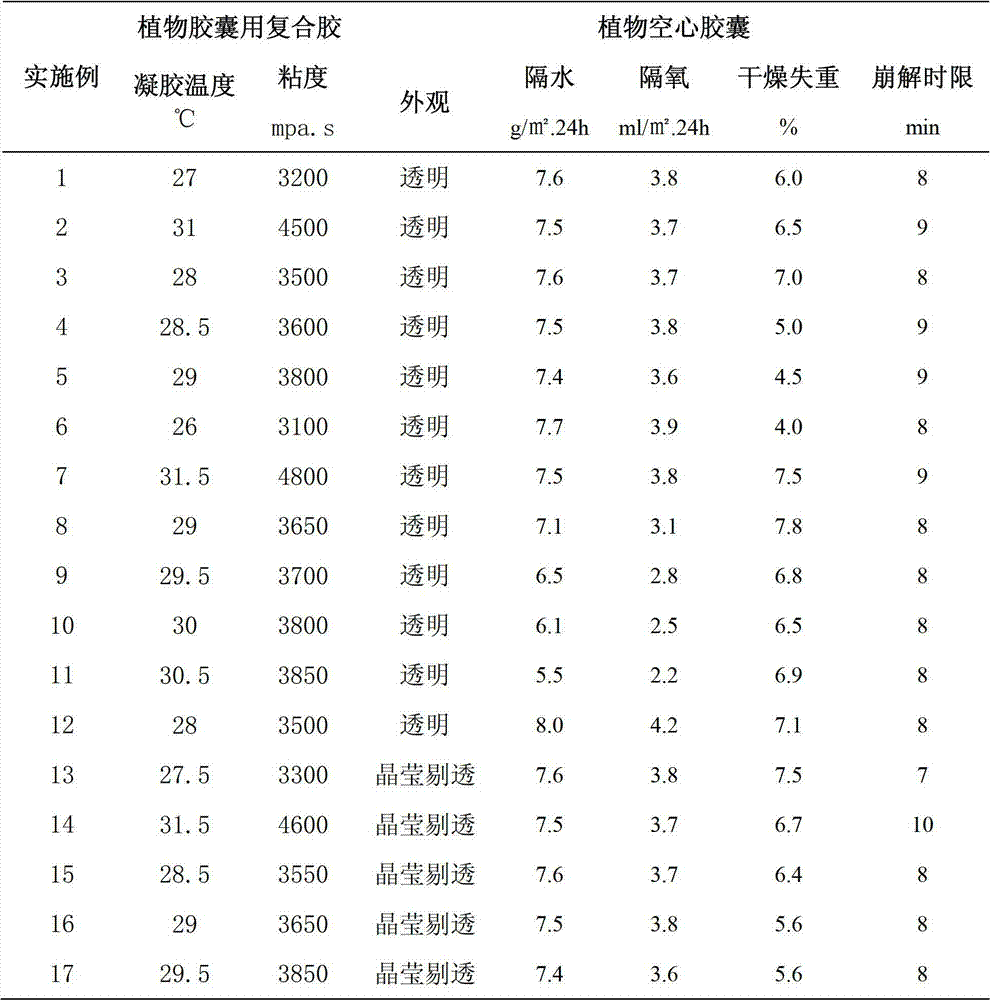

Examples

Embodiment 1

[0032] Weigh 3 kilograms of raw materials K-carrageenan, 1 kilogram of ι-carrageenan, and 96 kilograms of hypromellose, divide the hypromellose into two parts of 48 kilograms each, and then press 48 kilograms of hypromellose, 3 kilograms K-carrageenan, 1 kg of ι-carrageenan, and another 48 kg of hypromellose were placed in a two-dimensional mixer (volume 200 liters) and mixed in turn, and mixed for 5 hours until the vegetable gums were fully mixed and evenly mixed.

Embodiment 2

[0034] 10 kg of raw materials K-carrageenan, 1 kg of iota-carrageenan, and 89 kg of hypromellose were mixed in a three-dimensional mixer (200 liters in volume) for 2 hours, and the others were basically the same as in Example 1.

Embodiment 3

[0036] Raw material K-carrageenan 4.3 kilograms, iota-carrageenan 1 kilogram, hypromellose 94.7 kilograms, three-dimensional mixer (volume 200 liters) mixed 6 hours, other is basically the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel strength | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com