Environment-friendly thermal-insulation anticorrosion coating and coating process thereof

An anti-corrosion coating and environmental protection technology, applied in the field of environment-friendly thermal insulation anti-corrosion coating and its coating process, can solve the problems of increasing the cost of paint film thickness, unsatisfactory actual effect of coating film formation, poor thermal insulation effect, etc. , to achieve the effect of increasing cost, simple and practical coating process, and improving thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, further illustrate the present invention.

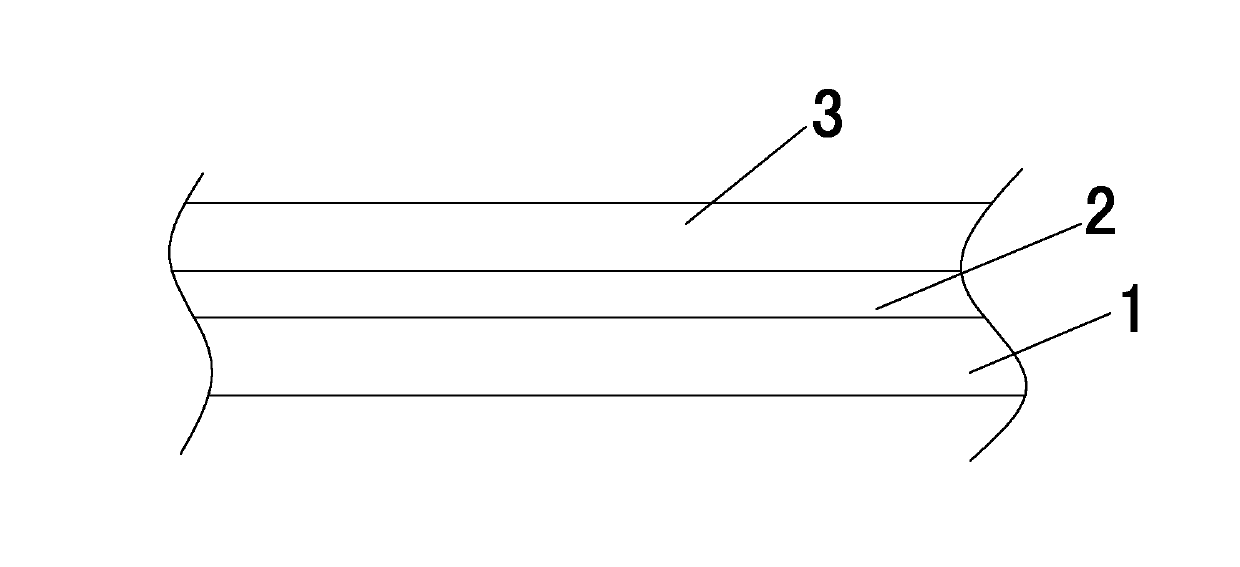

[0017] see figure 1 , the environment-friendly heat preservation and anticorrosion coating of the present invention comprises three layers of environment-friendly anticorrosion heat preservation layers 1, 2 and 3 with different characteristics; the bottom layer 1 is a high temperature resistant layer with a thickness of 230 μm; the middle layer 2 is an insulation layer with a thickness of 100 μm; The surface layer 3 is an anti-corrosion layer with a thickness of 200 μm. Forming a three-layer sandwich bonding structure, the thermal insulation and anti-corrosion functions are complementary, and the superimposed heat reflection is significantly enhanced, and the anti-corrosion and heat insulation effect is doubled.

[0018] The high-temperature-resistant layer 1 in the present invention is coated with high-temperature-resistant inorganic silicon primer, which can withstand high temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com