Star polycarboxylic-acid high-performance water reducing agent and preparation method thereof

A technology of polycarboxylate and water reducing agent, which is applied in the field of concrete water reducing agent, which can solve the problems of difficult performance, restriction of commercial concrete transportation radius, high water reducing rate of water reducing agent and high slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

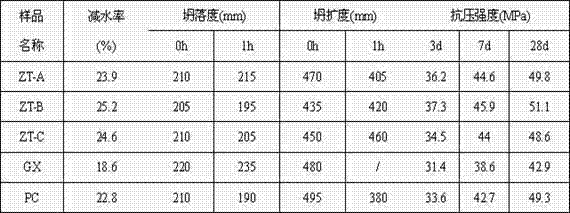

Examples

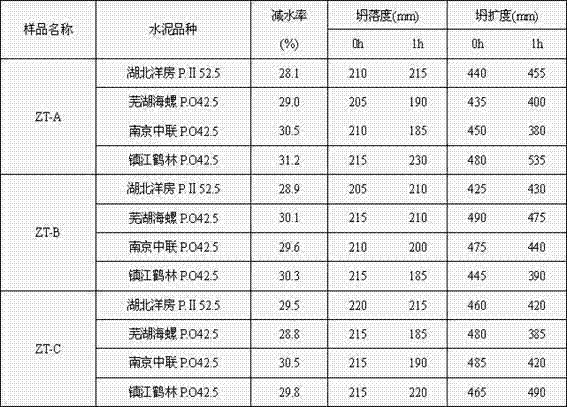

Embodiment 1

[0012] Add 12.5 parts of GL to a dry four-necked flask equipped with a stirrer, thermometer, condenser and water separator, and heat to 70°C under stirring; divide 35 parts of MAD into 3~4 times, adding slowly at 10 min intervals . After the feeding is completed, the temperature is raised to 110°C, the temperature is kept for 6 hours, and 20 parts of water are added to make a solution with a mass fraction of 70% to obtain a light yellow transparent liquid. Add 305 parts of TPEG and the prepared star monomer into a four-necked flask, add 460 parts of water and stir and heat to 90°C, 26 parts of AA and 5.8 parts of MAS, and 45 parts of water to make dripping solution A, 2.8 parts of APS and 1.5 parts MPA was mixed with 60 parts of water to make dripping liquid B, and the two dripping liquids A and B were slowly added dropwise respectively. After 3 hours of dripping, the temperature was lowered to below 40 ℃ after the incubation reaction for 2 hours, and 22 parts of liquid caustic...

Embodiment 2

[0014] Add 18.3 parts of GL to a dry four-necked flask equipped with a stirrer, thermometer, condenser and water separator, and heat to 70°C under stirring; divide 44 parts of MAD into 3~4 times, slowly adding 10 minutes each time . After the feeding is completed, the temperature is raised to 110°C, the temperature is kept for 6 hours, and 27 parts of water are added to make a 70% solution to obtain a light yellow transparent liquid. Add 290 parts of TPEG and the prepared star monomer into a four-necked flask, add 450 parts of water and stir and heat to 90°C, 28.5 parts of AA and 6.6 parts of MAS, and 45 parts of water to make dripping solution A, 3.1 parts of APS and 1.7 parts Add 60 parts of MPA with water to make dripping solution B, slowly add dropwise A and B respectively, dripping after 3h, keep the temperature for 2h, then cool to below 40℃, add 26 parts of liquid caustic soda to adjust the pH to 6~7, The finished product ZT-B is obtained after discharging.

Embodiment 3

[0016] Add 15.5 parts of GL to a dry four-necked flask equipped with a stirrer, thermometer, condenser and water separator, and heat to 70°C under stirring; divide 47 parts of MAD into 3 to 4 times, adding slowly at 10 min intervals . After the feeding is completed, the temperature is raised to 110°C, the temperature is kept for 6 hours, and 27 parts of water are added to make a solution with a mass fraction of 70% to obtain a light yellow transparent liquid. Add 280 parts of TPEG and the prepared star-shaped monomer into a four-necked bottle, add 428 parts of water and stir and heat to 90°C, 25 parts of AA and 4.6 parts of MAS, and 45 parts of water to make dripping solution A, 2.6 parts of APS and 1.3 parts Add 60 parts of MPA with water to make dripping liquid B, slowly add dropwise A and B respectively, dripping after 3h, keep the temperature for 2h and then cool to below 40℃, add 18 parts of liquid caustic soda to adjust the pH to 6~7, The finished product ZT-C is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com