Laser welding word machine and welding word process

A letter welding machine and laser technology, which is applied in the field of letter welding machines, can solve the problems of wasting manpower and material resources, high technical requirements, and large processing volume, and achieve the effects of convenient movement, sufficient melting, and large welding depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance through the detailed description.

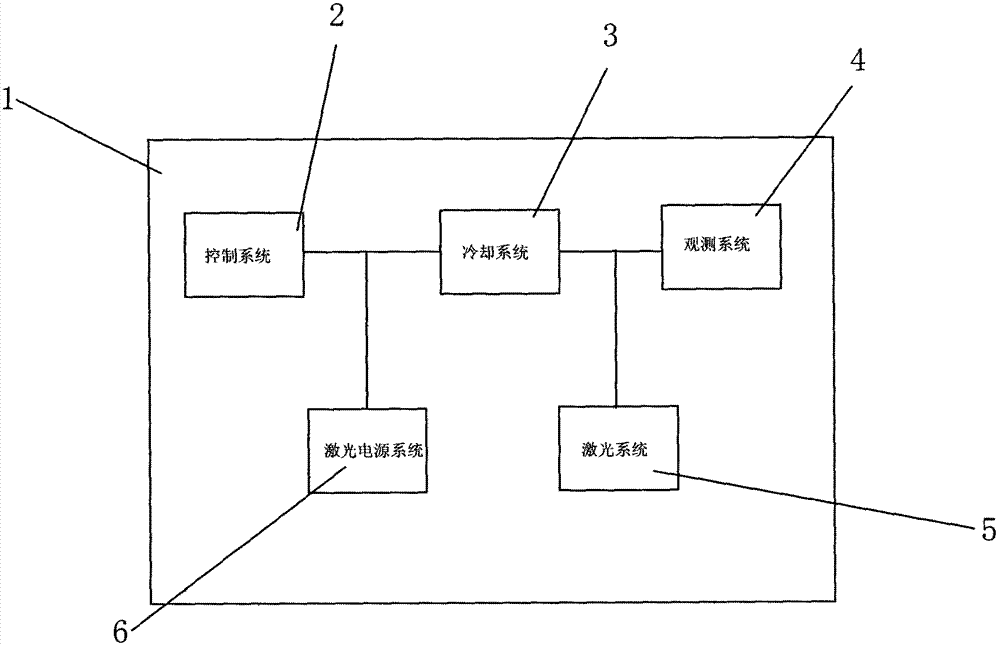

[0020] Such as figure 1 As shown, the present invention provides a laser welding machine 1, including a control system 2, a laser system 5, a laser power supply system 6, a cooling system 3 and an observation system 4; wherein the control system 2 is used for the entire laser welding The machine is controlled, which includes a control microcomputer system, an operation panel and a display screen; the laser system 5 is used to generate a laser beam and act on the surface to be worked to partially melt the material; the laser power supply system 6 is used to Provide power supply and set spot welding parameters; the cooling system 3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com