A 500kv post insulator live water washing method

A technology for post insulators and insulators, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as manual cleaning power outages, power supply stoppages of transmission lines, unsatisfactory problems, etc., and achieve high cleaning efficiency , avoid power failure loss, and improve the effect of insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

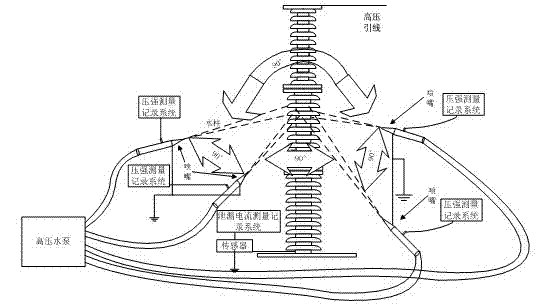

[0038] Firstly, introduce the tools needed to use the present invention, including four parts such as high-pressure water pump, high-pressure water pipe, high-pressure water gun, and deionized water. The high-pressure water pump can be a plunger pump or a centrifugal pump, and its output water pressure is between 0.5Mpa and 10Mpa. The pressure resistance of the high-pressure water pipe should reach 10Mpa or above. The high-pressure water gun is composed of a gun body, a high-pressure water valve, and a high-pressure nozzle. The gun body should be easy to operate by flushing personnel. The pressure resistance of the high-pressure water valve must reach 10Mpa or above. The high-pressure nozzle should have the characteristics of small pressure loss and small spray nozzle diameter. It should be between 1mm-30mm. The conductivity of deionized water should be between 1μs / cm-10μs / cm. The connection between the high-pressure water pump, high-pressure water pipe and high-pressure wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com